Optical fibers present opportunities and challenges for geophysical applications

Dr. Saeed Rehman

Fibertronix AB

Dr. Alexis Mendez

MCH Engineering LLC

Monitoring oil and gas reservoirs using large-scale, high-fidelity, fiber-optics sensor systems can provide timely, predictive information on reservoir performance. A key enabling technology is specialty optical fibers. However, the demands of higher operating temperatures and measurement of new physical parameters such as sound and vibration require a new generation of customized, specialty optical fiber designs.

The oil and gas industry has unique instrumentation requirements and monitoring needs, usually driven by the harshness of the operating environment coupled with the difficulty of mapping a reservoir over its life. Typically, operators have little information about a well's spatial or temporal behavior during production. Measurement of hydrocarbon flow at various critical locations in a reservoir would provide important information about reservoir architecture, geometrical dimensions, zonal performance and well-to-well interactions, and further contribute to reservoir optimization and reserves recovery. Monitoring downhole activity can provide good information in and around the wellbore as well as across the reservoir. Thus, a detailed mapping of the hydrocarbon behavior can provide a meaningful indication of how the reservoir is overburden under the influence of production and secondary recovery phases.

Furthermore, new trends for offshore enhanced oil recovery, harsher downhole operating conditions, horizontal wells, and the prevalence of more technically challenging and complicated reservoir projects around the world all drive the demand for permanent passive reservoir monitoring solutions. For example, real-time monitoring of temperature and pressure in oil wells is important to manage steam floods in heavy oil reservoirs, detect inflows in horizontal wells, and optimize the performance of a reservoir. It also offers important data for better, faster reservoir characterization. It will also improve forecasting of reservoir capability, thereby helping optimize the economic recovery of reserves.

Optical fiber sensors

Over the past decade, optical fiber sensors have become accepted within the oil industry due to their reliability, flexibility, low operating cost, and the benefits of their multi-point and distributed sensing capabilities. Initial applications focus on downhole, single-point bottomhole temperature and pressure sensing, as well as distributed temperature and strain reservoir sensing. Work is also under way to commercialize fiber optic seismic and acoustic sensing arrays—both offshore and onshore—for oil and gas exploration, pipeline surveillance, geophysical monitoring, and other uses.

Fiber optic sensors are used commonly in the acquisition of real-time data on a variety of oil well parameters such as temperature, strain, pressure, sand detection, vibration, and acoustic signals, facilitating optimization of a reservoir through its lifecycle.

Because they are interrogated by light, fiber optic sensors require no electricity. Thus, the size and weight of fiber-optic system usually can be tailored to the transport and installation program. Furthermore, due to their dielectric nature and no need for associated electronics downhole, they offer increased reliability by avoiding derating of active electronic components or materials degradation. Optical fiber based systems offer advantages beyond reliability. They have enormous capacity in terms of numbers of sensors, sampling frequencies, and data rates to enable very large-scale sensing systems.

Harsh environments

Depending on application and environment, optical fibers need to be coated for both mechanical and chemical protection. They also rely on the appropriate materials formulation and waveguide design to ensure reliable optical light guiding and resistance against possible hydrogen darkening. In general, the two main problems that can develop over the service lifetime of optical fibers whether subsea or downhole are:

- Increased optical attenuation from hydrogen-induced losses (hydrogen darkening)

- Decreased mechanical strength due to moisture corrosion and chemical attack.

Free gaseous hydrogen diffuses through conventional fiber coatings into silica-based optical fibers and produce optical light absorption in the infrared. This is commonly referred to as "hydrogen-induced loss" or "hydrogen darkening." Recent enhancements in specialty fibers—such as hydrogen-resistant, pure silica glass compositions (PSC) and improved high temperature coatings make possible the reliable operation of fiber systems in geophysical applications and have accelerated their acceptance for and deployment in oil reservoir performance monitoring.

A reliable and properly designed fiber sensing system relies on the appropriate specialty optical fiber combined with a suitable protective cable that affords the best long-term, optical, and mechanical reliability and durability by providing immunity against the external environmental effects, while maximizing the sensitivity and selectivity to the physical parameters of interest.

Given some of the ongoing trends – namely, higher operating temperatures and measurement of new physical parameters such as sound and vibration – new demands are being put on optical fiber sensors which will require a new generation of customized, specialty optical fiber designs with enhanced coatings – both for protection and increased sensitivity.

New sensing applications

Fiber sensing technology was introduced in the oil and gas industry as a replacement to the legacy electronic temperature and pressure gauges, as well as a tool to monitor non-conventional reservoirs and enhanced recovery in wells through distributed temperature sensing (DTS). Now, given that the technology has been field-proven, it is ready to be applied in more advanced and complicated sensing applications like high-temperature geothermal wells, distributed acoustic sensing (DAS), distributed pressure sensing (DPS), and more. These new applications are driven by the quest to detect the smallest possible changes in reservoir behavior, fluid content, pressure, and geomechanics is always a first priority for a reservoir engineer. It is beneficial for an engineer to monitor the reservoirs passively, to detect seismic events generated as the reservoir "creaks and groans" while it produces.

