High quality electronics key to drilling HP/HT environments

Tougher conditions forces industry to search for better electronics

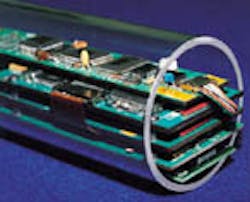

TEMs are high-density electronic modules configured from multiple horizontal printed circuit boards, interlaced with nano-miniature connectors in a tubular array.

Current electronic components operate normally to approximately 350°F, where erratic performance or in most cases, catastrophic failures start to occur. The problem is not specific to any one vendor. Service providers currently use similar electronics in their downhole tools. The difference in their respective products is in packaging and configuration of the electronics.

Another electronics industry trend is that vendors supplying service companies with electrical components are decreasing the qualification specifications of their products. This comes as a result of the electronics industry adopting lower, more cost effective standards set forth in the customer off the shelf (COTS) policy the government has implemented.

Stringent military specifications are no longer the minimum for consumer electronics. As a result, the oil and gas industry, being a relatively small consumer in the global electronic component market, is experiencing difficulty purchasing capable components for downhole tools and equipment. Also, being a relatively small consumer in a global market makes it difficult to convince electronics manufacturers to build components to oil and gas industry specifications and at reasonable cost.

To better understand the problems of current technology and the future needs of the industry, a more detailed explanation of the tubular electronic module (TEM) follows.

Tubular electronic module

Petroleum drilling cost reduction, direction control, and reduced diameter are constant challenges in high technology drilling, seismic imaging analysis, as well as downhole sensor monitoring. All are used to reduce cost and time, and improve the accuracy of potential field evaluations. Exploration and monitoring methods are evolving rapidly with high capacity computers and the further development of digital electronic modules (DEM).These tubular electronic modules contain sophisticated integrated circuit chip sets with interactive software to provide improved directional drilling control, image storage, and downhole sensor data processing. Modules are placed near the bit end of the drilling or sensor system to improve signal integrity and reduce signal time lag.

Electronic evolution

Silicon chip design has evolved significantly in the ability to detect, analyze, store, and send data using digital methods. Thus, significant levels of data processing can be achieved rapidly and sent to the control and monitoring systems. Digital signal technology requires significantly smaller wires for routing data to and from sensor and control systems.The smaller wires and smaller connectors are combined with careful stacking of surface-mounted printed circuit cards to yield a significant size reduction which provides smaller diameter electronics for wellbore and shipboard electronic systems. Improved digital electronics often delivers significantly more quantitative and timely information.

Size is often equated with ruggedness in the petroleum industry. However, in electronic systems, recent material and design methods have broken that paradigm. New wire alloys and insulation methods have allowed size reductions to match the evolution in digital tech nology. Complex TEMs are currently applicable in 2 in. and 3 in. diameter environments. Historically, connectors have been large, with pin-to-pin spacing of 50-100 mils. These connectors were often 3 to 4 in. square. New designs are now available that range in fractions of an inch.

Demand for smaller systems

Electronic systems are subject to demanding performance and reliability requirements. These two demands have expanded with the evolution of digital electronics. Specifica tions for connector systems list the following:- Size reduction

- Vibration survival

- High thermal exposure

- Contact with oil/water

- Rugged handling during mate/de-mate

- Exceptional electrical performance.

Applications requiring in-line signal routing, right-angle cable plugs and panel mounted systems are environmentally sealed when necessary. Direct board mount connectors mating to in-line cable systems also help reduce space requirements while maintaining high reliability. Higher temperature capability, constant vibration capacity, and continuous data transmission integrity evolved from designs and materials also required in space electronics.

Contact design

To meet the demanding requirements of downhole electronics, additional focus on materials and design methods are required. The main challenge is in size reduction of connector systems while maintaining the rugged requirements necessary for the petroleum industry. The connector contact design becomes a key element in vibration and electrical performance assurance. To achieve this, seamless, one-piece beryllium copper contacts, plated with burnished gold are used.The tubular receptacle is "dimpled" such that the pin is pushed firmly against the inside diameter of the receptacle. This sealed tube-in-a-tube technique significantly increases the ability to withstand shock and vibration, or any tendency to set-up sinusoidal harmonics during constant vibration.

