By J.S. Mandke

Kellogg Brown & Root Inc.

Brian Smith

GD Engineering

Tim Ellisor

Marathon Oil Co.

Based on the experience with ETAP subsea pig launcher, a new subsea pig launcher for deep and ultra-deepwater applications has been developed.

Subsea fields with marginal reserves are generally produced through a tieback to a nearby host platform facility through single or dual flowlines. Associated flow assurance challenges limit the tieback distance in deep and ultra-deepwater.

In a typical deepwater subsea tieback, flowlines transport produced hydrocarbons from a subsea manifold, a template, or a wellhead to a nearby floating or fixed platform. The connection between the flowline and the platform top can be through an appropriate riser configuration.

Routine pigging operations

Flowlines characteristically require routine pigging operations to remove paraffin and organic deposits, liquid hold-up, scale, and other accumulations. The traditional approach is to use two flowlines with the round trip pigging operations performed from the host platform. In deepwater fields, the high capital expenditure and operating expenditure can adversely impact the overall project economics. Single-trip pigging offers an economic alternative to round-trip pigging, especially for deepwater and ultra-deepwater applications, where the cost of an additional flowline can be substantial.

ETAP Field

The offshore industry has developed several subsea pig launchers over the past 20 years. Most were used only during commissioning of the flowlines. The first subsea pig launcher used regularly during the flowline operation was installed in the North Sea in the ETAP Field.

The pig launcher barrel is installed on a six well manifold using a multi-bore hydraulic connector. Guide funnels and soft landing systems are used to aid guidelineless installation of the launcher.

The ETAP system has operated successfully for over two years. Although the pig launcher operated in shallow water, the experience has been beneficial in developing a new subsea pig launcher for ultra-deepwater application. The requirements for a deepwater launcher are different from the system designed for shallow water.

Deepwater pigging requirements

In ultra deepwater, the cost of offshore intervention to replenish the launcher with a new set of pigs can be high if the entire launcher barrel is brought to surface for recharging with new pigs. For this reason, the launcher should have a capacity to hold a large number of pigs so that an offshore intervention frequency of one or two times a year to replace the pigs is sufficient.

If the launcher barrel holds a large number of pigs, then it is possible that some of the pigs will stay in the barrel for as long as one to two years. The pigs should retain their integrity over this time. Ensuring this integrity requires that the fluid used in the launcher barrel be chemically compatible with the pig material. In general, pipe-cleaning pigs are made from polyurethane material, known to be incompatible with methanol or produced hydrocarbons, which have been used in the past to push pigs out of the subsea launcher barrel.

Installation vessel requirement

Installing the pig launcher barrel in ultra deepwater may require a large capacity dynamically positioned (DP) multi-service vessel (MSV). However, in deepwater applications, the subsea pig launcher (SPL) installation should be without guideline and assisted by a remotely operated vehicle (ROV). The replacement of the pigs can be from a DP diving support vessel (DSV) or MSV. To minimize offshore intervention cost, operations such as replacement of pigs should be done efficiently using economically priced vessels, such as DSVs. The pigs can be launched remotely from the host platform when needed.

The successful experience gained from the development of ETAP subsea pig launcher has been used in the development of the new pig launcher with a closure at the top and other appurtenances such as the supporting frame, guide funnels, etc.

Several SPL operations are performed under the risk of releasing stored fluids into the sea. This includes installation and retrieval of the launcher barrel from the seabed to surface, as well as the operations to reload pigs into the launcher. The SPL must satisfy the requirement of zero release of hydrocarbon into the sea at all times.

Ultra-deepwater SPL

Based on the experience at ETAP, Kellogg Brown & Root and GD Engineering, with the support of Marathon Oil Co., developed a new SPL for deepwater and ultra-deepwater applications. The new pig launcher satisfies the principal requirements for deepwater application, including the following features:

- 10,000-ft water depth

- 10,000-psi design pressure

- 6-in. to 16-in. flowline/header

- Capacity to hold 10 to 12 cleaning pigs

- Launcher barrel to be left on seabed

- Pig reloading with ROV

- Remote launching of pigs

- Zero release of hydrocarbons.

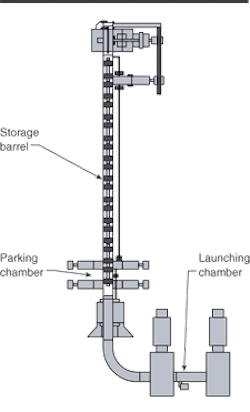

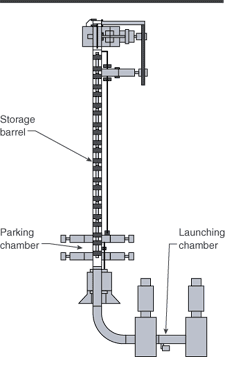

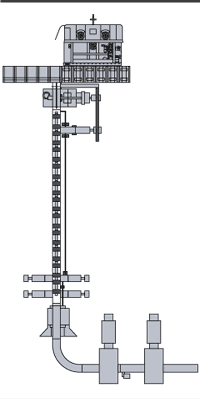

Storage barrel

The inside diameter of the storage barrel is slightly larger than the pig's outside diameter to allow easy movement of pigs. The pigs are stacked vertically inside the barrel. The last pig fits the inside diameter of the storage barrel to provide a seal and is referred to as the "piston pig." Pressurized hydraulic fluid behind the piston pig pushes the pigs through the barrel. A remotely operated valve controls flow of hydraulic fluid.

