Single-run in-line pipeline inspection on an unprecedented scale

Dr. Stephan Brockhaus

Dr. Hubert Lindner

ROSEN Technology & Research Center

Tom Steinvoorte

ROSEN Europe

Holger Hennerkes

ROSEN

Dr. Ljiljana Djapic Oosterkamp

Statoil

An in-line inspection run of the world's longest subsea natural gas pipeline was completed successfully in the last half of this past year. A customized inspection tool overcame the challenges posed by the length, multi-diameter design, high wall thickness, high pressure and high gas velocity of Langeled Gas Pipeline. A RoCorr•MFL/SIC simultaneously measured internal corrosion and defect identification.

SIC measurement provides accurate depth sizing of shallow internal corrosion while simultaneously assisting MFL to identify defect depth size through its high lateral resolution of defect surface measurement. The RoCorr•MFL/SIC proved to be an effective and reliable tool to monitor corrosion growth rates. In general, the tool's combination of these complementary corrosion measurement methods gave Statoil high sensitivity for early feature detection, a high POI for internal/non-internal feature discrimination, accurate sizing capabilities, and high effectiveness in heavy-wall pipeline inspection.

ROSEN was chosen by Statoil to carry out this challenging project. The world's longest subsea gas pipeline, the 1,173-km (729-mi) long Langeled Pipeline connecting Nyhamna, Norway, to Easington, UK, was to be examined in a single in-line inspection (ILI) run. Langeled is designed to carry more than 70 MMcm/d (2.47 tcf/d) of dry gas to supply the equivalent of more than 20% of the United Kingdom's gas needs. The pipeline had never before been inspected in a single ILI run.

Design, operating challengesThe planned inspection was challenging not merely because of the pipeline's length but also because of its challenging design and operating conditions. Langeled is a multi-diameter pipeline with high wall thickness. For the first 632 km (391 mi) (up to some kilometers past the Sleipner platform), the pipeline diameter is 42 in. (106.7 cm) before increasing to 44 in. (111.7 cm) for the remaining 541 km (336 mi). Similarly, the pipeline's wall thickness varies from 29.1 mm (1.15 in) to 62 mm (2.4 in) in the 42-in. section and from 23.3 mm to 50.6 mm in the 44-in. section.

Although constant internal diameters are given in the specifications, the intermediate subsea installations (valves and tees) in the vicinity of Sleipner restrict tool passage. The ID is 1,016 mm (40 in.) in the 42-in. section and 1,066 mm (42 in.) in the 44-in. section. The minimum bend radius is 5D. Langeled Gas Pipeline is coated with epoxy on the inside, and asphalt and concrete on the outside. The pipeline's operating conditions complicated the inspection further.

Langeled has high product flow velocity and pressure. Operated at design capacities, the gas velocity increases over the pipeline length from 4 m/s to 9.5 m/s, with associated gas pressures of 220 bar (22 MPa) at Nyhamna and down to 75 bar (7.5 MPa) at Easington. Corresponding gas densities vary between approximately 61 kg/cu m (3.8 lb/cu ft) and 185 kg/cu m (11.5 lb/cu ft).

Combined technologiesStatoil and ROSEN considered which technologies would be most suitable for the planned baseline survey. They agreed to use ROSEN's RoCorr•MFL/SIC. This in-line inspection tool combines the two complementary corrosion measurement methods Magnetic Flux Leakage (MFL) and Shallow Internal Corrosion (SIC) with high-resolution geometry inspection. MFL, which measures relative wall loss, determines the geometry of metal loss in pipelines. SIC is an Eddy Current (EC) technology enabling absolute geometric measurements of internal corrosion defects.

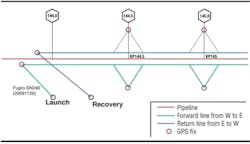

Route of Langeled pipeline, the longest subsea gas pipeline in the world.

The combination generates an approximation of corrosion growth providing therewith an effective tool for monitoring the degradation process. Since the technologies are complementary, the simultaneous application of MFL and SIC ensures a high Probability of Identification (POI) for internal and non-internal discrimination, notably accuracy in depths, length, and width sizing of internal corrosion defects. When inspecting heavy- wall pipelines in particular, SIC provides precise depth sizing of shallow internal corrosion (detection threshold ≥ 1 mm) while also assisting MFL defect identification and depth sizing due to its high lateral resolution in defect surface measurement permitting better distinction of individual pits in dense clusters.