Such new applications also present new challenges to specialty fiber manufacturers in terms of new waveguide designs and fiber coatings to withstand increased operating temperature range (>300°C), and be capable of detecting acoustic signal and/or pressure along its entire length. Such challenges will drive the development of the technology and lead to new products and new markets in the years to come

Distributed acoustic sensing

Distributed acoustic sensing (DAS), based on optical fiber sensing, is a novel technology that allows the detection, discrimination, and location of acoustic events on a specialty optical fiber over several kilometres. Using a combination of the measurement of backscattered light and advanced signal processing, the DAS interrogator segregates the fiber into an array of individual "microphones." Using signal processing techniques and real-time backscattered light, the engineer can detect and identify a specific leak signature and eliminate unwanted events while highlighting useful acoustic components pertaining specifically to the leak.

Distributed optical fiber acoustic sensors are proven in submarine sonar systems. The optical fiber can be packaged in such a way that makes it sensitive to acoustic disturbances along its entire length. Different DAS systems are available but they are still in its early stage and need to be proved sufficiently reliable and sensitive to detect and monitor these in-well acoustic activities. The main challenge for these fiber sensors is to identify and differentiate between noise and actual acoustic event.

One exciting DAS application is in hydraulic fracturing of tight sand and shale. The cost of hydraulic fracture stimulation versus the production benefit is crucial in tight sand and shale gas developments. Acoustic event detection can provide 4D geophysical data and completion infrastructure monitoring, which can provide crucial data. This would provide an excellent view of reservoir depletion as well as permit production optimization. It is anticipated that engineers will be able to locate leaks with confidence to reduce operating cost by reducing the number of failed interventions. The need for experienced highly trained log analysts also will be reduced.

Distributed pressure sensing

Liquid hydrocarbons have to move from their reservoirs to remote plants for processing. Pipeline safety and reliability, as well as flow assurance are the main drivers for the development of new, on-line, monitoring techniques to detect and localize wax and hydrate build-ups and other blockages in oil pipelines. Historically, DTS systems have been used to indirectly detect and locate an internal blockage (or leak, for that matter) from the localized temperature change produced. Similarly, a distributed pressure system will be more effective and provide more direct information about flow characteristics and flow assurance.

Different fiber optic systems are in development which claim to measure distributed pressure along the length of optical fiber cable. Three main techniques, interferometic, polarimetric, and Brillouin scattering, are used to measure the pressure. In interferometrics, vibration is tracked along the length of the fiber. In polarimetrics, the change in the birefringence due the shape or deformation of the fiber, is measured along the length of the fiber. The third technique is based on the conversion of hydrostatic pressure acting along a specially coated optical fiber, into a distributed mechanical strain. Measurements of distributed pressure can be thus inferred by converting the applied hydrostatic pressure into distributed mechanical strain acting on the fiber, and measuring the strain changes by the Brillouin scattering frequency shifts they experience.

Seismic measurement

In petroleum exploration, it is customary to perform acoustic surveys using ships that drag strings with arrays of piezoelectric transducers that pick up the reflected wave vibrations produced by an acoustic pulse source. A multitude of reflected pulses provides information on the density and distribution or rock and hydrocarbons across the various layers of a formation to help locate new reservoirs. Similarly, periodic surveys on a producing reservoir can help assess the formation's properties over the life of the well. However, these electronic systems are prone to failure due to electric shorts, water leaks, and salt corrosion. Hence, more reliable seismic sensing systems based on optical fiber sensors have been proposed.

An example of a deepwater fiber optic seismic system that is completely passive (no electronics on the wet side), relying exclusively on the interrogation of light signals to measure vibrations and acoustic signals, is OptoSeis developed by PGS. This seismic system is of the 4D4C type, meaning that it has three fiber optic accelerometers (one for each orthogonal axis-x, y, and z) and one hydrophone, to detect underwater acoustic signals. These fiber optic sensors are of the Michelson interferometric type and are housed in a special protective pad. The system is designed for permanent installation as an ocean bottom cable (OBC) array. Subsea fiber optic cables are laid on the bottom of the ocean in a grid pattern to monitor underwater oil well activity over a large surface area, with sensor pads located every 50 m (164 ft) along the cable which is trenched into the seafloor to a depth of zero to 2 m (6½ ft) — allowing for continuous seismic monitoring in time, hence the 4D part —and over the service lifetime of the reservoir to provide life-of-field-seismic (LoFS) monitoring.

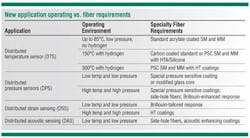

The requirements imposed by these new applications have resulted in the evolution of a new subset of custom-tailored optical fibers commonly known as "specialty fibers." There are three fundamental aspects that one can manipulate to develop a specialty fiber: glass composition, waveguide design, and coatings. The table summarizes the envisioned specialty fibers needed to address these new generation fiber sensing applications.

Conclusions

The adoption of optical fibers and fiber-optic based sensors continues to progress in the oil and gas industry, as well as other harsh environment applications. However, as the applications evolve, so do the technical challenges which demand improvements in performance and reliability. This drives the development of enhanced fibers with coatings that can withstand high temperatures and pressure, as well as those tailored to provide adequate temperature, strain, pressure, and/or acoustic sensitivity.

Offshore Articles Archives

View Oil and Gas Articles on PennEnergy.com