Synthetic wire can be incorporated into traditional steel wire rope construction to offer the next generation of deepwater mooring solutions

Bridon International

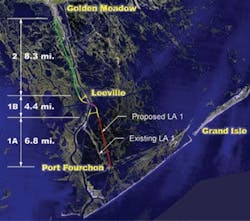

Floating facilities are an increasingly important solution for offshore oil and gas production and storage in deepwater or in areas of limited supporting infrastructure. Geographically, the use of floating production systems is widespread, which means the facilities operate in widely varying environments: from hurricanes in the Gulf of Mexico to congested production areas in Brazil, and the ultra deepwater of offshore West Africa.

By their nature, permanent moorings for production systems are required to offer long-term performance – in excess of 30 years, in some cases – while operating in potentially unexpected conditions. The demands on station-keeping equipment are continuously evolving, requiring novel and innovative approachs to equipment and materials.

Mooring cables systems have evolved over the last three decades, pushing the capabilities of known materials within their property ranges to match the current requirements of floating facilities.

Nevertheless, several limitations are being reached due to ever deeper locations and more extreme environments. Enhancements to materials and manufacturing innovations have shown effective improvements in weight saving and fatigue performance, but yet all appear to be reaching maturity.

An interesting and promising move in this direction came about when more untypical materials were investigated and assessed as part of a multiyear collaborative industry research and development program by Bridon and DuPont, with academic support from Leeds University in the UK. From those results, the application of a polymer processing method as a component for permanent mooring cables proved most promising, with advantages over existing solutions.

Mooring cable design

The composition of ropes has moved from natural fiber to steel with increasingly complex chemistries; to modern synthetic fiber; and now onto more exotic material. Yet the design remains the same: combine a series of small strength members to create a single, flexible, load-bearing rope. The strength of the individual components is aggregated and a loss factor is applied that considers the efficiency of the material within the given construction and termination type.

Parameters that influence the rope components include applied tensile load, lateral forces from neighboring components, any geometrical changes from axial direction of the component, friction between each component, and gripping forces from its termination. A rope is a complex machine with many moving parts, and the design factors relating to the chosen material must reflect this.

Rope versus tether

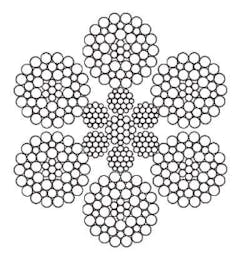

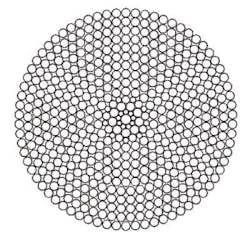

A wire rope comprises of a number of high tensile wires spun into a strand. Typically, six or eight of these strands are spun around a core of some kind. Larger wires may also be spun layer by layer in alternate directions to create a stiffer structural type rope, referred to as a spiral strand rope.

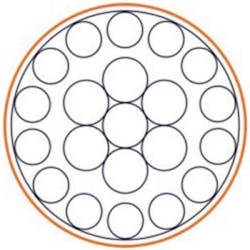

A synthetic tether construction comprises fibers spun into small ropes (sub-ropes), with the sub-ropes arranged into a parallel or long laid rope construction. Furthermore, there is a filter layer to prevent particle ingress and a braided jacket to maintain the structure of the rope.

A wire rope is mainly high tensile wires, and the physical properties of the wires can be modified through alloying additions to the steel chemistry and optimization of manufacturing. For the construction of a synthetic tether, on the other hand, different synthetic fibers are used to achieve the desired rope properties. A polyester fiber, for example, is used generally for permanent moorings.

Synthetic solutions

Steel and synthetic components each have benefits and limitations. The objective of Bridon’s latest research and development was to exploit a solution which offered the advantages of both the accepted solutions with reduced limitations. With the ever-increasing demand for deepwater applications, the challenge was to achieve a robust, yet lightweight mooring solution with performance and repeatable termination methods to moor permanent production facilities.

Typical spiral strand rope construction used for the synthetic wire rope trial.

Innovative material selection was married with a unique processing equipment and method developed by Bridon and Dupont to produce a synthetic wire similar in dimensions to a steel wire. This synthetic wire can be incorporated into the geometry of traditional steel wire rope constructions, thus leading to the development of what will perhaps be the next generation deepwater mooring solution. As the synthetic wires have properties closer to that of synthetic fibers but the with geometry of steel wire, there is also the potential for incorporation into combination ropes.

Synthetic wire properties

It was the collaborative approach between Bridon and Dupont that led to a successful development. Wire production, which starts with melt extrusion of polymer pellets to produce a rod, is then drawn into a synthetic wire with improved properties over the raw material. Key aspects of synthetic wire production include quality of the extruded rod and process control during the wire drawing. This is directly comparable to processing steel wire where similar challenges are met.

Manufacturing a prototype

The synthetic wires produced were used to manufacture a trial length of sheathed, spiral strand rope. The synthetic wire will accept a level of plastic deformation without damage, hence it is possible to impart a pre-formation to the wires to aid with consistent and precise rope manufacture, directly comparable to rope manufacture with steel wires.

An external sheathed jacket is applied for protection from handling or installation damage and, since its weight is not a concern, its presence does not deter performance. Initial investigations suggest that the sheathed jacket also increases stiffness of the product, and the prototype rope confirmed that the processing temperature of the jacket material is not detrimental to the properties of the wire.

Rope performance

Preliminary rope performance assessments were completed and verified through individual wire testing and small-scale modeling. Primarily, the breaking load performance of the synthetic wire rope was established and the design principles and efficiency factors for the material were verified. The aggregated breaking load of the synthetic wires, compared with the breaking load attained for the completed rope, gave a combined design and termination efficiency of approximately 20-25% compared to approximately 10% for steel construction. With more experience and as processing is refined, the apparent efficiency of the Bridon Synthesis assembly is expected to improve.

Conclusion

There is a need to optimize mooring component characteristics to better meet the challenges of the most extreme environments. Bridon’s latest product benefited from a collaborative approach to such challenges, where the collaboration has been extended to encompass the designers as well as end users who supported the drive for new materials. Already, there have been major advances in traditional materials that will improve strength-to-weight ratios for mooring applications. Investigations into novel materials requiring innovative processing have resulted in a new synthetic wire that demonstrates potential for a step change mooring solution while using conventional, proven wire rope constructions.

Acknowledgment

The author thanks Dr. Jagan Mohanraj, Bridon’s polymer scientist, and Steve Calverley, Bridon’s lead on Permanent Mooring Applications, for their contributions to the development of this article.

The author

Sara Fletcher has worked with Bridon for over 17 years. Having graduated from university with an Honours Degree in Mechanical Engineering, she now leads the Technical Development function within the offshore applications sector of the company.

Offshore Articles Archives

View Oil and Gas Articles on PennEnergy.com