Extendable draft platform offers drilling flexibility

Design opens new areas to floating production

Judy Maksoud

International Editor

Technip's newly introduced extendable draft platform (EDP) is an evolution-ary floating production concept. According to John Murray, principal engineer, Technip has combined the best features of deep-draft semisubmer-sibles, truss spars, and other reduced-heave floaters to produce a flexible deepwater production system.

"The EDP is not a new technology, but rather a new application of existing technology," Murray said. The result is a design that incorporates some of the best characteristics of other floating production concepts.

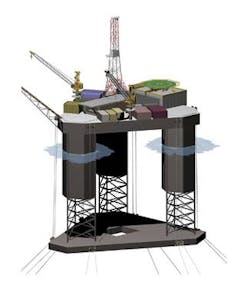

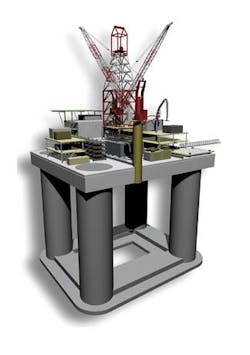

Once the platform is installed, it functions as a deep-draft semisubmersible. A plus for this design is that because the vessel is column-stabilized and most of the lower hull is not required for buoyancy, the EDP requires less steel than traditional semisubmersibles.

The unit uses the added mass effects of the heave plate of the truss spar to increase the heave period. The EDP's in-place motions are superior to shallower-draft floaters for supporting dry-tree risers and steel catenary risers (SCRs), Murray said.

"We have found in some cases that the improvement over the conventional semisubmersible is significant and can accommodate steel catenary risers. This is because the reduced motions significantly reduce the amount of fatigue damage. The result is a considerable saving in riser costs," Murray said.

According to Technip, the excellent motion performance accommodates both dry-tree well completions (top tensioned risers) and subsea wells.

"Extensive analysis has shown the riser technology developed for the spar can be ported directly to the EDP. The top tensioned risers (TTRs) are used for production and SCRs are used to export production to an offloading site or to a gathering pipeline network. SCRs or flexibles can be connected to the EDP either by porches external to the hull or by pull tubes internal to the columns," Murray said. These installation methods are attractive for adding future tiebacks to the installation.

null

Construction

The EDP is a self-installing design that delivers and deploys an operational system without the requirement for a crane vessel. The structure consists of a floatable deck, stabilizing columns, and a heave plate connected to the bottom of the columns. The mooring system is made up of several lines extending down the columns into a spread pattern. Mooring lines can be wire and chain or polyester and chain. The barge-type deck is designed to float the entire structure, including topsides, to the site.

When the EDP arrives on site, the columns and heave plate are lowered and latched into the deck. Then, the deck is raised to the operating elevation by de-ballasting the columns. "When it arrives on location, it is ready to go in a day or two," Murray said.

The lowering system, which according to Murray is the most novel application, is used on the Technip 3300 jackup platform. "We have assembled a group of subcontracted engineering companies to aid in the design of the system, and again, it is based on equipment already in used in various parts of the industry," Murray said.

The lowering system uses the onboard mooring system. Hydraulic winches, controlled by a central unit, lower the heave plate and columns. A number of locking mechanisms have been developed to connect the column and deck.

Another important feature of the self-installing design is that the process can be reversed easily to de-mobilize the EDP and return to port for re-fitting or redeployment.

The EDP offers considerable flexibility in construction and delivery schemes that can be applied to a large number of fabrication facilities worldwide. The columns, heave plate, and deck are of conventional steel hull construction and can be fabricated at a number of sites.

The primary requirement for the construction site is a shallow-water docking facility. The EDP requires a water depth of only six to eight m for topsides integration and outfitting. Most sites can be easily modified to accommodate assembly and construction. Furthermore, major structural components and topsides modules can be fabricated concurrently.

The topsides are fabricated as conventional modules that can be lifted or skidded onto the deck at quayside. The complete system can be integrated and commissioned dockside. Since the deck of the EDP in its delivery configuration is essentially at dock elevation, the topside modules can be skidded onto the deck platform without the high lifting typically required for TLPs. Also, a jacking system can be used to assemble the columns in sections.

Minimal construction requirements mean the EDP can be built in many yards around the world using local content in engineering, fabrication, and construction and using the available infrastructure.

Technip has also been working with a company that specializes in designs and delivery of integrated drill rig packages, Murray said.

Packages specific to the EDP have been developed in concept and are included in the platform designs developed by Technip. Designs that can be interchanged on the EDP, depending upon the requirements at a particular stage of field development have also been considered.

"These design options are particularly advantageous when in a staged development approach utilizing the EDP," Murray said.

null

Flexibility

Developers of the EDP say the design offers a deepwater solution that is adaptable to a wide range of operating requirements, including full drilling operations.

Another critical point in application of the EDP is that drilling, completion, production, and work-overs can be completed from the same floating unit, Murray said.

Recent developments are focusing on the flexibility of the EDP, specifically in design, construction, and delivery. Designs for the Caspian Sea, offshore Brazil, West Africa, and the Gulf of Mexico are physically different but conceptually similar.

"The idea of floating a commissioned, self-installing system to the deployment site is the same," Murray said.

During 2003, Technip's R&D department initiated a major program to investigate the technical and economic feasibility of the EDP.

"This effort involved developing computer models for sizing tools and analysis techniques. An extensive series of model tests was also commissioned as part of the project," Murray said.

null

null

The company also ran several economic analyses for different regions, comparing the EDP to an FPSO and a traditional semisubmersible. "The result was an attractive difference in the overall economics in favor of the EDP," Murray said.

Though testing and analysis have demonstrated the feasibility of the EDP, the proof of the pudding is in the eating of it.

"We are convinced that it is an excellent product. But of course, the most difficult hurdle of any new product is convincing clients to make an investment in the first system. Our technology is aimed at the economics," Murray said.

The EDP's constructability, flexibility, and versatility will place it in operation some time soon, and the results will determine the future application of this innovative design.