PART I: This is the first in a two part series addressing tough high pressure/high temperature (HP/HT) shallow water drilling projects around the world.

Part I focuses on new "big" jackup designs and the associated enhancements to tackle this difficult niche market. Part II will present a HP/HT well drilled successfully in a known well construction problem area.

A movement back into shelf properties has taken place over the past several years, primarily to address supply shortages - mostly natural gas - in more cost effective, lower risk prospects. This drive has increased activity in offshore blocks where difficult pockets of geology have historically presented major headaches to well planners.

Multiple drilling attempts by various operators often result in a long drawn-out learning curve, which can be extremely costly. The High Island blocks in the Gulf of Mexico are no exception to this scenario. Certain blocks in this offshore area notoriously give drillers problems. Long extended periods in well construction activities often result in failure to complete the well. Wasted time and money are the result; the only benefit is what not to do on the next well attempt.

Aging jackup fleet

A majority of the jackup rigs working in the Gulf of Mexico are at least 20 years old. These rigs are not equipped for the HP/HT projects now being undertaken in other areas of the world. Heightened interest in environmental and more ergonomic processes are also working to render these rigs obsolete.

A new innovation to an existing rig design is proving successful in these tough, previously un-drillable High Island wells. The rig was designed for a growing niche market - deep, HP/HT drilling. Increased productivity has been achieved, with improved safety features for employees.

One of the most popular jackup designs today is the standard LeTourneau 116C. There are three rigs of a new enhanced version of thisdesign, the Super 116, drilling in the Gulf of Mexico: Chiles Columbus, Chiles Magellan, and Chiles Tonala. A fourth rig is being built in Singapore. This rig is a Keppel-Fels Mod V "B" design and is scheduled for delivery in early 2002.

Jackup specifications

The new Super 116-design jackups are extended-reach cantilever rigs capable of operating in 360-400 ft water depths. The closed loop mud system has been improved, with mud pumps capable of 6,600 total hhp (hydraulic horsepower), a pumping capacity of 2,200 gpm, and a maximum operating pressure of 7,500 psi (5,000 psi practical maximum operating pressure).

By comparison, standard rigs can yield only 3,200 total hhp, 1,200 gpm, and 5,000 psi maximum operating pressure (3,500 practical maximum psi operating pressure). This accounts for almost 100% increases in total hhp and pumping capacity, and a 50% increase in maximum operating pressure.

Mud volume capacity has increased 150% from 1,600 bbl (average) on standard rigs, to 4,200 bbl total storage volume - with the capability of three different mud systems in the tanks at one time. The hydraulic system piping from the pumps to the standpipe goose neck is 5 1/2-in. ID (7 5/8-in. OD) steel tubing with a operating pressure capable of 7500 psi.

These new rigs are 100% zero discharge. An auger can easily be installed for cuttings collection purposes. Available space for deck storage and cuttings disposal containers has been increased on the Mod V "B" by designing the living quarters wrapped around the bow leg. This has freed up about 50% more space for storage purposes.

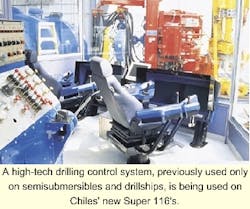

Drilling control system

These jackup rigs are some of the first to use technology originally designed for deepwater rigs. The automated, Hitec Cyberbase drilling system features all digital monitoring and control systems. William Chiles, Chiles Offshore President and CEO, posed the question: "Why go to an all digital system?" Because it "is safer, not necessarily faster, but the response is more consistent and smooth, helping eliminate the train wrecks sometimes encountered in the drilling process," he explained.

An added benefit of a more automated, digital control system is in collection and transmission of data to operating companies on the rig and onshore. Standard microwave communication is available. Satellite linkup can be obtained with several hours notice.

To assist drillers, automatic limits for upper and lower block positions are controlled. Alarms for setting and re-setting crown savers are present to remind the driller when these operations are to be performed.

The conversion to more automated drilling control systems required intensive training for the drillers. Two weeks of simulator training in Houston were required to introduce the drillers to the capabilities of this more automated system. An average of 30 days on-the-job training also was required to bring the drillers up to the level where operating efficiency was at least 90% of the system's estimated optimum.

Pipe handling automation was considered in the design phase, but cost effectiveness was not deemed satisfactory to implement in the US Gulf of Mexico. Dual pipe handling capability, however, was designed into the rig floor work flow. Bottom hole assemblies and stands of drillpipe can be made up off the critical path, with a rotating mouse hole and dedicated torque tool. This helps eliminate the need for an iron roughneck. Two mouse holes, 30 ft and 60 ft respectively, are available for simultaneous operations.

To allow for possible future addition of automated pipe handling equipment, the 1.5 million lb hookload capacity derrick allows ample space and configuration area for expansion. The rig floor area is 32 ft by 35 ft, versus a 30 ft by 30 ft derrick base on standard jackup rigs. This seemingly small increase allows for a substantial increase in derrick space for racked drillpipe. Approximately 30,000 ft of 5 1/2-in. drillpipe can be stored in the derrick, versus 20,000 ft of 5-in. drill pipe on standard rigs. The derrick can hold up to 25,000 ft of 5 7/8-in. drillpipe if preferred.

Flexible kelly hoses are larger, and of higher pressure rating, than on standard jackup rigs. One interesting effect of operating at higher fluid pressures has been the stiffening and expanding of the hose. This stiffening affects the bending radius of the hose and puts a higher than normal side force on the top drive. The result has been a slight but noticed increase in top drive roller wear, requiring more frequent inspection of the top drive track and roller system.

Other top drive hydraulic and mechanical connections are also being more frequently inspected to insure components are not being fatigued pre-maturely. The swivel packing on the top drive has shown accelerated fatigue characteristics. A new compensated pressure system by National has helped minimize the pressure differential across the seals in the packing, to minimize this wear.

Well control capability

Well control capability has been enhanced on the new rigs with use of the Cameron TL, 13 5/8-in., blowout preventer (BOP). The TL is light in weight, and can be stored/handled in one piece with all hoses connected in place. Testing and nipple-up operations can be performed on the storage stump, reducing the amount of rig time required to install the BOP on the wellhead.

Nipple-up times have decreased from 12-13 hours to 2-3 hours. BOPs as large as 21 1/4-in. and 5,000 psi rating have been used on the Columbus. Flexibility for larger stack use has been designed into the rig. For example, an 18 3/4-in. BOP can be handled with no extra modifications. In fact, three of the wells since last June have required a bigger BOP stack.

To accommodate the flow rates required for the larger BOPs used on the rigs, an ABB/Koomey Minute Man control system has been installed. The system is similar to the subsea control system (pod on the stack) used on deepwater rigs.

Crane lifting capacity for the rigs has not changed much from standard design. Three cranes at 50-ton capability each, are positioned in standard configuration around the rig. Drilling crew staffing has not been changed, thus the living quarters accommodates the standard 84 people.

Future applications

The HP/HT capabilities of this rig design make it the ideal alternative for underbalanced (UBD) drilling operations. The added deck space for pressure control, collecting, and pre-processing equipment used in the UBD processes, provide a distinct advantage in this type of drilling operation for the design. As Gulf of Mexico operators more seriously consider the UBD process in this region, the availability of sufficient, capable drilling rigs will speed up the decision to use UBD processes.

Acknowledgement:

William Chiles, President and CEO of Chiles Offshore, contributed to the development of this article.