Driven by the growing demand for alternate power sources and the need to reduce emissions, the offshore oil and gas industry has been deploying a new range of power supply solutions that are designed to increase operational efficiency and lower environmental footprint.

These new solutions fall in to four basic categories: offshore wind; floating power buoys; subsea charging stations; and new battery technologies. Power from shore – a long-established technology – is also gaining greater acceptance as a means of lowering emissions.

Some of the more notable examples of these new technologies are described below, with a focus on how they have been deployed offshore.

Offshore wind

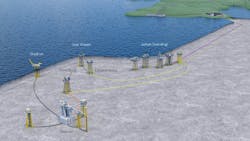

While most offshore wind energy projects seek to produce power for onshore markets, Equinor’s Hywind Tampen project seeks to produce power for existing oil and gas facilities. Hywind Tampen will be the world’s largest floating offshore wind farm, and the first designed specifically for powering oil and gas production platforms. The 11 wind turbines in the Norwegian North Sea, supported by moored concrete hulls, will provide 88 MW of power to five platforms at the Gullfaks and Snorre fields. They will represent 35% of the platforms’ annual power needs, with scope to increase the percentage during periods of higher winds. Construction of the substructures began last year, and the completed offshore wind park is due to transmit first electricity during the fall of 2022.

Norway’s government has been pushing increasingly for ‘cleaner’ power at the country’s major offshore field centers. To date this has been supplied directly from the shore through subsea power cables, but the Hywind Tampen wind park will be located much farther out – 140 km (87 mi) offshore – between the Gullfaks and Snorre field centers, in water depths of up to 300 m (984 ft).

Operator Equinor estimates that the electricity generated will meet around 35% of the two fields’ needs, and will replace power currently provided by the platforms’ gas turbines. Use of these turbines will be scaled back, reducing annual CO2 emissions from the two fields by around 200,000 metric tons (220,462 tons), and annual nitrogen-oxide emissions by 1,000 metric tons (1,102 tons).

Subsea power

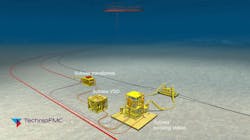

Subsea charging stations may provide another offshore power solution in the future. TechnipFMC has developed a subsea power distribution station that is said to simplify field installation, step-out wells and field expansions, and thereby support maximized reservoir recovery. The technology, which comprises a subsea transformer, subsea variable speed drive (VSD) and power transmission umbilical and connectors, received an Offshore Technology Conference Spotlight on New Technology Award in 2020. The compact, configurable design is said to be scalable for a wide range of boosting and processing applications and can operate in water depths up to 3,000 m (9,842 ft). Both the subsea transformer and VSD modules are based on technologies developed by the Brazilian electrical machines specialist WEG. TechnipFMC claims that the subsea power distribution station can cut subsea boosting costs for brownfield projects up to 60% by eliminating the need for topsides expansion modules.

Power buoys

Floating power buoys represent still another option for alternative offshore power sources. Maersk Supply Service A/S and Ørsted have partnered to test a prototype buoy that will act as both a safe mooring point and a charging station for offshore wind farm service vessels.

Maersk Supply Service has developed the prototype buoy while Ørsted will be responsible for its integration with the electrical grid at the offshore wind farm. The charging buoy will be tested in the second half of 2021, where it will supply overnight power to one of Ørsted’s service vessels.

Jonas Munch Agerskov, managing director for Offshore Renewables at Maersk Supply Service, said: “The charging buoy tackles a multitude of problems; lower emissions, offering a safe mooring point for vessels, better power efficiency and eliminating engine noise. This is also a solution that can be implemented on a global scale, and one that can be adapted as the maritime industry moves towards hybridization and electrification.”

Upon technical validation and commercial ramp up, the electrical charging buoy has short- to medium-term potential to reduce emissions for the maritime industry, according to the companies. This will happen through displacing tens of thousands of tons of fuel consumed every year in the wider maritime sector by enabling inactive vessels to turn engines off and replace energy consumption and charge batteries with renewable electricity. Within five years of global operation, Maersk Supply Service has the ambition to remove 5.5 million tons of CO2, additionally avoiding particulate matters such as NOx and SOx.

Meanwhile, New Jersey-based Ocean Power Technologies Inc. (OPT) has introduced the hybrid PowerBuoy, which it describes as “an easily deployable power and communications platform for any ocean environment.”

The buoy stores power for topsides and subsea payloads in onboard lithium iron phosphate batteries primarily charged via solar panels. A “clean burning,” silent 1-kW Stirling engine serves as a backup source of charging power, fueled by propane or biofuel (Generation 2) in commercially available 100-gallon tanks.

Power is generated independent of wave activity, which the company said makes it an ideal solution for powering through extreme weather and heavy seas or in calm, low wave environments, including near shore and inland bodies of water.

