Water jet cutting an option throughout structure's life

Jonathon Miller

Michael Aleksines

InterMoor

Technology advancements in recent years have enabled amazing things in offshore oil and gas developments. High-strength steels have been developed that make structures lighter and more efficient. In order to maximize the performance of the steel, techniques have been developed that make it possible to sever steel plates with no heat affected zone (HAZ). Heat affected zones occur with all hot work cutting methods (oxyfuel torch, plasma, etc.) and change the characteristics of the material around the area where the cutting or welding occurs. Those changes can affect material hardness and weldability, and can cause discoloration or distortion.

Abrasive water jet cutting technology cuts through steel without creating a heat affected zone. This enabling technology has been used on end-of-life operations for years, and recently was employed on two topsides operations for a major operator.

Hot work is an effective and efficient way to process steel structural members for offshore construction. In many applications, the precision achieved and final properties of steel members that are fabricated using hot work methods fall within acceptable limits. There are, however, applications where the heat affected zone created by the high temperatures of hot work cause problems that can limit the final product's performance. Heat-treated steel products that are cut using hot work methods have zones where the heating causes grain growth in the material adjacent to the cutting area. This grain growth and any other tempering effects caused by elevated temperatures combine to reduce the strength of the steel. In these instances, alternative cutting methods are required.

For obvious reasons, it is preferred that offshore fabrication or structural modifications to hydrocarbon producing structures should be non-sparking. Performing cutting operations in a submerged environment makes the abrasive cutting virtually spark-free.

Technology development

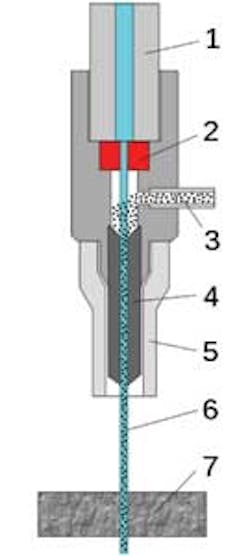

In the 1950s, Dr. Norman Franz, a forestry engineer searching for new ways of cutting trees into lumber, became the first person to study ultra-high pressure (> 30,000 psi) water as a cutting method. He used free-falling weights to push a column of water through very small openings to generate highly pressurized jet streams. Though the forces used to create the needed pressures are very different today, the nozzle arrangement is not.

Water jet technology progressed rapidly in the 1970s, led by research and development at Flow International Corp. With abrasives added to the jet stream, the high-pressure water gained the needed inertia to cut through materials that are much harder and tougher than lumber. Water jets can cut through a variety of metals, glass, ceramics, concrete, rock, and other materials. Advantages of water jet cutting include a mechanically simple system, inherent quenching and cooling of the part being cut, and no heat affected zone.

Several iterations have been performed in the design and development of water jet systems, and the technology has made dramatic improvements using a variety of specialized materials to improve the wear of the components. In the 1980s, abrasive water jet technology was applied to decommissioning activities. A system was developed that made it possible to cut through pin piles below the mudline so the structures could be toppled in place for an artificial reef or brought to shore for recycling and reuse.

In 2006, the Two-Axis Shape Cutter (TASC) was developed. TASC takes water jet technology and makes it accessible in a variety of field applications. Straight line cuts in the x and y directions can easily be made. By following a template, a radius can be created with some accuracy.

In 2012, multi-string conductor cutting was introduced. The system is capable of cutting grouted conductors ranging from 75⁄8-in. inside diameter to 36-in. diameter.

Recent applications

Water jet cutting technology can be the appropriate option at any stage in a structure's life, from onshore construction to offshore decommissioning.

