HIGH STRENGTH PIPING: Composite/steel pipe designed for extended service in hostile conditions

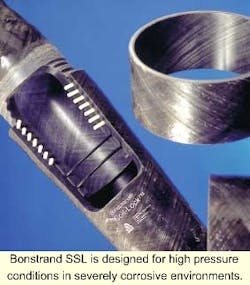

A new high pressure pipe has been introduced for high pressure, high corrosive environments. The Bonstrand SSL (Steel Strip Laminate) pipe, developed by Ameron International, incorporates SSAB Swedish Steel's ultra high-strength steel, Docol 1400 DP, sandwiched between a conventional glass fiber-reinforced epoxy (GRE) composite on the interior and exterior of the pipe wall.

The Docol 1400 DP steel layer, which consists of 100.4 mm wide and 0.5 mm thin steel strips, is wound diagonally onto the inner GRE core layer. According to Managing Director of the Ameron Fiberglass Pipe Group, Peter Tolhoek, the new pipe provides the best of both worlds: "In addition to the strength of the steel, we make use of the resistance to corrosion which is an important feature of the glass fiber-reinforced epoxy. The result is a pipe which can withstand extremely high pressure in environments exposed to corrosion."

In addition to its good mechanical properties, the Bonstrand SLL pipe is being manufactured at around a third of the cost of an all-epoxy pipe designed for the same pressure capacity. It is also claimed to be cheaper to manufacture than stainless steel pipes, with a service life of at least 30 years compared with an estimated six months to three years for stainless steel pipes in similar corrosion conditions.

Crude pipeline

"The need for even lighter pipe wall designs which can withstand high pressure conditions is increasing all the time," continues Tolhoek. "We have made a new production line for winding the steel strips and we have developed a non-welded joint for high pressure where the pipe ends are inserted into each other and are connected using O-rings. The joints are protected against corrosion by epoxy treatment."

According to Ameron, this joining method facilitates speedy assembly, which in turn helps reduce costs. The new pipe is manufactured in diameters between 200 mm and 1,000 mm, and is designed for pressures of up to 400 bar.

"Our aim was to enter the considerable pipeline market for crude oil, as suppliers," says Tolhoek. "But we would then need to produce a stronger pipe and one which was not too expensive to manufacture. Epoxy and glass fiber are extremely costly materials and in order to withstand higher pressure we would need to increase wall thickness, which would make this kind of pipe too expensive for the market."

The idea of combining the GRE with steel came from the rocket industry where this technology is used for rocket engine casings. The US-based Ameron initiated and managed the new pipe project which took five years to develop from its plant in The Netherlands. As a result of including the SSAB high-strength steel, the weight of the Bonstrand SSL pipe is 75 % less than a pipe made entirely of glass fiber and 60 % lower than a stainless steel pipe. The reduced weight also helps to reduce transport and labor costs.

The design has been awarded the Swedish Steel Prize which was instituted for engineering designs in which high strength steels are used.

For more information contact Karl-Inge Nillson, SSAB Swedish Steel: Tel +46 0243 71023, Fax +46 243 71550, e-mail [email protected]