Kerr-McGee applies lessons learned to latest GoM projects

John Cromb and Blake LaGrone; Kerr-McGee Oil & Gas Corp.

EExperience gained through the Nansen and Boomvang projects in the Gulf of Mexico helped Kerr-McGee in reducing rig time and associated cost savings at Gunnison and Red Hawk. The operator’s completion philosophy played a critical role in the success of the project.

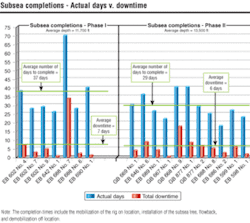

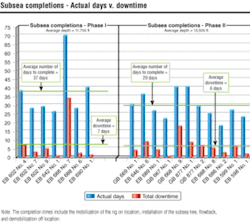

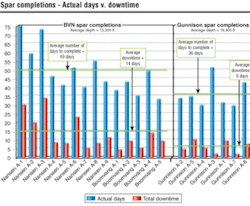

The Nansen and Boomvang fields are in 3,600-3,800 ft of water in the western GoM. From June 2001 to July 2003, Kerr-McGee completed 21 subsea and spar wells. Some of the technologies used for the completion implementation were unique, and the operator carried over many applied technologies from similar experiences at its Neptune spar and other operators’ projects. Kerr-McGee realized a steep learning curve during the program and captured the lessons and applied them successfully to the Gunnison, Red Hawk, and other outlying field developments.

Completion philosophy

The entire asset team agreed on a completion philosophy for each field prior to any well completion design. This proved highly beneficial throughout decision points in the well program, especially when the operator needed a critical resolution. For a difficult decision point, the group decided on the risk versus reward (i.e., stacking numerous gravel packs within one wellbore, installation of smart well equipment on an accessible surface tree, etc.).

For Nansen and Boomvang, the team favored a simplistic approach unless specific business needs warranted a more complex completion. It maintained this completion philosophy for the Gunnison and Red Hawk projects, except for necessary minor improvements.

The majority of the completion philosophies applied to both subsea and surface accessible spar wells. The design objective was to use field proven industry technology practices with the appropriate levels of quality assurance. The team assessed all new equipment for risk and analyzed it prior to use.

When multiple zones existed in a wellbore, the team’s basic philosophy was to design each well so that it stacked only two zones. On a few occasions, the team included a third zone in the completion design if a good economic driver was present.

For subsea wells, it minimized wireline operations where possible. At times, this increased the complexity of the completion equipment. When the equipment performed as designed, this philosophy was great. However, there were times when in attempting to minimize wireline operations, the additional complexity proved to be detrimental to the overall completion plan. Fortunately, a close relationship existed with the completion equipment suppliers. The suppliers diagnosed equipment failures quickly and implemented design changes so that future wells did not have the same problem.

Rig selection

The team selected rigs for the subsea wells based on parameters such as rig crane requirements, moon pool dimension requirements, BOP stack requirements and deck space.

The rig crane had to handle the largest lift within the dynamic conditions for which it was designed. In all cases, the horizontal subsea tree was the largest lift at approximately 90,000 lb for the Nansen, Boomvang, Gunnison, and Red Hawk developments.

The moon pool dimension was a critical requirement for subsea tree deployment and retrieval. It had to be large enough to accept the subsea tree. Also, the team had to consider how to move the subsea tree into the moon pool and position it to be deployed once it was offloaded.

The BOP stack had to be rated for the intended service and interference tested with the subsea tree to make sure there were not any issues with land-out.

Adequate working deck space on the rig was essential to ensure a cost-effective, efficient, and safe operation. During the completion tubing installation, it was necessary to have the subsea test tree equipment, the completion tubing and accessories, and the control line spooling units installed on the work deck and accessible to the rig floor. In addition, it would have been cost prohibitive if the surface well test equipment was not already installed and ready for flow back and clean-up at the same time. Using a tender assist approach from a boat for any of these items would be dependent on weather conditions.

Rig design

The Nansen, Boomvang, and Gunnison spar projects benefited by having a rig built or upgraded in the yard during the months preceding the installation. Drilling supervisors, completion engineers, and rig contractor design engineers worked together ahead of time to configure the rig and optimize the layout to benefit the completion operations.

Nansen and Boomvang were the first truss spar installations, and many of the lessons learned from the classic spar design directly applied. However, there were several unexpected operational challenges.

One area of concern was that the truss spar and classic spar design had different motion characteristics. Although Boomvang and Nansen were both truss spars and were only 7 mi apart, each had a different motion response.

It was not uncommon to have one rig operating while the other could not under the same weather environment. A 100% increase in weather related downtime was realized. The riser installation and BOP installation were the most weather sensitive, since large, heavy equipment required deployment below the rotary and was very susceptible to movement. Working closely with the spar and rig contractor design engineers, the team moved the BOP stack 46 ft higher on the Gunnison spar to minimize motion during installation operations. This also provided additional benefits because the team could leave the control line hoses intact during that time.

In an effort to test the intelligent well system technology, Kerr-McGee installed its first system on a shelf well in 2000. This basic intelligent well system provided control of two zones via sliding sleeves using three hydraulic control lines.

Due to the mechanical and operational success, six of the first seven Nansen and Boomvang subsea wells incorporated the intelligent well system. To provide flexibility, all of the subsea trees and tubing hangers could accommodate a smart system. Kerr-McGee presently has completed 20 intelligent well systems with excellent results.

Wellbore preparation

Wellbore preparation was critical to eliminating additional rig time during cleanout and displacement to completion fluid. The operator left most suspended wells with water-based mud and cement plugs per regulatory requirements. If there was no reason to believe that the production casing had been compromised, Kerr-McGee typically made an indirect displacement from the water-based mud to seawater.

