MPD and closed-loop techniques solve drilling challenges off West Africa

Marc de Boer

Essam Sammat

Stephen O'Shea

Weatherford

A complex set of challenges offshore West Africa has defied drilling efforts for more than 40 years. Multiple attempts in the area's high pressure/high temperature and regressive pressure regimes using conventional methods have been unable to construct a wellbore to total depth.

The solution came with an unusual scope of managed pressure drilling (MPD) operations and closed loop well construction techniques. Conducted successfully in both the 12¼-in. and 8½-in. sections, the MPD and closed loop drilling involved rarely used operations including statically underbalanced coring, closed loop wireline logging, statically underbalanced liner running, and statically underbalanced liner cementing.

Reaching the Isongo

The primary objective of the gas well in the Etinde field was to reach the top middle Isongo reservoir sand at approximately 10,335 ft (3,150 m) measured depth (MD). Doing so required drilling within a very narrow window between pore pressure and fracture gradient.

In prior experience dating to the 1970s, drilling had been severely challenged due to loss of pressure during drilling pipe connections. This, in turn, set in motion well-threatening kick/loss cycles, and major variations in the pressure gradient at different depths.

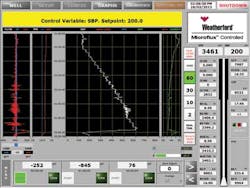

MPD overcame these conditions by using a lower mud weight and managing downhole pressure with the combined effects of equivalent circulating density (ECD) and surface backpressure (SBP). This was achieved using a rotating control device (RCD), an MPD manifold, and other associated equipment to create a closed loop circulation system. The closed loop system enabled greater control of the wellbore pressure using an automatic choke and algorithm-based well parameters that make up Weatherford's Microflux control system. A Coriolis mass flow meter provided accurate flow monitoring to enable the rapid identification of losses and gains within the closed loop system.

The static mud weight of 12.9 to 14.2 ppg in the 12¼-in. section and 14.2 to 15.5 ppg in the 8½-in. section would have been statically underbalanced in conventional drilling. To use the lower weight mud, ECD and/or SBP was required at all times to maintain bottomhole pressure (BHP) within the drilling window above pore pressure and below the fracture gradient. The operating target was to remain at least 100 psi above the pore pressure gradient at all times while drilling and during connections. For tripping operations, a heavy mud cap was planned at a suitable depth to balance the well without SBP to allow removal of the RCD bearing assembly.

The purpose of implementing MPD was to manage the borehole pressure profile to reduce the chance of well control events. Other goals included increasing wellbore stability, mitigating stuck pipe, and precisely determining and managing the drilling window between pore pressure and fracture gradient. Its use on this well had a significant impact on time and cost savings by greatly reducing expected swab surge problems, and enabled non-drilling operations such as coring, closed loop wireline, liner running, and cementing.

Pre-job modeling had indicated that these operations might not be conventionally possible. The rapid speed in which the ECD can be adjusted via minor changes to the Microflux system also saved time that would have otherwise been spent circulating fluids out of the hole and changing the mud density. This capability alone delivered a significant cost savings over previous drilling operations in the region.

The sensitivity of the MPD system enabled rapid identification, decision-making, and reaction to drilling events, which boosted safety and accuracy, and enhanced confidence in decision making. The application of SBP to a statically underbalanced mud was a key strategy in controlling and applying constant bottom hole pressure (CBHP) in the 12¼-in. and 8½-in. sections. SBP was applied during pumps off events when ECD was not affecting the annular pressure, as well as during drilling to compensate for the shortfall required to stay in the drilling window.

MPD operations

In planning a return to the field, the historic drilling problems and downhole uncertainty led the operator to implement the full scale MPD and closed-loop approach to well construction. These problems were amplified by abnormal pressures, high temperatures that made the mud difficult to condition and control, very low kick tolerance, and the need for a rapid response to mud weight (MW) requirements.

The MPD system, including a mud gas separator (MGS), was installed on the small jackup with no modifications. MPD operations began with fingerprinting to identify expected pressure trends, and in-casing tests to confirm and fine-tune system operation. Tests in cased hole were performed prior to drilling each new section to establish limits and procedures.