Parking chamber

A "pig parking chamber" below the barrel holds a pig temporarily before it is launched. The chamber has two remotely operated pig stops. Opening the top stop allows the foremost pig to move into the parking chamber. A kicker line connected to the chamber with a remotely operated valve allows hydraulic fluid to be pumped behind the parked pig.

Launching chamber

Releasing the lower pig stop and pumping hydraulic fluid into the parking chamber moves the pig into the "pig launching chamber." The launching chamber has an isolation valve on either side that isolates it from the manifold production header and flowline on one side and the parking chamber on the other.

A kicker line connected to the launching chamber via a remotely operated valve introduces production fluid behind the pig inside the launching chamber. Opening the isolation valve between the header and the launching chamber allows the fluid to push the pig from the launching chamber to the production header.

Once the pig leaves the production header and moves into the flowline, the isolation valve is closed. The launching chamber is flushed with methanol and then with hydraulic fluid to clean residual hydrocarbons from the chamber. Flushing fluids are allowed to flow into the production header via the crossover flushing line between the launching chamber and the header.

Magnetic sensor

After all pigs are launched, the piston pig is also launched. A magnetic sensor on the launcher barrel indicates to the host facility that the pigs need to be replaced. A gate valve or a high-pressure closure at the top of the barrel can be used instead of the gate valve at the barrel top. The ROV opens the valve or the closure at the top of the barrel to load a new set of pigs into the barrel. A launcher barrel at the bottom is connected to piping on the manifold by a multi-bore connector.

Separating launching from storage

By separating launching from storage, the new system allows the pigs to be stored inside the barrel in hydraulic fluid, which does not degrade the pigs. Use of production fluid to push pigs into the production header ensures that sufficient fluid volume is available.

The successful experience gained from the development of ETAP subsea pig launcher has been used in the development of the new pig launcher with a closure at the top and other appurtenances such as the supporting frame, guide funnels, etc.

The hydraulic fluid used for pushing pigs can be similar to the control fluid conventionally used in subsea systems. It is heavier than seawater, environmentally acceptable for release into the sea, and chemically non-reactive with standard polyurethane material used in pipe cleaning pigs.

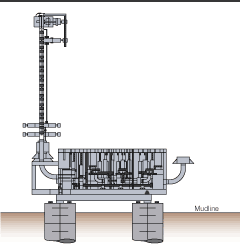

Installation of the launcher

The pig launcher barrel is installed on the manifold using a multi-bore hydraulic connector. Guide funnels and soft landing systems allow installation of the launcher without guidelines. An ROV is used to make the hydraulic connector and hook up flying leads between the launcher barrel and the control pod on the manifold.

To flush seawater from the launcher barrel, hydraulic fluid is introduced at the lowest point on the pig launcher, upstream of the launching chamber. The hydraulic fluid rises inside the barrel through the clearance around the pigs. A one-dimensional bypass on the piston pig allows the hydraulic fluid to pass trough. The displaced seawater is vented by opening drain valves. An ROV can monitor the vent port to check filling of the barrel with hydraulic fluid.

Reloading design/operation

A special pig reloading tool was designed to be attached to the underside of any workclass ROV. The re-loader carries the required number of pigs in open canisters on two sliding trays that can be activated hydraulically by ROV.

In a typical pig reloading operation, an ROV with loaded racks will be lowered to a subsea pig launcher and will attach to a specially designed platform at the top of the barrel. One rack of the pig reloader tooling will be extended over the barrel. As the rack extends, the pigs will fall into the barrel. The ROV manipulator arm or a special push rod can assist the pig loading. The piston pig will be the last to be loaded.

Summary

The experience from the development of ETAP was used to develop the pig launcher for ultra deepwater. The system uses hydraulic fluid for pig storage to ensure the integrity of the polyurethane pigs until they are launched. Use of production fluids in the launching chamber assures adequate fluid supply to push the pig in to the flowline. The key features of the new system are:

- Based on proven technology

- Positive control over pig displacement

- Use of conventional polyurethane pigs

- No degradation of pigs during long-term storage in launcher barrel

- Remote launching of pigs

- Pig replenishment with ROV operated from a DP RSV

- Environmentally "green" system.

New subea pig launchers are expected to help reduce the cost of long distance tieback of ultra-deepwater marginal fields.

Acknowledgement

The authors wish to acknowledge the support provided by the management of Kellogg Brown & Root, GD Engi-neering, and Marathon Oil Co. during the development of the pig launcher.