The connector pin and socket elements are crimped to high temperature wire without need for solder. This provides the highest thermal performance. The crimped pins and wires are then molded into petroleum and space grade insulators that are encased in metal housings. This construction process has proven itself in a number of leading edge electronic systems used in today's petroleum industry.

Today's petroleum engineers are increasingly using high-speed electronic systems to monitor and control drilling equipment. The nano-miniature connector is used in-line with many of the high technology systems to push performance beyond its previous limits. The engineer designing systems in petroleum signal management is constantly constrained by space and environmental capacity limits.

The new nano-miniature connector and miniature cable systems are solving many problems. Electronic systems are being converted to higher speed digital electronics with the capability to monitor and process extensive data from multiple sources. Key requirements such as physical impact resistance, high temperature, and exposure to petroleum and water are key concerns that are currently being solved.

Continuous vibration is less of a problem with the lower mass electronics. Future systems will continue to emerge that use higher electronic technology to enhance accuracy, performance, and reduce the costs of drilling and monitoring technology.

Acknowledgement

Robert Stanton is a substantial contributor to this article. He designed and worked with the drilling industry electronic systems for over 20 years. He is currently Sr. Applications Engineer at Nanonics Corporation (Phoenix, Arizona).

Materials design for high temperature interconnection systems

Extreme-environment electronics require innovative design criteria and rigorous qualification testing. Electrical hardware is only as reliable as its weakest component. This includes electrical solders and pin crimps for mechanical attachment.- High temperature contact system: Electrical contacts currently feature burnished seamless gold bore surfaces throughout the tubular pins and sockets. The one-piece contacts are coined from BeCu and are Ni/Au plated on inside and all outside surfaces. To withstand temperature applications up to 225°C, the teflon insulated wires are stripped and crimped. The proprietary crimp process includes rate, pressure, and a hold-time, setting a "crimp-memory" into the material to prevent contact relaxation.

- Liquid crystal polymer insulators: Selection of insulator material is critical for high temperature operation. For the downhole environment of the oil and gas industry, a liquid crystal polymer (LCP), loaded with 30% glass fiber is used.

- Potting material for vibration and temp erature: A NASA-certified single-part epoxy designed for low outgassing and high temperature performance is used currently. The CF-3003 from Frey Engineering is rated for operational temperatures above 225°C. Its hydrolitic hardness stability remains at a shore hardness of 70D at 225°C. The epoxy captures the back of the pins and controls the exit of the wires out of the back of the connector body. This material is critical to allowing the connector system to withstand long term high temperatures in a constant vibration mode. Adhesion of the material to the LCP insulator body is also critical, and enhanced using the fore-mentioned plasma processing steps.

- High temperature solder: If connectors are to be soldered directly to printed circuit boards, they are crimped with gold plated, 1/2 hard brass lead frames instead of wires. The lead frames exit the potting material in a similar format to the teflon wires and are formed into gull-wing shapes for soldering. High temperature solder of 5% Tin and 95% lead is often used. Since the solder melts at 312°C, the process temperature and time must be controlled to limit exposure to the connector assembly. Mating inserts are often used to heat sink the connector body during solder re-flow processing at high temperatures. This temporarily increases the connector mass and eliminates potential epoxy slumping during the temperature elevated soldering process.

- Testing and qualification: The key to achieving good performance at elevated temperatures is selecting only materials that exceed the expectations and integrating them in a design that coordinates any stress forces to achieve that goal.

Vibration testing has shown that these nano-connector systems exceed performance expectations of Mil-Std-1344 method 2005, test condition IV. Mechanical shock has exceeded most typical specifications plus some extreme applications.

Copyright 1999 Oil & Gas Journal. All Rights Reserved.