New tools and technology for the offshore industry - Simulator aids control of fluid behavioral changes

Scandpower's UBitTS is proving to be a valuable tool for tackling the challenges of underbalanced drilling (UBD). The UbiTS – underbalanced interactive transient training simulator – is derived from the Oslo-based company's OLGA 2000 software program for modeling multiphase flow.

At OLGA 2000's core is a technology for analyzing and predicting the transient behavior of multiphase fluids. But whereas OLGA is directed at the wellstream from one or several wells as it flows through the well or down a pipeline, UBitTS focuses on the dynamic situation downhole as during underbalanced drilling.

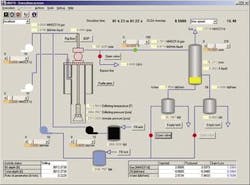

The graphical user interface from Scandpower's UBitTS simulator displays input of well and reservoir data.

null

In conventional overbalanced drilling, the specific weight of the drilling mud column is used to create a higher bottom-hole pressure than the reservoir pressure, thus keeping the reservoir fluids in place. In the process, formation damage can occur, impairing the reservoir flow performance and resulting in lost production.

By using a lower weight of drilling fluids and allowing the reservoir to produce during the drilling operations, UBD – or managed pressure drilling, as it is also called – reduces the risk of formation damage while offering other advantages such as the provision of early information about the reservoir, increased rate of penetration, and the avoidance of differential sticking. Although UBD can be more expensive than overbalanced drilling in the short term, increased production may make it more cost-effective in the longer term. For UBD to be practical and safe, however, it is necessary to maintain control of events downhole, responding quickly to changes, especially in pressure. Based on the input of well and reservoir data, UBitTS is able to predict transient fluid behavior downhole, and to analyze what changes in parameters such as mud weight, viscosity, and back pressure are required to achieve a more stable flow, or, ultimately, to kill the well.

Once the well has been completed and brought on stream, UBitTS can be applied to monitoring of underbalanced production operations, providing real-time simulations, which enable relevant parameters to be modified to optimize output.

Feedback from users on the dynamic simulator has been good, according to Scandpower marketing executive Amundsen. Well personnel and drilling contractors need this kind of technology to familiarize themselves with dynamic behavior in wells, and it has been an eye-opener for many drilling and well engineers, he says. The tool has been acquired by Shell, one of the pioneers of UBD, which is using it at a number of locations around the world.

As UBD is increasing used by the oil industry, drilling personnel need to be trained in its use. In this respect UBitTS doubles as a training tool, enabling personnel to become familiar with UBD operations and scenarios in a virtual situation.

The development of UBitTS was carried out jointly by Scandpower and drilling consultants Blade Energy Partners of the US, which provided the drilling input.