Jon Ruszka, John Fabian, Gavin Lindsay - Inteq

Extended Reach Drilling (ERD) is increasingly being used to intersect targets distant from the surface location or areas of the reservoir that are otherwise difficult to access. While ERD wells are demanding to drill, complete, and service, they deliver benefits in terms of reserves replacement and environmental protection, such as:

- Lowering environmental impact by consolidating surface facilities in selected areas

- Reducing capital expenditure in offshore fields through lower platform count and subsea flowlines

- Allowing access to offshore reserves from land

- Improving productivity and field recovery by placing longer lateral holes in the reservoir

- Increasing recovery via access to otherwise stranded reserves.

Continuous advancement in drilling engineering, directional drilling, and logging-while-drilling (LWD) technology coupled with increasing experience is allowing the ERD envelope to be challenged on multiple fronts. Today, ERD wells can be drilled faster to greater depth, can intersect the reservoir more accurately, involve lower risk, and can be confidently executed with more complex trajectories than those drilled just a few years ago. As a result, ERD wells are more cost-effective in a wider range of applications than ever before.

New technology addresses challenges

Since their introduction over 10 years ago, rotary steerable systems (RSS) have been continuously improved to provide more precise steering, higher reliability, and a broader operating range. The recent integration of drilling motor technology within the RSS can extend the reach of ERD wells past prior limits, simultaneously improving drilling performance.

Wireline logging is high risk and expensive to perform in ERD wells. Today, a wide range of LWD technology is available to describe the subsurface structures, which allow wireline logging to be eliminated. It is the application of these LWD technologies to real-time wellbore stability monitoring, however, that provides significant value in extending the boundaries and lowering the operational risk in ERD wells.

Advanced drilling dynamics measurements detect dysfunctions associated with rugose and over-gauge hole, but additional information is normally required to ascertain the actual instability mechanism. Real-time LWD image data (gamma, density, and/or electrical images) assist in confirming the mechanism. These image logs are used primarily in three ways to aid wellbore stability maintenance. Logs are used to interpret structures and sediments and to identify geomechanical features. By interpreting image data in real time, the wellbore geomechanical model can be updated, and the correct changes can be made to drilling parameters to increase wellbore stability when required. A high-resolution electrical imaging LWD log can show clearly the drilling induced fractures, whereas in a wireline log, the fractures are not visible. The images also allow correlation of stratigraphic position and identification of fault compartments, further enhancing the geological model and adding sub-seismic detail. Formation pressure testing while drilling is used to update the pore-pressure model, again allowing correct actions to be taken in real time to increase wellbore integrity when required.

Advanced measurement systems

Advanced diagnostic dynamics measurement systems monitor the downhole drilling environment for parameter optimization, enhancing bottomhole assembly (BHA) reliability. These systems also provide continuous real-time measurement of BHA bending moment. This unique measurement has proven invaluable to closely monitor the creation of formation induced borehole irregularities in some ERD wells. Unless these irregularities are identified and remedied, they can jeopardize successful drilling to TD. This measurement also has proven useful in providing a continuous real-time indicator of steering control. ERD wells with very complex trajectories can be maintained on plan to exploit otherwise impossible to reach reserves through the use of advanced measurement systems.

Mission critical

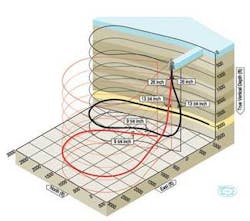

ERD is helping to set new standards. An example of this is a new world record in ERD that was set in April 2007, taking a well to 11,282 m (37,016 ft) measured depth. The well attained a number of notable successes, including precise positioning of the horizontal drain within a ±50 cm (19.7 in.) TVD target window and being drilled in 61 days, more than 15 days ahead of schedule and below expected cost with no safety or environmental incidents.

The industry has continuously advanced directional drilling, formation evaluation LWD, and application engineering competency to test and extend technical boundaries. As a result, ERD wells are becoming a lower risk, more cost-effective method to aid reserves replacement and can be used to reduce overall environmental impact.

ERD has been proven to increase reserves replacement and enhance environmental protection. It is possible that this technology will become more common in many locations around the world.