The operator used various sweeps and surfactants to get the contaminants out of the wellbore. In most cases, the operator employed a full suite of brushes and scrapers to assist in a complete wellbore cleanout. Once Kerr-McGee felt the casing was sufficiently clean, it made a displacement to completion fluid.

In general, the team planned cement evaluation logs for all wells. If the operator was confident that the primary cement job was placed as planned, logging operations could be done after the wellbore was displaced to completion fluid, thus avoiding an extra displacement to mud.

In the deepwater environment, cement evaluation of the primary cement job was critical to validate that isolation of the hydrocarbons existed. Typically, evaluation logs were run and followed with a gauge ring/junk basket prior to installation of the sump packer on wireline.

Perforating

The perforating design consisted of tubing conveyed perforating with a 500-1,000 psi under balance with an air cushion. The team perforated the zone on an open choke and conducted an immediate flow back of 20-30 bbl to clean perforation tunnels. The guns selected for the well provided the maximum well productivity within the parameters for a given casing size based on shot density and gun performance.

Typically, the team ran 7-in. guns inside 9 5/8-in. and 9 7/8-in. casing, and 4 1/2-in. guns inside 7-in. and 7 5/8-in. casing. After perforating and flowing back, the team shut in the well downhole using a ball valve type test tool for 30 min. to conduct a build up on the formation. Once the build up was complete, it conducted a fluid loss check, and if losses were greater than 10 bbl/hr, the team spotted an HEC pill before to pulling the guns out of the hole.

In the event that the zone was adjacent to two casing strings, the team performed an additional perforation surge to confirm connectivity to the reservoir.

Sand control

The additional cost and expense that the operator would incur if sand production occurred on a deepwater well led Kerr-McGee to provide sand control on all of the deepwater wells.

In addition to a gravel pack, the asset team also used a pre-pack screen as a secondary barrier to sand. It conducted either a high-rate water pack (above frac pressures) or a frac-pack, depending on the permeability and proximity of water. Typically, the asset team completed all zones with perforated lengths less than 130 ft and if longer, it determined if the best method was to break the zone up into multiple intervals or use an alternate path technology.

For fluid loss control on the single selective wells, the asset team used a concentric isolation string with sliding sleeves that operated with wash pipe. On single completions, it employed this method as well, but at other times, the team used a flapper valve or equivalent type fluid loss control device.

The typical deepwater completion tubing design included a downhole pressure and temperature gauge, deep-set nitrogen charged tubing retrievable surface controlled subsurface safety valve (SCSSV), and two chemical injection valves used for methanol and chemical injection.

The asset team placed the methanol injection valve where the ambient temperatures were above the hydrate point, and it placed the chemical injection valve just below where any paraffin wax may be an issue. The SCSSV had to meet both flow assurance design criteria, so the team placed it below the hydrate point and wax appearance point.

In an effort to standardize equipment and not have excessive stock, it designed the completion string to the worst operating environment expected over the next two-year period. A metallurgy study of the various planned developments led to the standardization on all flow wetted components at 13 chrome 110 ksi Hyper-1 (or SuperChrome). This was beneficial from a sourcing standpoint because the suppliers kept adequate spares in inventory to cover any completions or unanticipated workovers.

Well cleanup

On subsea wells, the asset team performed a short cleanup and flow back of hydrocarbons to the rig through portable well test equipment and located a water curtain spray on the rig to control the heat radiation. Next, the team flared the gas and pumped all liquids to a US Coast Guard approved barge.

The water depths of these deepwater wells ranged from 3,250 to 5,300 ft. Most of the wells had multiple zones and were intelligent well completions. The bottomhole pressure was less than 10,000 psi, and the bottomhole temperature was less than 175° F. On the smart wells, the asset team separately cleaned up each zone.

The objective for each well during the cleanup was to verify that the completion would produce sand free, that the critical components in the completion operated as designed, and a that flow rate was achieved that would be similar to the rates that the operator planned.

On the spar wells at Nansen and Boomvang, the goal for the flow back and cleanup was to get the well flowing on its own and then turn it over to the production operations team for further cleanup and testing.

Typically, after the team installed the surface tree and put in the control systems, it installed a riser back to the rig floor and gas lifted the well using nitrogen to the rig’s gas buster until hydrocarbons were detected. Then the team shut in the well and turned it over to production.

On the Gunnison spar, Kerr-McGee installed a nitrogen generation unit that allowed all clean-up activities to be done offline while the rig continued with the next completion.

The lessons Kerr-McGee and its asset team learned at Nansen and Boomvang and applied to subsequent projects at Gunnison and Red Hawk contributed to a very impressive reduction in rig time and associated cost savings. Critical to the success of the projects was a completion philosophy for planning and direction. Other key components to making the lessons learned work as intended include:

- Focus on the areas that have the most impact

- React quickly when necessary

- Document lessons as they happen

- Keep all lines of communication open (from the rig crew to the design engineer).

Editor’s Note: This is a summary of the Successful Adaptation of Deepwater Completions Utilizing Prior Experiences from the Nansen and Boomvang fields paper presented at the DOT conference on Nov. 30, 2004 in New Orleans, La.

The Nansen and Boomvang spar completions consisted of 14 wells (one smart), with an average completion time of 49 days. The Gunnison spar completions consisted of seven wells (zero smart) with an average completion time of 36 days. Kerr-McGee reduced the average well cost by 11%, even with the average well depth at Gunnison being 3,500 ft deeper.