The new buoy is said to be applicable across many industries, including emergency and short-term power and communications support for maintenance, testing, and repair services. It can also be configured with marine surveillance solutions for security monitoring of offshore areas.

Data from the buoy is transmitted to shore-based command stations via communications networks, including WiFi, cellular, mesh and/or satellite systems, depending upon location. Data can also be integrated with satellite, terrestrial, and other data feeds to form a detailed surface and subsea view, the company said.

OPT has put the first hybrid PowerBuoy through an initial sea trial that included several tow configurations, roll, and pitch stability measurements, Stirling engine and solar power source operation and integration, and other tests in coastal New Jersey waters. It met or exceeded stringent engineering requirements, the company said.

OPT has also reported that its PB3 PowerBuoy had surpassed 600 days of continuous operation for Eni’s Phase 1 resident AUV project in the Adriatic Sea. Initially leased by Eni in 2018 for an 18-month mission to convert wave energy into electricity for powering underwater vehicles, the PB3 PowerBuoy lease was extended in March 2020 for an additional 18 months. To date, this system has produced more than 2.7 MWh since it was deployed.

Battery technology

A number of drilling rig contractors and vessel owners have been deploying new battery technologies as a means of cutting fuel costs, reducing emissions and increasing fuel flexibility. Hybrid power systems which feature battery energy storage systems are featuring prominently in those plans.

Maersk Drilling is converting two ultra-harsh environment jackups into hybrid, low-emission rigs. The company is performing the work on the Maersk Intrepid in co-operation with Equinor and on the Maersk Integrator with Aker BP. The upgrades involve running the rigs on hybrid power with low levels of nitrogen oxide (NOx) emissions, and adding data intelligence to further reduce energy consumption and CO2 emissions.

Maersk Drilling notes that energy use onboard a rig is characterized by high peak loads during certain operations. Through use of batteries for energy storage, power will be instantly available when needed. This means that fewer engines operating at a higher intensity can supply basic energy requirements, an arrangement said to be more efficient and with lower CO2 emissions. The drilling rig contractor is also employing energy emission efficiency software and selective catalytic reduction units to reduce NOx emissions as part of its larger emission reduction strategy.

Transocean has deployed what it claims is the world’s first hybrid energy storage system onboard a floating drilling unit. The system is now operational on the semisubmersible Transocean Spitsbergen, which is drilling at the Equinor-operated Snorre field offshore Norway. Transocean’s patented hybrid power technology, developed in partnership with Aspin Kemp and Associates, is said to reduce fuel consumption and increase a dynamically positioned (DP) rig’s station-keeping reliability by capturing energy generated during normal rig operations that would otherwise be wasted, and storing it in batteries. This energy is then used to power the rig’s thrusters. This operational and safety enhancement targets a 14% reduction in fuel use during normal operations, leading to a reduction in NOx and CO2 emissions. President and CEO Jeremy Thigpen said: “This first of its kind hybrid power upgrade will further enhance the reliability of our operations, while simultaneously reducing fuel consumption, operating costs, and our environmental footprint.”

In 2019, Northern Drilling’s West Mira became the first rig in operation to be awarded the DNV GL Battery (Power) class notation. The ultra-deepwater semisubmersible operates a hybrid power plant using lithium-ion batteries as spinning reserve in DP operations and to supply power during peak load times. Installation and testing of the energy storage system was completed with close cooperation between Seadrill/Northern Drilling, Siemens, Kongsberg Maritime, and DNV GL. “With the Battery (Power) class notation, we are helping our customers in the offshore industry take advantage of new technologies for safer, more energy-efficient and environmentally friendly operations,” said Geir Fuglerud, Director of Offshore Classification at DNV GL. “Hybrid and fully electric battery solutions have already been installed in almost 200 marine vessels globally. We are now seeing offshore rigs stepping up to take advantage of these energy storage systems, with several more rigs soon to follow West Mira.”

Siemens’ BlueVault lithium-ion battery technology, as deployed on the West Mira, consists of four converter-battery systems for a total maximum power of 6 MW. Siemens estimates that the energy storage solution will reduce the runtime of the rig’s on-platform diesel engines by 42%, cutting CO2 emissions by 15% and NOx emissions by 12%. The batteries will be charged from the rig’s diesel-electric generators and used for supplying power during peak load times.

The system will also serve as back-up to prevent blackout situations and provide power to the thrusters in the unlikely event of loss of all running machinery on affected switchboard segments, DNV GL said. “The integration of energy storage with the power supply and distribution system of a drilling rig represents an important step towards improving the environmental sustainability of the offshore oil and gas industry,” said Bjørn Einar Brath, Head of Offshore Solutions for Siemens. “Offshore rigs have highly variable power consumption for drilling and dynamic positioning. By incorporating energy storage, it is possible to reduce the runtime of diesel engines and also keep them operating on an optimized combustion level. This ultimately leads to lower emissions.”

