Floating production is the system of choice for all deepwater developments off West Africa to date. The absence of pipelines, the extent of the giant reservoirs and the mild metocean conditions all favor use of spread-moored floating production, storage, and offloading (FPSO) vessels.

For one of the two current projects, Nigeria's Bonga, Shell and its partners have a vessel at the heart of their scheme connected directly to subsea well clusters. On Kizomba A off Angola, the vessel will be linked to a surface wellhead tension leg platform (TLP). Both will represent the state of the art in large FPSO newbuildings, with storage capacity of 2 MMbbl or higher.

One party common to both projects is UK engineering group AMEC. It is managing design and fabrication of the Bonga topsides out of its yard in northeast England. Its role on Kizomba A is less hands-on, providing topsides engineering and project management support for the main FPSO contractor, Hyundai.

Bonga

Bonga is situated in Nigerian offshore prospecting license 212, 120 km southwest of Warri. The field lies in water depths of 950-1,150 meters and was the first discovery in the deep offshore Nigeria frontier. Shell operates the license on behalf of Nigerian National Petroleum Corp. (NNPC), in association with Esso, Agip, and TotalFinaElf.

Samsung in South Korea completed the Bonga FPSO hull in November.

According to a paper given by two Shell authors at the Offshore West Africa conference in Abuja last March, the Bonga reservoirs are turbidite systems. The sediments were deposited during major sea level lowstands where submarine fans were provided with coarse clastics. At other times, these areas were blanketed by fine-grain material.

Prior to the conference, four wells had been drilled, including the original discovery well from early 1996. Analysis at that point suggested 600 MMbbl of oil could be recovered from the four Bonga reservoirs under study, but water injection would be needed to maintain reservoir pressure, optimize sweep efficiency, and maximize ultimate recovery during field development.

Shell Deepwater Services in Houston and New Orleans reviewed various options for Bonga during 1997-98. Possible solutions ranged from established production systems (TLPs, semisubmersibles, and FPSOs) to untried concepts such as the mini-TLP and the multi-purpose barge. The partners concluded that the field's large areal extent - close to 60 sq km - would be best served by subsea well clusters drilled and completed from a mobile drilling unit. Production would then be processed on a large FPSO with a design life of over 20 years. The FPSO would be capable of handling 225,000 b/d of oil. This solution, they felt, would maximize recovery and the project value throughout the field life.

The approved design includes storage capacity of 2 MMbbl of stabilized crude, water injection of 300,000 b/d, produced water capacity of 100,000 b/d (upgradeable to 160,000 b/d) and gas export at a rate of 170 MMcf/d. The processed oil will be exported through three risers to an offloading buoy (SPM) 1,852 meters distant. According to a paper at presented at the 2001 Deep Offshore Technology conference by Coflexip Stena (one of the Bonga mooring installation contractors), these risers, each 2,238 meters long, will be installed in a single wave (W shape) configuration, which will be sustained through use of buoyancy modules. The buoy will be moored with taut polyester lines, the first such application off Nigeria. The mild, uni-directional environment in the Gulf of Guinea allows the vessel itself to be spread moored in a non-weathervaning mode.

Bonga's wells are to be batch drilled by a semisubmersible drilling rig and will be capable of producing up to 50,000 b/d. Due to the unconsolidated sands, open-hole gravel pack completions with pre-packed screens will be required for horizontal producers, with "frac-and-pack" for conventional producers. The completions must also guarantee stable production at a variety of water cuts and reservoir pressures. Water injection will be necessary from the outset, with artificial lift to be phased in later on, primarily through injecting lift gas at the riser base rather than downhole.

The subsea wells will be manifolded and connected to the FPSO through inter-field flowlines, risers, and control umbilicals, with provisions for adding further manifolds and risers during later development phases. Thirty-six development wells will be drilled, with 12 completed prior to first oil. Nine of the wells will be sidetrack/recompletions, limiting the number of subsea trees required to 27. These trees, supplied by ABB Vetco Gray, will be tied back into five manifolds, with 10-in. pipe-in-pipe steel prod-uction flowlines.

