William Furlow

Editor-in-Chief

Frank Hartley

Drilling/Production Editor

Open hole, wireline logs are an essential tool for evaluating subsurface hydro-carbon bearing strata and helping to reduce exploration risk. Open hole logg-ing data is used in selecting perforation intervals, determining net pay in a well, identi-fying in-fill locations in a development program, and optimizing stimulation design. However, acquiring this type of data can, in many instances, come with considerable costs and challenges.

Rig time, hole conditioning, wiper trips, expensive oil-based muds, and additional cycle time (added to the exploration process) all drive up the costs of this data. In addition, there are a number of operational risks involved. These include: sticking tools in the hole, losing nuclear sources, poor logging environments, deviated wells, and severe wash-outs.

null

All of these can dramatically impact the data acquisition, and thus the quality of interpretation. In some cases, an operator may have spent a substantial amount of time and money trying to get open hole log data, and in the end, have nothing to show for the effort. Not having the subsurface informa-tion needed for decision making greatly increases the risk of plugging and abandoning the well.

It is much easier and safer to acquire subsurface data from wireline tools in a cased hole environment. The smooth casing wall eliminates most of the risks associated with open hole logging, but it is more difficult to acquire the necessary data needed for making completion decisions through casing. Most cased hole log data is complicated to interpret and unfamiliar to most geoscientists. Engineers and geoscientists commonly deal in terms of porosity, resistivity, and saturation, which is not easily obtainable from cased hole logs using traditional methods

To overcome these limitations, Halliburton has developed a new artificial intelligence (AI) method for extracting open hole information from cased hole logs. Chi modeling, as it is called, uses cased hole pulsed neutron information to accurately reproduce the corresponding open hole response in the well for net pay determination and completion decisions.

Using a combination of genetic algorithms and sophisticated neural networks, Chi processing produces deep resistivity, compensated neutron porosity, bulk density, photoelectric, and sonic slowness logs from Halliburton's pulsed neutron tools (TMD-L and RMT Elite), giving engineers and geoscientists the information they need to make decisions and maximize produc-tion. Additionally, Chi processing reduces the operational risk of acquiring open hole logs, allows rigs to move off location much sooner, decreases overall cycle time for a project, and reduces costs.

Jack Wiener with Halliburton explains that these sophisticated AI techniques for processing Halliburton's pulsed neutron data actually "learn" the corresponding open hole response for any given subsurface geologic environment, including the reservoir's hydrocarbon potential. The data is first carefully pre-processed. Then it is entered into the genetic algorithm and neural network for statistical consistency and accuracy.

The data is then set as a baseline against the composite field set and run through the Chi processing technique. Chi processing then develops multiple generations of offspring of the pulsed neutron data creating lineages of "fit" variables, which are then fed into a cascaded network. The resulting open hole curves that come out of the program are then checked again against the field composite for statistical accuracy and delivered to the customer. Turn around time for this product is usually less than 24 hours.

The cased hole results are compared and corrected based on the original open hole logs of other wells in the field. This is a critical step in the process. Wiener said it is vital that all the data collected through this system be highly accurate because it will ultimately feed a 3D earth model.

With the teach-and-test feature of this program, it is also possible to combine accurate, but very weak, dated open hole and offset logging results with new, cased hole Chi-processed data to gather details about zones not tested originally. In some situations, these logs could be used to identify shallow gas plays that were bypassed in earlier drilling. Re-completing such a well could provide access to a new zone for a fraction of the cost of drilling a new well.

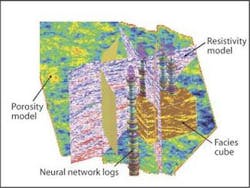

The Chi processing method is only the tip of the iceberg. The really exciting part of this process is that Chi modeling data can then be fed into the 3D earth-modeling environment for reservoir characterization studies, Wiener said. The 3D geocellular models of subsurface hydrocarbon reservoirs provide greater insight into hydrocarbon accumulations than possible with simple 2D maps and cross sections. Using advanced geostatistical and visualization techniques, Wiener said it is possible to better describe reservoir prop- erties such as porosity and permeability and image the subsurface more clearly. Reservoir volumes, compartmentalization, structural complexity, and over-pressured zones are analyzed in the 3D modeling program using the Chi processed data. The goal is to produce highly accurate petrophysical "volumes" to help operators with net-pay determination, enhanced well placements, improved economics, optimized frac design, and reservoir simulation studies.

Over the past year, Halliburton has pro-cessed more than 250 logs using Chi modeling in the Rocky Mountains, mid-continent US, and Gulf of Mexico. In many cases, this has led to reduced risks and savings in logging costs, rig time, and lost or stuck tools. Depending on the situation, Wiener said, an operator can save 25% to 80% on logging costs alone using Chi processing.