Modular approach minimizes brownfield impact on live platforms

Editor's note: This story first appeared in the November-December 2022 issue of Offshore magazine. Click here to view the full issue.

By Abdullah J. Albahrani and Abdulmuti W. Al-Ruhaili * Saudi Aramco

Adopting a modular approach to new platform construction can pay dividends when operators contemplate brownfield activity. A modular approach minimizes the amount of new construction needed on the platform, after it has been placed in service. This kind of approach, if adopted early in the construction of platform, reduces the dangers inherent in live construction on an operational platform, and thus enhances efficiency and worker safety.

In the Marjan Gas-Oil Separation Plant 4 (GOSP-4) project — part of the ongoing Marjan Increment Mega-Program being executed by Saudi Aramco — the team explored the possibilities of minimizing the future brownfield works by implementing the modularization concept at a larger scale.

The Marjan GOSP-4 offshore facility is a new bridge-connected multiplatform facility. The GOSP-4 part of the Marjan Increment Program is considered the largest offshore facility to be built by Saudi Aramco. The purpose of the new offshore GOSP is to increase the production capacity of both oil and gas, meeting the corporate objectives to remain a reliable supplier of hydrocarbons.

Due to the nature of the reservoir, this is planned in a two-phase development program, where additional processing equipment, e.g., HPPTs, crude shipping pumps, and gas compressors will be required at a later stage in two of the six platforms: the gas compression platform (GCP) and the production platform (PP). Phase 1 of the project is faced with the challenge of designing the facility in terms of space, layout, tie-ins, etc., for seamless expansion and integration with the future Phase 2 project.

Fixed offshore platforms consist of two major parts: the jackets, which are the submerged steel structure of the platform functioned to lift the second part, the topsides. The structure hosting the processing equipment usually consists of multiple decks. In Marjan GOSP-4, both the GCP and PP topsides are four-level decks (main, mid, cellar, and sub-cellar). The production platform will house the high-pressure production traps (HPPTs), de-sander, crude shipping systems, and the associated utility systems while the gas compression platform will house the gas compression, cooling and sea water systems, and the associated auxiliary systems.

In the future Phase 2, there will be a requirement for a major expansion of these systems, including an additional separation, crude shipping, and gas compression trains. To put things in perspective, the space required for the expansion is 17 m x 62 m, which is equivalent to 22% of the current PP layout, and 30 m x 54 m, which is equivalent to 50% of the current GCP layout. This expansion will entail brownfield work at a live offshore hydrocarbon facility, which poses great technical, logistical, and safety risks in the construction phase. Reducing the brownfield scope and duration is the main challenge to be addressed.

Layout considerations

One solution to this challenge is to build the topsides with the structural space requirement for Phase 2, where it can be loaded and installed at once and leave the piping and equipment installation to be done later at the offshore facility. However, this approach has major disadvantages that can be summarized into three main points:

- Increased safety risks during future Phase 2 construction due to space constraint. Another aspect is the limited accessibility to install the large equipment at its location, which creates more complicated critical lifts over company assets, especially the equipment located at mid and cellar decks.

- Installation limitations to the current Phase 1 project due to the immense topsides. Phase 1 topsides are already massive and require a super X-class vessel for the float-over installation. The weights of the PP and GCP, without considering Phase 2 expansion, are 23,700 MT (metric tonnes) and 20,000 MT, respectively, while the estimated weight for Phase 2 expansion is 4,570 MT for PP and 6,060 MT for GCP. These additional weights will impose complexity to the installation methodology and type of vessels to be used.

- Escalated costs to Phase 2 project due to extended offshore works duration. The execution cost for offshore construction work is more expensive than similar scope done at onshore fabrication yards. In general, brownfield work often results in schedule delays and cost overruns. The logistical issues of having the required manpower is another cost adder, specifically on offshore projects. The total duration to execute the scope is longer due to limited access to manpower; a typical jackup barge can accommodate 100/250 workers, while contractors can deploy double this number at fabrication yards.

This option has been intensively studied for the GCP. The offshore work will require an extended facility shutdown for more than two months, which will interrupt the production. This shutdown will be required to complete the brownfield works, which include the installation of major equipment, ~600 line pipes, electrical, instrumentation, and safety systems.

Modular concept

Modular construction as defined by the Modular Building Institute is “a process in which a building is constructed off-site, under controlled plant conditions, using the same materials and designed to the same codes and standards as conventionally built facilities.” An alternative to the first option is to locate all the future required equipment at one side of the facility and only consider their requirements in the jacket design. This approach has been pursued with the purpose of simplifying offshore construction, reducing the cost significantly by shifting construction scope from offshore to onshore, and mitigating the risks associated with brownfield works.

On the GCP, the future module will have approximately 600 tie-ins that are required to be connected into the existing Phase 1 lines, which exceed 2,500 lines of various sizes for the various systems. With the modularization concept, all these tie-in connections are limited to the corresponding header connection in the current Phase 1 facility. This minimizes the quantity of offshore hook-up work.

To achieve optimum cost solution for offshore projects, the goal is to transfer as much work from offshore to onshore fabrication yards. In this case, the required 6,062 MT of fabrication for GCP, inclusive of major equipment, piping, structure, electrical, instrumentation, and safety systems, can be installed at the yard, thereby reducing the duration of the offshore installation campaign.

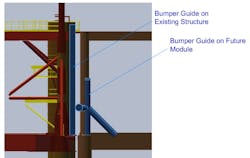

Considering the modular approach, the jacket will be designed with all the anticipated loads, thereby avoiding any required strengthening to the jacket structure at a later date – an expensive proposition. Future module installation challenges are addressed in the current design by providing bumpers on the jacket structure. The bumpers will mitigate the future installation risks that might lead to damage of the existing facilities. These additional loads from installation are addressed in the current design.

During Phase 2 design, guides are to be attached to the future modules to securely engage with the current facilities by bumpering against the existing structure for a smooth and correct position. The offshore welding work is minimally restricted to only the welding onto two columns, since all the piping headers are inside the perimeter of the modules.

One of the main challenges for Phase 2 will be the selection of the heavy lift vessel for installation of the future modules. The installation will require vessels with higher crane capacity, which comes with costs. However, the cost of mobilization of heavy lift vessels currently available will be much less compared to other methodologies, e.g., stick-built construction, a method selected for future expansions at other offshore plants.

Most importantly, going with the modular approach will reduce the safety hazards associated with brownfield works, as well as the shutdown and process interruption to the live facility. In general, placing the fabrication activities in the onshore yards yields better and more control measures than working offshore, when it comes to working from height, dropped objects, and lifting operations – which are the leading cause of accidents in offshore work.

Conclusion

Minimizing the construction activities on live hydrocarbon facilities can be achieved through the adoption of modular design. Modularization in general has more advantages than disadvantages. Adopting this approach in Marjan GOSP-4 will minimize production interruption, enhance safety, and reduce costs for any future expansion.

References

1. “What Is Modular Construction?” Modular Building Institute, 15 Aug. 2022, https://www.modular.org/what-is-modular-construction. Accessed 23 August 2022.

2. Visser, Folkert, and Rob Brouwer. “Executing Brownfield Projects,” paper presented at the Offshore Technology Conference-Asia, Kuala Lumpur, Malaysia, March 2014.

3. Hare, John and Michael Johnson. “Underlying Causes of Offshore Incidents,” Health & Safety Executive, 15 May 2009, https://www.hse.gov.uk/offshore/offshore-incidents.pdf. Accessed 23 August 2022.