A sustained period of elevated project costs is having a profound impact on the industry. The pressure to reduce costs while producing more and faster from increasingly complex fields is filtering through supply chains and changing the dynamics of buyer and supplier relationships.

According to IHS CERA, the cost of building and operating upstream oil and gas facilities held near record levels during the period 1Q 2013 to 3Q 2013. The firm's benchmarking analysis indicated a slight drop in upstream capital costs, driven by declining steel prices and a softening rig market. This was offset by a marginal increase in operating capital costs, led primarily by rising labor costs.

Following the brief leveling period, total upstream expenditure is expected to be back on upward trajectory this year. However, the consensus is that the spending will be carefully monitored as operators grapple with cost overruns and project delays. This, in turn, is compelling buyers to evaluate supply chain efficiencies.

The results of a recent survey by Martin Akel & Associates,The Oil & Gas Market: Integrated Media Dynamics, illustrates this trend. More than 1,800 readers of Offshore and Oil & Gas Journal responded to the PennWell-sponsored survey. About 40% are from oil and gas companies and 66% are management-level employees, all qualified as decision-makers.

A top challenge that survey respondents consider to be "significant" is the increasing pressure for efficiency and profitability. In response (among other reasons), 93% of buyers have made changes in their relationships with suppliers, especially in requiring vendors to provide greater proof of performance and cost estimates up-front. Moreover, an increasing number of suppliers are entering the market and buyers are finding it difficult to differentiate the products, the survey suggests.

As a result, most buyers are evaluating a broader range of options before purchasing. About 68% of respondents say they are likely to evaluate additional suppliers and technology before making a decision. The top five changes in the buyer and supplier relationship are:

- Now require suppliers to provide, up front, greater proof of performance, 60%

- The evaluation of suppliers and technology is now more rigorous and analytical, 59%

- Now require suppliers to offer more support (tech support, maintenance, etc.), 58%

- Now require suppliers to be more accountable for their technology, 57%

- Now require suppliers to stay more involved after the sale (implementing, training, consulting, etc.), 55%.

A recent survey by DNV GL,Challenging Climates: The outlook for the oil and gas industry in 2014, echoes these and other impacts from rising costs. About 62% of its survey respondents "intend to pressure suppliers to curb cost increases this year." The same proportion of respondents "admits to strong pressure within their business to safely extend the lifespan of their existing assets and increase the return from these investments," the report says.

As a means of controlling costs, the DNV report suggests that there is a renewed interest among its survey respondents in seeking greater supply chain efficiencies. The report points to three broad trends: tougher cost negotiations among buyers and suppliers; more reliance on bigger supply chain partners to standardize and streamline a global approach; and requiring greater consistency in quality and risk management.

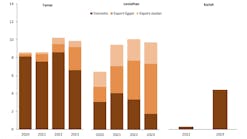

Meanwhile, authorsMichael Haney, Matthew Loffman, and Steve Robertson of Douglas-Westwood, believe that the FPSO supply chain is broken. "Markets will be unable to meet FPSO demand over the next five years unless significant change occurs in an industry increasingly defined by schedule delays and cost overruns," they say in a special report inside this issue. The authors, beginning on page 52, quantify these delays and cost overruns and examine the reasons behind their premise.

To respond to articles in Offshore, or to offer articles for publication, contact the editor by email([email protected]).