DRILLING TECHNOLOGY: How mud logging has changed to accommodate deepwater drilling

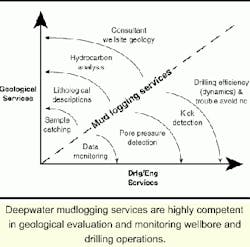

Deepwater mudlogging services are highly competent in geological evaluation and monitoring wellbore and drilling operations.

The emphasis on deepwater, high cost and high profile wells has put new demands on what was traditionally considered the mud-logging unit. Not only are the mudloggers expected to maintain high levels of competence in geological evaluation, they are also expected to monitor the wellbore and the drilling operation.

There are many reasons to mud-log a well. The geologist will say the loggers are there to keep an eye on the drilling department, to keep track of where the well is, to spot the hydrocarbons, and obtain good cuttings samples in case the wireline logs fail. The engineers and drillers have different reasons:

- Keep an eye on the geology department and the drill crew

- Provide additional safety measures

- Watch pits for kick detection

- Call out the gas

- Get detailed morning reports

- Government regulations.

Petrophysicists, geochemists, and micro-paleontologists often want mudloggers out there. They may want help in interpreting wireline logs, to get meaningful samples for analysis, or to get real time data. An all-around mud logging company often performs the multiple tasks associated with drilling services at the wellsite. The goals of mud logging companies, in line with those of oil companies, should be to maximize the information necessary to make informed geological and engineering decisions in a timely manner to ensure safe, cost-efficient discovery and production of hydrocarbons.

A properly equipped mudlogging cabin on location can help avoid costly trouble time.

Since the mid-1980s, services have grown to include information management as well as the drilling and engineering aspects of well construction. Now, mud-logging companies also monitor drilling operations and the various parameters that affect those operations. Data is collected via sensors on the rig to ensure that drilling is being conducted efficiently.

Checks and balances

Mud-logging services can be classified into four distinct types:

- Standard, or basic, mud logging

- Data monitoring services

- Advanced data monitoring services

- Integrated services.

Standard mud logging may not be offered as an option, especially from more sophisticated companies. Nevertheless, in deepwater locations, the traditional standard operation should be observed, such as examining rock samples under a microscope and evaluating gas circulated up from the wellbore. To qualify a standard service, one must consider several checks and balances.

- Does the rate of penetration curve match the gamma ray curve? If not, was the drilling noted on the log as "controlled?"

- Does the lithology represented match the gamma ray curve? If a roller cone bit was used, the sands should drill faster. A polycrystalline diamond compact bit will often have a reverse drill break.

- Does the gas curve match the resistivity curve?

- Does the total gas curve match the chromatograph? Although not exact, the gas detector and chromatograph should be good indicators of potential hydrocarbon activity.

Other concerns

For conventional data services, further considerations apply.

- Are the sensors working properly? Do the loggers report calibration procedures? Do the loggers report down time on sensors? Is the company responsive to getting replacement parts to location in a timely manner?

- Does the rig-up meet or exceed regulatory requirements (MMS and Coast Guard in the case of the US) by way of cabling and automatic shut-down systems? Do the units have internal gas detectors with automatic shut-down?

- On advanced data jobs, is the data automatically entered into the database or is it hand entered? Is there both a time and depth database? Usually, this service level includes some form of pore pressure analysis.

- Is the manager informed in a timely manner of over-balanced or under-balanced conditions? Have there been any unexplained kicks?

- Was the pore pressure taken into account when evaluating shows? What is the gas system used on this upper level service? At the very least, there should be an FID chromatograph with a data integrator and total gas system automatically recording all data on a per foot and per cycle basis.

- On integrated jobs, is there a combined, daily real-time integrated measurement-while-drilling (MWD)/mud log, or must the logger wait until the MWD tool is dumped for memory? Do the loggers handle transfer of all data in a timely and convenient manner? Do the combined services work together as a team in reporting potential shows, pressure evaluation, and hole conditions?

- For all service levels, is the final well report a document that could be used for future well planning?

