3D ENGINEERING: 2% topside fabrication re-work cost increase beats 6% average

A design software system - PDMS or Plant Design Management System - helped reduce fabrication costs on Anadarko's Hickory platform, destined for Grand Isle Block 116 in the Gulf of Mexico. The project exceeded expectations on fabrication re-work at Gulf Island Fabrication.

Typical Gulf of Mexico projects experience up to a 6% cost increase during the fabrication phase due to necessary re-work, often resulting from piping clashes or interference. In contrast, the Hickory project experienced costs up to 2% to correct design errors. The cost savings on Hickory is an industry indicator of the value of 3D modeling - and the PDMS software in particular - and the role played by technology in driving down project costs while building in improved safety planning.

Using a PDMS model of the Hickory topsides, the Paragon Engineering Services project team performed a facility walk-through for early resolution of design clashes and early planning for operational safety through an anticipation of hazards and training of operations personnel.

Importantly, computer modeling represents a powerful tool with global impact for comprehensive life of field development and asset management. The offshore industry's greatest success using the tool will come from commitment to the technology, as computer modeling gains increased value with each project executed on a company's data base system. That is, with every equipment component (flanges, elbows, valves, etc) incorporated into the data base, system users have more information readily available to design subsequent facilities.

Experience adds value

The availability of such a comprehensive data base, together with an adeptness at using a computer modeling system, allows a company to effectively build a system that reflects its business culture and management approach to project execution. In this respect, 3D modeling becomes a management tool for working more efficiently while facilitating more time to pioneer design solutions.

Technology advancements in both hardware and software are facilitating more widespread use of 3D computer modeling for Gulf of Mexico offshore developments. User-friendly, PC-based platforms for 3D modeling applications are driving down costs for securing and using the technology while creating an improved business environment for a more efficient, cost-effective approach to offshore facilities design and development.

Over the last decade, the offshore industry has gradually gained improved efficiencies in platform jacket, deck, and topsides design with the use of 3D drafting design. The 3D design capability, however, has been limited to costly mainframe applications and cumbersome data base programs. The emergence of a PC-based operating system for 3D modeling and improved software applications is giving smaller engineering firms and independent oil and gas producers increased advantages using a technology that is flexible and cost-effective.

Fast-track schedule

The use of the software helped facilitate a fast-track schedule for the Anadarko installation in mid-August 2000. Paragon completed engineering/design services for the Hickory deck and topsides using PDMS software, designing the deck structure and all interconnect piping, piping supports, and the electrical cable tray system.

Paragon also used the software to design five skid packages: two separation skids, an oil shipping pump package, a cooling water package, and a gas dehydration package. The software helped minimize design conflicts and interference between structural, piping, electrical/instrumentation and other components for each of these skids.

Conventionally, 3D modeling systems provide a review of all design disciplines within a single composite drawing, helping engineers and designers identify design "clashes" or interference among components. Types of clashes include "hard to hard," meaning steel to steel, and "hard to soft," such as steel into a walkway. This progressive approach to offshore engineering helps to quickly discover and solve design problems in the drafting room rather than in the fabrication yard after steel has been ordered, cut, fabricated and assembled.

A PDMS-designed project requires a different approach, with additional up-front engineering and design effort required before creating a 3D computer model. A project team must first build a complete database of equipment information, including valves, flanges, pipe, fittings, vessels, skids, etc. The database ultimately holds the characteristics and properties, including physical dimensions, weights, sizes and wall thickness, of all facilities equipment.

To build an effective computer model, engineering concepts need to be closer to 70-80% complete, versus about 40% completed before standard 2D drafting commences. Advancing engineering design prior to beginning a 3D modeling effort yields overall drafting efficiency gains versus the traditional 2D drafted project. The efficiency comes from the ability to make "real time" solutions to design problems, which are readily identified in the 3D world, as opposed to the cyclic nature of creating, checking and correcting 2D plans and sections.