The 12-in. steel water injection flowlines and the 16-in. gas export pipeline will connect to a riser platform closer to the shore, where Bonga's gas will flow through a 32-in. pipeline to the Bonny liquefied natural gas (LNG) terminal. The flowlines and gas export line will be linked to the FPSO through steel catenary risers.

Topsides composition

The completed vessel will be 315 meters long, 58 meters wide, with a deadweight of 300,000 tons. It will operate in a water depth of 1,030 meters. AMEC's $438 million contract covers engineering design, procurement, fabrication, integration, and commissioning of the topside production facilities, which are being sourced from numerous locations worldwide.

Altogether, the 12 main topsides modules and associated pipe racks, cranes, and other miscellaneous items will weigh 17,000 tons. Of these, the heaviest will be the 1,950 ton power generation module comprising four 27 MW generators. This is being assembled at the AMEC yard at Wallsend, UK, along with the main pipe racks and the compressor for recovering low-pressure gas from the process separation modules.

Most remaining modules are the responsibility of Heerema, with which AMEC has an alliance for this project. Its yard at Hartlepool, a short way down the coast, is fabricating the process separation, flare scrubber, and crude fiscal metering units. Heerema's Zwijndrecht yard, inland from Rotterdam, is providing three sets of export gas compression facilities, the compressor control station, water processing/injection equipment and pipeline pig reception systems. Daewoo in Nigeria will supply the flare boom, sales gas metering system, and the laydown module, which will house chemical tanks - all to be shipped to Wallsend for integration.

AMEC's prior track record with FPSO topsides related to Shell UK Expro's Curlew and Anasuria vessels in the late 1990s. In both cases, the number of modules was double those on Bonga, but their total weight was two-thirds or more lower. Anasuria and Curlew had respective deadweight of 125,000 tons and 100,000 tons, compared with 300,000 tons on Bonga.

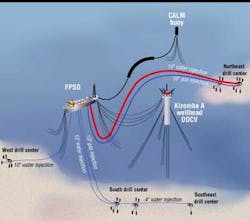

Kizomba Field development schematic.

According to Richard Jenkins, AMEC's Regional Manager-Africa, the Bonga hull should arrive in Wallsend this August, with topsides outfitting due to be completed in spring 2003. AMEC is also responsible for the subsequent tow-out to the field location. A short period of offshore hook-up and commissioning will then follow.

"The time between submitting our bid and getting the contract award took longer than we had envisaged," Jenkins says. "In the event, first oil will be produced 36 months after development approval. That's a challenging schedule for a project this size."

As might be expected, AMEC has had a team in South Korea liaising with project staff from Samsung and Korea. "But we've also made every effort to get Nigerian companies involved," he stresses. The three modules built by Daewoo in Warri are being designed by the Nigerian Engineering Technology Company (Netco), a subsidiary of NNPC, based in Lagos. Netco has also done some work on the Bonga topsides lighting scheme. "The flare tower turned out to be the most complex of all the topsides packages," Jenkins claims, "because of the movements of the structures, stresses, flare expansion, and the hot temperatures at the end of the tip."

AMEC has set up a small branch of its own in Nigeria, following its "local participation" model. It adopted a similar approach for recent offshore projects in the Philippines and Caspian. "Our idea is to match our core capabilities with the local companies' strengths. We bring to them understanding of technology, and also how to bring together complex projects."

Nine Netco engineers have been seconded to different countries working on all aspects of the Bonga FPSO. In the future, the company could work with AMEC on non-Nigerian projects, Jenkins says, as part of a plan to build a globally available network of skills that could be offered for any offshore project.

Kizomba

Sanction for the $3 billion Kizomba A project was announced by operator Esso Exploration Angola last August. Esso and partners BP, Agip, and Statoil are developing the Chocalho and Hungo discoveries, located in water depths of 3,300 to 4,200 ft, in Angola Block 15. There will be 59 development wells, comprising 33 producers and 26 injectors. The scheme involves a combination of a TLP, designed by ABB Lummus Global, with surface wellheads and a subsea production system tied back to a 2.2 MMbbl storage capacity FPSO. First oil is due out mid-2004.

