From hand sketch to unique solution

Lee Avery, Bruce Morris - Quality Connector Systems

Piggable wyes have been used extensively in deepwater oil and gas pipeline operations to allow cleaning and inspection pigs and intelligent pigs access through main lines and the laterals that tie into them. Being able to run these state-of-the-art pigs through the wye improves the operating efficiency and the long-term integrity of the pipeline system. Although wyes improve operations on some levels, there are cases when operators need to run pigs counter to the normal flow direction in the lines. This presents no problem in a pipeline with no piggable wyes, but the internal profile at the wye fitting juncture does not permit reverse flow pigging.

Quality Connector Systems (QCS) has developed the Director Bi-Directional Wye to address this industry requirement.

Traditional piggable wye operations

Operators of oil and gas pipelines wage a constant battle against the harmful effects of internal corrosion, paraffin, and condensate accumulation. Commonly accepted practice dictates that the operator run pipeline pigs through the line. The pipeline product flow pushes these cleaning devices through the length of the line. The pig maintains contact with the internal wall of the pipe, pushing hydrates, paraffin, condensate, and other potentially harmful agents in advance of its passage through the pipeline. Corrosive elements are removed from the line at its termination point, enhancing the long-term integrity of the pipeline.

Pigging a single line is a straightforward process, requiring only that the pig be launched from one end and pushed the length of the line using a liquid or gas medium as the propelling force until it is captured in the pig receiver at the end of its journey. However, pigging lateral line tie-in connections requires that the operator pre-plan the installation of a piggable wye fitting in the main line during the construction process. A piggable wye is a Y-shaped fitting that has two inlets, one for each incoming pipeline, and a single outlet that merges the flow of the two converging pipelines. The two lines converge in the Y at an intersecting angle of 30°. This basic wye configuration was originally tested in the 1980s and has proven to be a reliable design.

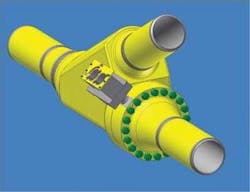

A piggable wye is a Y-shaped fitting that has two inlets, one for each incoming pipeline, and a single outlet that merges the flow of the two converging pipelines. This view is the ROV-operated option.

For years, the question has been whether it would be feasible to run pigs backward through a wye from the outlet through one of the inlets in a reverse flow pigging application. Until now, the answer has been no.

The internal profile of the wye at the juncture of the two pipelines would likely cause the pig stick in the fitting. Alternatively, if the pig managed to traverse the juncture area of the wye, there would be no way to determine which of the two converging pipelines the pig would flow into.

Bi-directional pigging

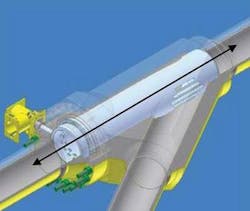

A recently developed product now allows pigs to run forward or backward through a wye. The Director Wye has the unique ability to accommodate reverse flow pigging. This new direction in piggable wye technology uses an internal diverter sleeve that is actuated from the exterior of the wye. The diverter can be actuated by an ROV or diver. The internal diverter sleeve rotates within the mainline bore of the wye to direct the pig.

The open position permits normal pigging operations that originate through the main line and/or the lateral line that converges into the single main line downstream of the wye. When the internal sleeve of the Director Wye is rotated to the closed position, the barrel of the sleeve closes the access port within the wye from the lateral line to the main line. Conventional pigging can still be conducted through the main line in the closed position, but the diverter sleeve allows a pig to run in the reverse flow direction through the main line as well. With the lateral line bore closed, the pig cannot jam in the juncture of the wye and cannot inadvertently enter the bore of the lateral line.

The Dual Director Wye

The Director Wye had no more entered the market than an operator asked if the design could be modified to permit bi-directional pigging through both the main line and the lateral legs of the wye. The Dual Director Wye accomplishes this feat through the addition of a mirror-image internal diverter sleeve in the lateral leg of the fitting.

The Dual Director Wye permits bi-directional pigging through both the main line and the lateral legs of the wye.

Like its predecessor, the Dual Director can be used as a standard wye with both diverter sleeves in the open position. When the main line diverter is operated to shut off access to the lateral opening, the Dual Director also permits bi-directional pigging through the main line. The differentiating feature of the Dual Director is that if the mainline sleeve closes the main line and the lateral line sleeve is open, bi-directional pigging can be accomplished through the lateral line. The design of the dual internal diverter sleeves and the actuation system is the same for both the Director Wye and Dual Director Wye.

Concept to reality

The Director Wye was initially proposed to a client by means of a hand sketch on a marker board. That rough sketch led to the final product.

An operator planned to commission a pipeline by flushing the water from the line using a pig from the platform to a subsea pig receiver. The plan required that a second operation be performed to remove the subsea pig receiver and to make the final tie-in to a wye on the pre-existing pipeline. This approach entailed several technical and environmental difficulties and was costly in the deepwater environment.

The Director Wye allows the operator to make the subsea connection to the existing pipeline first. Then, the pipeline can be dewatered by opening the valve at the subsea tie-in point and using the pipeline product to push a pre-installed pig in a reverse flow direction through the Director Wye all the way to the platform. Reportedly, this innovative approach will simplify the operational process and reduce commissioning costs for the pipeline.

Future applications

There are other potential applications for the Director Wye, many of which offer benefits to shallow-water and onshore operators. Potential applications for the bi-directional piggable wye include:

- Deepwater tie-backs: Standard practice for deepwater subsea tiebacks dictates the installation of dual pipelines to permit roundtrip pigging of the lines. In many cases, the dual lines are several miles long. The installation of a Director Bi-Directional Wye would enable the operator to install a single line and still be able to pig the system. The pig would enter the wye in the reverse flow direction on its way to the wellhead. The internal director sleeve would be rotated to permit the pig to enter the lateral leg of the wye in a standard flow direction and traverse the wye on its return journey to the platform. Eliminating the redundant flowline reduces capital expense. This procedure also reduces the number of marine risers on the platform to a single riser.

- Permanent reverse flow projects: In certain cases a subsea pipeline system is designed to accommodate a future need to use reverse flow to provide feed gas for offshore operations from an onshore processing facility. In this case, the wye functions as a standard wye as long as the offshore structure can produce enough gas for its operational purposes. Once this is no longer the case, the internal sleeve of the Director Wye can be rotated to permit reverse flow of the product and any required pigging operations to one or more offshore structures.

- Coiled tubing access for deepwater risers: A Director Wye could be installed topside in a marine riser to permit more efficient coiled tubing access. The wye would be installed such that pigging the riser and pipeline could follow the conventional flow. The internal director sleeve would be rotated to close off access to the lateral leg of the wye. When coiled tubing access is required, the internal director sleeve would be rotated to open access to the lateral and permit the installation and withdrawal of the coiled tubing. At the conclusion of the operation, the internal sleeve would be rotated again to close off the tubing access lateral opening to permit pigging of the riser once again.

- Onshore applications: The Director Wye would permit the use of intelligent pigs alternatively through either the main line or the lateral without compromising piggability in either line.