Moreover, the simultaneous use of both corrosion measurement methods gives such high sensitivity that the combination not only makes high-accuracy measurement of defects but also enables early feature detection. High-resolution geometry measurement is provided by combining EC technology touchless deformation measurement with systematic monitoring by the mechanical caliper arms. Full coverage of the internal pipeline wall is by means of two inspection planes with a total of 108 caliper arms plus the associated SIC contour-following proximity sensors.

The multi-diameter challengeBefore the specially designed RoCorr•MFL/SIC tool was launched, it was necessary to ensure that it could transit all of Langeled.

To do this, a customized gauging tool was sent through the Langeled Pipeline first. With both a gauge and a bend plate, the tool was adapted to confirm the bend sizes and ID of the pipeline.

To overcome challenge from the high gas velocities in Langeled and to compensate for tool accelerations due to friction changes, the combo tool was equipped with a Speed Control Unit (SCU). The SCU enables the inspection run to be conducted at a pre-programmed target tool speed by controlling gas bypass to manage tool velocity.

In controlling the bypass flow, different factors must be considered, since not only the tool design (e.g. bypass area, differential pressure) determines the capacity of the SCU, but also pipeline characteristics such as wall thickness, changes in diameter, coating type, and gas density. A high tool differential pressure and a large bypass area enhance the performance of the SCU, but high gas densities such as in Langeled do the opposite.

To prevent the front segment of the combo tool from being pushed through the pipeline by the trailing unit, the bypass area on the rear segment must be larger. Despite this large bypass area, the rear segment still must accommodate components (electronics, batteries, storage, etc.). The specially designed RoCorr•MFL/SIC in-line inspection tool met this challenge because its flow circulates around and through parts of the tender's tool body before diversion through the tool body at the front segment and final release through the SCU.

Flow simulations indicate the combination of high bypass velocities and high gas density increase loads on the measuring unit of the rear segment (80 – 90 kg), so the flow circulating around the tender must be guided. Short caliper arms combined with notches and holes strategically placed in the cups, and specially designed lamella fins between the rear cup and the measurement unit permits partial diversion of the flow away from the measurement unit. With this, the caliper arm loads were reduced by 60% to guarantee secure and reliable measurement.

When running the tool it passes through the pipeline at product flow velocity. This may be too fast for precise measurements, as is the case at Langeled. If tool speed is diminished by flow rate reductions, costly throughput losses result for the duration of the inspection. For both reasons, it was important to overcome the high flow velocity without compromise to either measurement accuracy or pipeline capacity. Tool velocities during the actual combined ILI run, which took place in August 2009, ranged from 1.5 m/s to 3 m/s, resulting in a total traveling time of 127.3 hours. The average flow rate during the inspection was around 40 MMcm/d (1.4 tcf/d).

The length of the pipeline made tool wear another concern. Tool differential pressure increases with the higher friction in the smaller section of the pipeline. This was exacerbated by the pipeline's dual-diameter design.

To overcome this challenge, customized polyurethane cups were designed to limit tool wear during the passage through the 42-in. section while providing sufficient sealing and carrying capabilities in the 44-in. section. Since the differential pressure of the tool is determined by the magnet forces applied at different wall thicknesses and by cup friction, the magnet strength was optimized for Langeled to ensure full magnetic saturation while limiting the differential pressure and, hence, cup friction and wear.

Polyurethane cups on the front segment of the combo tool provide three sealing planes, giving a safety margin for cup wear and unintended bypass. Additional tool centralization to reduce cup wear in the first segment came from the magnetic forces themselves as well as from a supporting guide disc. In the rear segment, wheels supported centralization and improved run behavior. The average differential pressures measured during the actual inspection were 2 bar (0.2 MPa) in the 42-in. section and 0.8 bar (0.08 MPa) in the 44-in. section. The tool constantly rotated and was in a good condition upon receiving. •

References[1] Gjertveit, E.; Holme R.; Bruschi, R.; Zenobi, D.: The Langeled Project; 17th International Offshore and Polar Engineering Conference (ISOPE), July 2007, Lisbon, Portugal

[2] Beuker, T.; Brockhaus, S.; Ahlbrink, R.; McGee, M.: Addressing Challenging Environments –Advanced In-Line Inspection Solutions for Gas Pipelines; 24th World Gas Conference, October 2009, Argentina

More Offshore Issue Articles

Offshore Articles Archives

View Oil and Gas Articles on PennEnergy.com