In addition, they will serve as backup to prevent blackout situations and provide power to the thrusters in the unlikely event of loss of all running machinery.

Many offshore support vessel owners are also embracing hybrid power technology.

Wärtsilä is supplying hybrid propulsion systems to Eidesvik Offshore’s construction vessel Viking Neptun, CBO’s supply vessel CBO Flamengo, Atlantic Offshore’s supply vessels Ocean Star and Ocean Art, and Acta Marine’s DP-2 walk-to-work construction support vessel Acta Centaurus. Wärtsilä said its solution should deliver further benefits in the form of fuel cost savings, better environmental performance, and lower maintenance costs as the load on the engines should be more efficient and the running hours reduced.

Besides vessels and rigs, new battery solutions are also being deployed on production platforms as a means of enhancing reserve power. Two years ago, ABB Australia supplied Woodside Energy with a microgrid solution featuring a lithium-ion PowerStore Battery energy storage system on the Goodwyn A platform offshore Western Australia.

The installation was the first offshore application of such technology anywhere, Woodside claimed. The 1 MWh PowerStore Battery is designed to reduce the need for back-up capacity, or ‘spinning reserve,’ in Goodwyn A’s power generation system.

Elsewhere, efforts are under way to develop floating energy storage systems which can be used to provide alternate power to vessels or to supplement onshore power supplies. The Energy Market Authority (EMA) of Singapore and Keppel Offshore & Marine (Keppel O&M) have jointly awarded a research grant to pilot Singapore’s first floating energy storage system.

This project was awarded to a consortium led by Envision Digital International Pte Ltd. This is part of the $10-million partnership between EMA and Keppel O&M to develop energy solutions in the marine market, which was announced in April 2020.

The consortium also includes Mirai Electronics Pte. Ltd., Fuji Bridex Pte. Ltd., National University of Singapore, and Institute of Infocomm Research at the Agency for Science, Technology and Research. Keppel O&M will work with the consortium to deploy a 7.5 MW/7.5MWh lithium-ion battery ESS on its Floating Living Lab. Chris Ong, CEO of Keppel O&M, said: “Besides supporting Singapore’s energy needs, the developed solution will have multiple applications such as supporting areas with intermittent power supply, and rapid deployment to provide emergency power for places or remote islands affected by power disruptions. It can also be deployed on hybrid or fully electric vessels to significantly reduce carbon emissions.” The project is expected to be completed in 2023.

Power from shore

While the technology is not new, power from shore is becoming an increasingly attractive choice for many North Sea facilities, both existing and planned. Its attraction rests on replacing gas turbines, sited on offshore facilities, with greener or more efficient land-based power sources. Recently, Wintershall Dea converted its Mittelplate drilling and production island in the Schleswig-Holstein Wadden Zee National Park off northern Germany to run 100% on electricity from renewable energy. “We were able to stop generating electricity with a gas turbine and switch to green electricity from shore environment,” said the company’s chief technology officer Hugo Dijkgraaf.

“Hereby we save up to 36,000 metric tons [39,683 tons] of CO2 annually and significantly reduce our ecological footprint in this sensitive natural environment.”

Other operators are considering the option. Trondheim-based OKEA says that it is reviewing power from shore options for its Draugen platform complex in the Norwegian North Sea. The company is considering a tieback of the Hasselmus field to its Draugen platform complex that would begin operations within the next year. That field development plan includes a power from shore option for Draugen. OKEA hopes that its Draugen platform will serve as a hub in the Haltenbanken area.

Elsewhere, other power from shore plans are being developed. In the Utsira High region of the North Sea, Equinor and its license partners have agreed that the power-from-shore solution for Phase 2 of the Johan Sverdrup development will include additional capacity of 35 MW to meet the needs of the nearby Edvard Grieg, Gina Krog, and Ivar Aasen fields and others that might be developed in the future. The Sleipner field center and the Gudrun platform in the North Sea will also receive power from shore. Equinor estimates that partial electrification of Sleipner would cut the complex’s carbon dioxide emissions by more than 150,000 metric tons (165,347 tons) annually.

Meanwhile, Equinor has announced plans to modify the topsides on its Troll B and C platforms, in order to accommodate imports of power from shore. Geir Tungesvik, senior vice president for project development at Equinor, said: “The main driver in the electrification project is to reduce CO2 and NOx emissions from the Troll B and Troll C platforms by using electrical power from Kollsnes and replacing the existing gas-turbine driven electricity generators and gas compressors with electrical equipment. The selected concept for the electrification is full electrification of Troll C and partial electrification of Troll B with a possibility to fully electrify Troll B later.” Equinor is targeting CO2 reductions of 450,000 metric tons/yr (496,040 tons/yr).

The electrical system and power cable from shore will be designed to accommodate full electrification for both platforms.