While not needed to drill the 12¼-in. section, MPD was conducted to provide operational exposure as well as to familiarize and train the rig crew. MPD operations differ from standard drilling operations and crew performance, and communications are important to smooth MPD operations. For instance, it is necessary to gradually ramp down the pump rates when making connections to allow MPD to compensate for the change in ECD.

The 12¼-in. section was drilled with statically underbalanced mud of 12 to 9 ppg with bottomhole equivalent circulating density (BHECD) ranging from 14 to 14.6 ppge. There were no well control events and a stable drilling window was maintained through the 1,263 ft (385 m) drilled. Although MPD was not needed, it was able to provide valuable data that was not available from logs. The section provided the first opportunities to conduct dynamic leak off tests (DLOT) and dynamic pore pressure determination tests (DPPDT).

During MPD operations in the 8 ½-in. section, there were five minor well events that resulted in closure of the annular preventer. Each was related to either equipment failure or anticipated high gas levels resulting from operation activities. In the first instance, a top drive system swivel packer failure resulted in a decision to pull back five stands of pipe to the shoe. The pipe movement resulted in swabbing and masked volume outflow trends. The second event involved a rig power failure, and event three occurred when gas levels reached 29% at the mud loggers and 58% at the Weatherford GC-Tracer gas chromatograph located downstream from the choke manifold and upstream from the MGS. Gas was expected due to testing procedures and connections, and was not the result of a gas influx. Event four was precipitated by line vibration that sheared crossover pipework, and event five occurred when the pump feed failed.

Critical testing

Use of DLOT and DPPDT was critical in defining drilling window limits. The data informed decisions on what BHECD to hold. Hole strength was also improved with stress gauge material pumped in a DLOT mud squeeze.

In conducting DLOTs, connections were carried out with SBP automatically increasing to replace frictional losses and maintain constant BHP as mud pump pressure was reduced. SBP was achieved by flowing the auxiliary pump through the MPD chokes. As much as 1,200 psi SBP was required when the mud pumps were fully stopped.

The DLOTS were performed using rig pumps to pump through the bit while rotating the drillstring. This method results in lower required surface pressures, which enhances safety and surface equipment life. The MPD system provided SBP to eliminate non-productive time (NPT) and use of the BOP. Flow meters in the MPD system confirmed the fracture gradient by recording small fluid losses. DLOTS were conducted several times in a section to measure the weakest point rather than assuming the casing shoe was the weakest point.

Similarly, DPPDT were performed using mud pumps and rotating the string. No additional MPD rig up was required. Surface pressure was reduced in stages until a small influx was seen via the flow meter. The influx was safely circulated out of the well through the MGS. Along with DLOT, the test was valuable in determining the actual drilling window.

Rare operations

Relatively rare closed loop coring operations were performed in the 8½-in. section. The closed loop system was used to maintain early kick loss detection (EKLD) and keep BHP constant during coring. The system had no affect on the coring operations. Extra tripping with a large gauge BHA was required and swabbing was counteracted with SBP after a mud cap was placed.

Closed loop wireline, also a seldom-used operation, contributed significantly to the safety of operation. The system was used to maintain EKLD and prevent swabbing when pulling out of the hole by applying SBP. The closed loop system was created without using rig well control equipment and while allowing the rig to maintain flow detection capabilities. In addition, the RCD provided a solid anchor for the wireline grease head.

Closed loop statically underbalanced cementing was also performed on the well. Cementing involved varied surface pressures due to different fluid weights in the hole to maintain constant BHP. The closed loop system yielded more precise spacer and slurry displacements, and enabled detection of induced fractures while cementing. Annular backpressure, applied using a choke or backpressure pump, allowed pressure to be adjusted throughout the cementing process.

Unconventional solutions

Drilling the West Africa well was a challenge that had stood since the 1970s, when it became obvious that conventional drilling methods were not adequate for the task.

The application of MPD methods and closed loop drilling technology provided an unconventional well construction solution. The successes and versatility of the project provides a path forward for many prospects that have previously been undrillable.