Dril-Quip’s DXe wellhead connector and BigBore IIe wellhead system have been selected by the Offshore Technology Conference (OTC) as winners of the Spotlight on New Technology awards for 2017. This award recognizes new technologies that are on the forefront of innovation in offshore exploration and production.

e provides the ability to reduce the number of casing strings by increasing loads and pressure capacities of the casing hangers and associated installation tools. Both technologies were awarded OTC Spotlight awards. ">

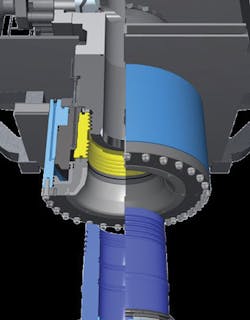

The DXewellhead connector is a blowout preventer (BOP)/tree/tieback connector that is suitable for high-pressure/high-temperature (HP/HT) service in severe bending and high fatigue environments. A highly engineered locking wellhead profile and self-aligning gasket design allows for increased structural bending capacity. The connector’s high fatigue-resistance provides extended service life. The technology of this critical connection is validated to the latest editions of API 16A (4th Edition) PR2 classification, and the recently issued API 17TR7 requirements. Based on full-scale physical testing, Dril-Quip says the connector has demonstrated that it delivers reliable performance and longer service life. Deployed at the base of a subsea BOP, the wellhead connector provides the only barrier between the well bore and the environment.

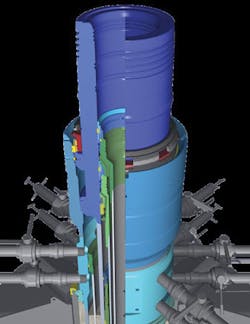

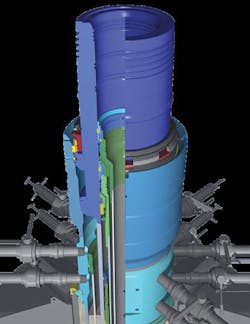

The BigBore IIeis a fully qualified wellhead system consisting of a DXe connection top locking profile, an integral 2 million-lb high-capacity hanger lockdown annular seal assembly, extended fatigue life, and what Dril-Quip says is the industry’s highest capacity running tools. The system’s hanger and seal assembly eliminates the need for secondary lockdown devices during drilling and production phases and reduces rig time by eliminating trips into the well for installation and retrieval of such devices. This reduces associated installation risks and HSE exposure. The BigBore IIeprovides the ability to reduce the number of casing strings by increasing loads and pressure capacities of the casing hangers and associated installation tools. Wellhead component designs have been verified and validated to AsPI 17D and API 6A PR2 Group 4 industry standards. Additional dynamic seal endurance testing has also been performed, exceeding industry specs, the company said.

Technologies awarded must be original and groundbreaking technology that is less than two years old, be proven through full scale application or prototype testing, demonstrate broad interest across the industry, and provide significant benefit over existing technologies. Representatives from the OTC board and program committee evaluate papers to determine which technologies will receive the award.

Dril-Quip will display a full scale model of the BigBore IIehigh pressure wellhead at its 2017 OTC booth #3775.