Hyundai Heavy Industries is in this case assembling both the hull and the various topsides packages in Ulsan, South Korea. AMEC and its strategic alliance partner Fluor Daniel are jointly responsible for topsides engineering design, working from Houston. They are also providing project execution support to Hyundai's Kizomba A management team.

The FPSO will be 285 meters long, 63 meters wide and 32 meters high, with a deadweight of 300,000 tons, including 23,000 tons of topsides (much larger than on Bonga). It will be able to process 250,000 b/d of oil, and inject water at up to 525,000 b/d.

The topsides will include:

- High, intermediate, and low pressure separators

- Two trains of three-stage compressors

- A dehydration package designed to achieve 1 lb water per Mmcf of injection gas (via TEG regeneration package)

- Produced water treatment via hydrocyclones

- A seawater lift pump system

- A sulfate removal and water injection system

- Three main power generators incorporating waste heat removal units

- Utility modules including fresh water, nitrogen, chemical injection, methanol, diesel, and firewater systems.

There will also be accommodation for up to 100 personnel.

Saibos has the $230 million subsea engineering contract. This includes design and installation of:

- Flowlines between the FPSO and the TLP, and an umbilical to supply the TLP with electricity

- The crude offloading system, comprising a cantenary anchor leg mooring buoy and to rigid pipelines

- Subsea manifolds

- Risers and subsea injection lines.

The single line offset riser (SLOR) concept, developed jointly by Saibos and 2H Offshore, will be used for the water and gas injection risers. The concept involves connection of a single, vertical, rigid line to the FPSO via a short vertical jumper. The line is tensioned vertically by means of a conventional subsea float, and secured on the seabed through a flexible coupling. A pipe-in-pipe version of the SLOR could be used for the production flowlines, incorporating Vactub insulation technology from Saibos partner Bouygues Offshore. This is a rigid foam sealed in a plastic casing under a vacuum, providing sufficient insulation to deter wax/hydrate formation.

Daewoo is building the TLP hull in South Korea, and this will be transported to The Netherlands for mating with the topsides, under construction at Grootint. Heerema Marine Contractors and Stolt Offshore are fabricating the piles and tethers. The completed platform will be transported to Angola by Dockwise, in time for installation during fall 2003. The FPSO should sail six months later.

AMEC has bid major contracts with Hyun-dai before, and in this case was happy with the outcome. "There happened to be big advantages in being able to build the topsides and hull in one location," Jenkins says, due to the terms of the contract, and the fact that not many yards could handle both jobs simultaneously. Hyundai's satisfactory record on the Girassol hull and topsides also played a part in Esso's decision, he adds. "The lesson from Girassol was that you need a strong engineering design before embarking on such a large-scale FPSO.

"Our role is critical in this project. Our team for Kizomba A is based in Fluor Daniel's office in Houston, with roughly 300 people working on design/engineering." The topsides modules will vary in size and composition from those on Bonga, as the oil is also different. Produced gas will have to be re-injected for two years at least, with the Angolan LNG (gas-gathering) scheme unlikely to be implemented before 2006 at the earliest.

"The need for local involvement is as strong as in Nigeria," Jenkins says. "There isn't the same design engineering capability, but there is more local construction back-up in Angola than there is for Bonga. Items such as the helideck, boat landings, suction anchors, and offloading buoy will be built in Angolan yards.

"There is no AMEC workforce in Angola at present, although there is a Kizomba A project team office in Luanda, which Amec/Fluor Daniel are part of. We recognize that Angola offers a strong market for the technologies we're good at - large, complex projects. We're interested in bidding for BP's Block 18 developments and ChevronTexaco's Benguela/Belize in Block 14. We'd also like to continue our partnership with Fluor Daniel and Hyundai, possibly getting together with subsea groups as well."