Early in 2013, Kiewit Offshore Services was completing the topsides fabrication for an offshore platform. Because of client performance requirements, it became necessary to find a way to cut 72 slots measuring 5 in. in width by 9 in. in length in two capping beams for the well bay module of the platform. Several options were considered, and abrasive water jet cutting was selected because of the post-cut characteristics of the steel and concerns about the integrity of the fireproofed area under the locations of interest. The capping beams were composed of 3.5-in. thick steel. Because of existing infrastructure below the capping beams, it was necessary to find ways to prevent the spray of sparks and slag from flame cutting options. InterMoor, an Acteon company, applied abrasive cutting technology and developed a method of slowing the transonic jet emanating from the cutting nozzle to protect the personnel and equipment below.

A crew and equipment were mobilized and deployed to the Kiewit yard early in 2013 to perform the operations. After arriving and setting up the equipment, the crew performed a sample test cut to verify that the dimensions of the template were within the specified tolerances.

Upon approval of the test cuts, the crew moved the template to the capping beam to perform the cutting operations. To meet position tolerances for each template, the deck was surveyed and the centerlines for each location marked on the capping beam. With the client representative's approval of the template position, cutting was performed.

Many semisubmersible and TLP hulls are shipped to the regions where they will be deployed for topsides installation at a shore base. These shipments occur on specialized transportation vessels. Sea fastenings are often welded to the deck of the delivery vessel and to the hull that is being transported. To save operating costs and reduce the need for re-work, it is important that when the sea fastening plates are removed, minimal loss in original dimensions occurs. It is also important that no loss of material properties occurs from the hot work methods mentioned previously, as the future sea fastenings could fail prematurely. Removal time for cutting operations is estimated to fit easily within a two-day window of opportunity.

In 2008, a major operator used the TASC system to cut 60 slots (2 ¾-in. wide by 8-in. long) in two 3-in. thick capping beams on an offshore TLP. By creating these slots, the drilling tower could be installed and moved around the structure as needed for normal drilling operations. Operations occurred offshore on the structure without safety incidents.

Decommissioning

In 2010, the (then) Minerals Management Service issued Notice to Leaseholders (NTL) 2010-G05 which redefined the regulations for producing and idle wells on the outer continental shelf. The new way of defining the structures dramatically increased the number of structures that needed to be decommissioned and made it necessary to remove these structures within three years of the issuance of the NTL. The number of idle wells climbed to more than 50%, and structures in the idle iron category reached 42%.

The first step in decommissioning a fixed platform is to shut-in the well and remove equipment for salvage or scrap. Often the topsides is removed as a package and hauled to shore on a barge. To sever the topsides, traditional hot work methods or abrasive water jet cutting services may be used. The latter uses a magnetic track to connect to the work piece and be a guide for the cutting tool to follow its course around the structure. Cutting is done at a height of 10-20 ft (3-6 m) above the water line.

Water jet technology can remove fixed structures from the seafloor as well. The tool is deployed through the leg of the jacket and lowered to a predetermined depth below the mudline. At depth, it is centralized, and the swing arm is extended to make contact with the wall. When the water jet is activated, a pre-cut wash begins, followed by the cutting. When the circumference has been cut, it is possible to test load the pin pile to verify that it was adequately severed. Afterward, the tool is recovered to the surface and lowered into another jacket leg. When all legs are severed, the jacket is recovered to the surface and hauled to shore or an artificial reefing site.

When removing fixed structures from the seafloor, the multi-string conductors must first be removed. These can be removed explosively, via mechanical cutting, or with abrasive water jet cutting technology. Each option has benefits and drawbacks.

There are other applications where water jet technologies can be used:

- Cutting access ports in hulls, chain lockers, tanks, or basins

- Removal of obsolete infrastructure such as riser tubes, cells in a cell spar structure, or any other tubular shape

- Removal of structural members to make room for equipment revisions

- Sectioning of topsides so it can be removed for decommissioning

- Removal of heavy-lift pad eyes after installation of topsides on hull.

The list above is not exhaustive. New applications for this technology are discovered regularly.

Oil and gas developments have progressed significantly in the last several decades. This progress has been aided by the development of abrasive water jet technologies, which can be used for a variety of applications from the cradle to the grave of a structure.