Product interfaces

The process of building a computer model, versus a traditional 2D plot plan, helps create a better-engineered product, requiring greater consideration of all components and their interface before producing any drawings. Most 3D data base models have the added benefit of automatically generating piping isometric drawings and material lists. At present, a single detailed pipe support drawing may require 30 man-hours to complete. Technology improvements are expected to reduce this time by half.

In making the transition to the software, Paragon adapted the technology to its business culture and method for executing projects. Most 3D software systems are configured to execute work based on a sequential order of events. While that approach may be appropriate in many manufacturing industries, Gulf of Mexico oil and gas projects require more flexibility, due to a lack of information and equipment data during the preliminary phase of a project. This dilemma makes designing and engineering a facility a challenge in the face of fasttrack schedules and pre-existing contracts for production startup.

Often, designers and fabricators work in parallel to complete an offshore project on time. This working environment requires a lot of communication between the operator and design firm so that changes can be made without significant impact on the schedule or total project cost. 3D modeling systems facilitate this process while minimizing fabrication contingency.

Concurrent projects

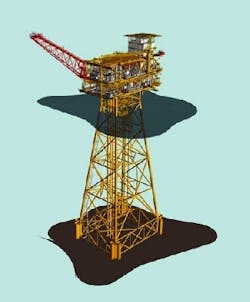

The Hickory project maintaining a fasttrack schedule and was completed in parallel with Anadarko's Tanzanite platform, a similar Gulf of Mexico project. This strategy facilitated use of available yard space while permitting the scheduling of Heerema's heavy-lift barge "SSCV Hermod" to install these two platforms back-to-back. The Hickory jacket sailed from Gulf Island Fabrication (Houma, Louisiana) in mid-August and the deck followed one week later.

Hookup and commissioning on Hickory was completed in early October. Both the Hickory and Tanzanite platforms are four-legged jackets designed for 324 ft and 315 ft of water, respectively. The Hickory and Tanzanite decks each weigh about 3,500 tons and 4,250 tons, respectively.

Anadarko commenced installation of the Tanzanite platform on Eugene Island Block 346 in late August and completed installation in early September. Enercon Engineering (Houston) completed design/engineering for both the Tanzanite and Hickory jackets and the Tanzanite deck. Aker Gulf Marine (Ingleside, Texas) fabricated the Tanzanite jacket and deck.

To make the concurrent projects a success, Anadarko maintained a core management team for both Hickory and Tanzanite to encourage commonality in terms of equipment used, process configuration, piping and instrumentation/electrical systems applied to achieve a consistent design and operating philosophy for both platforms.

Both platforms are designed to include programmable logic controllers rather than pneumatic air systems. This technology, while not new to the industry, represents a relatively new offshore system for Anadarko operations. Consistent design applications for both facilities also will lend flexibility in transferring operations personnel between the two platforms. Paragon worked closely with Anadarko to expedite purchase orders and track equipment. The concurrent projects, valued at approximately $100 million, provided economies of scale with common types of equipment ordered. In fact, valves, utility equipment, safety equipment and other common supplies were ordered simultaneously.

Dynamic computer modeling programs, such as PDMS, provide rapid progression from concept to construction while enhancing the design process with improved quality that comes from teamwork among designers, fabricators and potential operators of a facility.

Looking into the future, with the availability of electronic transfer, it's conceivable that fabricators may even cut steel from electronic spool sheets without human intervention. These technology advances are changing the complexion of the offshore industry, giving operators and service suppliers an opportunity for increased optimization and improved communication across all engineering and management disciplines.

Authors

W. Hickman Brown is a project manager with Paragon Engineering Services, Inc. Brown, who joined Paragon in 1990, has more than 24 years of experience in the design/engineering of offshore facilities and pipeline systems with companies such as Mobil, Superior, and Shell. He holds a BS in Mechanical Engineering from New Mexico State University and a MS in Ocean Engineering from the University of Rhode Island.

Mark E. Owen is manager of design services with Paragon Engineering Services, Inc. Owen, who joined Paragon in 1981, is responsible for the company's oil and gas design/drafting efforts, encompassing quality, manpower, estimating, and CAD software. He has 20 years of experience in the design of offshore oil and gas facilities.