Service standards

A mud-logging company can perform a wide spectrum of services that interface with both geology and engineering. At the lower levels, these services are considered low-value and low-cost. They are typified by sample-catching services and simple data-monitoring services.

The next step up includes lithologic descriptions and pore pressure detection. Next would be hydrocarbon analysis and automated kick detection services. Finally, there is the high value, high-cost service including a wellsite geologist and drilling-efficiency consultant.

The mud-logging company should adhere to the standards and practices as outlined by the Society of Professional Well Log Analysts (SPWLA). In 1983, the SPWLA set forth recommended practices for mud-logging services. Standards were set up for log formats, units of gas measurements, calibration standards and performance checks, description format and abbreviations, and oil show detection methods. These should be the minimum accepted standards.

In areas where pressure evaluation services take precedence over the geological services, pressure evaluation services are performed in addition to the geological services. These services often require additional sensors and personnel at the wellsite.

Pressure evaluation services also involve the continuous monitoring and plotting of different parameters versus depth, then looking for deviations from the "normal" trends. Information concerning changes in formation pressures is used to adjust the drilling fluid density and help determine casing points.

Drilling efficiencies

Mud logging companies have moved to include the efficient drilling of the well and its geologic aspects as part of their service. In deepwater operations, this has become a primary use of mud-logging services. Data monitoring provides the drilling department with information that will allow them to adjust (if necessary) the drilling parameters to ensure that the borehole is drilled in the most cost-effective manner.

Having a dedicated and equipped mud-logging cabin on location can help avoid costly trouble time. Should an event take place, continuous monitoring and recording of data allow for complete analysis, not only on a foot-by-foot basis, but also on a time basis as a last resort and ultimate backup, thereby shortening the learning curve.

Mud-logging operations do not stop when drilling ceases. The authors have found that most, more than 70%, of the time spent on a well is not directly involved in a bit being on bottom drilling. The "flat line" time is where most costs are incurred, especially in deepwater. Mud loggers are responsible for monitoring nearly every aspect during the course of the well, both for safety and evaluation requirements. Much of the information collected during the post-drilling activities is extremely useful in planning future wells.

Challenges

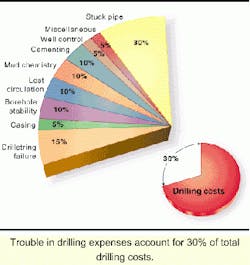

Trouble in drilling expenses account for 30% of total drilling costs.

The demands on the people on location have become more challenging. The push toward greater footage/hour/day and drilling equipment requiring fewer connections, surveys and trips result in fast and furious activity for the logger. For example, the authors have observed a well drilled more than 8,000 ft in one day. This required collecting samples for description and analysis at 30-foot intervals, requiring 267 samples per day (11 samples per hour).

Although unusual in scope, the above is not unusual in complexity. The lead hand on the job said, "over the past year and a half, the mudloggers here have become the data and information monitors/providers/managers on the rig. Many out here have come to rely heavily on us and there is pressure, both external and internal, to perform at a very high level. For me, this job is not so much a burden, as a challenge."

The interpretations have become more difficult with the introduction of newer drilling fluids. The use of more specialized drilling fluids causes two effects in logging operations:

- Exposure to the fluids with health, safety, and environmental concerns, requiring increased protective gear inventory

- Hydrocarbon and show evaluation has problems with polymer degradation, additive masking, and synthetic masking of formation fluids and gas.

Holes that would have been impossible to drill 20 years ago are now common-place, and the current demands for information from the mud-logging unit were not even thought of, much less possible to handle then. Today's mud logging unit should be capable of assisting both geology and drilling in making these nearly impossible wellbores possible.

As the gap between oil prices and finding costs narrows, there is a strong need to reduce expenditures through drilling optimization and trouble avoidance. The increasing concern for safety and for protection of the environment calls for even more effective project management and control. These multiple demands should be met by providing decision-makers with powerful, flexible tools to assist them.