POWER GENERATION: Record distance platform-shore power supply aids Valhall redevelopment

BP is to use ABB’s High Voltage Direct Current (HVDC) Light technology in the redevelopment of the Valhall Field in the Norwegian sector. Under a contract worth $50 million, ABB Power Technologies will supply the converter stations to enable power to be supplied from shore to run the field facilities, including a new production and quarters platform.

Under the redevelopment plan, which will be submitted for government approval later this year, 78 MW of power will be supplied from shore to the field over a distance of 292 km. The distance is four times the first offshore application of the technology, at Troll, where an HVDC Light system transmits power 70 km from shore to Statoil’s Troll A platform. At 80MW, the total power supplied on Troll is close to that required for Valhall.

The HVDC Light system at Troll has been in operation since last October. So far the operating experience has been very good, without any disturbances to the power supply, according to Lars Carlsson, ABB’s Valhall project manager.

Valhall is currently powered by gas turbines, the carbon dioxide emissions from which are subject to Norway’s offshore CO2 tax. The decision to switch to power from shore was driven by several considerations. According to Sverre Gilje, BP’s project manager for the power project, it is intended to:

- reduce the capex and opex and improve the operational efficiency of the field

- minimize emission of greenhouse gases

- improve all HSE elements.

“ABB’s HVDC Light system has made this possible for the Valhall Redevelopment project,” Gilje says. “In addition to the above mentioned elements, this power supply system will give us a very high quality supply regarding voltage and frequency even during direct online start-up of the large gas compressor motors, and there will be no need for additional soft start equipment.

“Very few companies can offer a similar power supply system, and no others have such a system in operation per today.”

The solution is environmentally friendly, especially as the grid power is produced mainly by hydroelectric plants. At peak, the use of power from shore will eliminate an annual 300,000 tonnes of CO2 and 250 tonnes of nitrogen oxide, compared with a combined cycle power plant with low NOx gas turbines. The HVDC Light system also offers very high availability - 98.5-99% - and a much lower maintenance requirement than gas turbines.

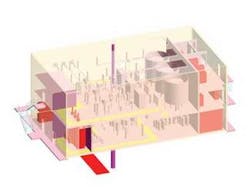

It also achieves a high level of efficiency in transmission, with almost 90% of the power in-feed on shore delivered to the platform AC system at full load, despite the long distance. The performance of gas turbines in an offshore context leaves much to be desired, with an efficiency of energy generation even for newer installations typically of only 30-35%. The HVDC module also has relatively modest weight and space requirements, measuring 30 m x 17 m x 13.6 m and weighing approximately 1,000 tonnes.

The module will also contain the auxiliary systems, including the valve cooling, ventilation and auxiliary power systems. The ventilation systems, both in the module and the onshore station, will be designed to protect the high-voltage equipment and the electronics from salt and humid air. The module will be over-pressurized to ensure that no gas can enter the high-voltage areas. If gas is detected, the system will be automatically tripped and de-energized.

Transistors instead of thyristors

Power has been transmitted in HVDC form for more than half a century, but a breakthrough was needed to enable HVDC power to be applied offshore. This was mainly achieved through the selection of transistors in place of the thyristors used in conventional HVDC systems.

ABB has also developed its MACH 2 control system for use with HVDC Light. While the operator sets the power load to be transmitted, MACH 2 automatically takes care of the functioning of the system, controlling the flow of current through the transistors. The only communication required for transmission is through the DC voltage on the cable. The control system also ensures smooth delivery of power during critical periods, for instance when large power consumers like compressor motors are switched on.

A dynamic performance study has been carried out to verify the functioning of the Valhall HVDC Light system. The study modeled the electrical system on the platform, the converters, regulators and cable and the land station. Both normal and abnormal events, such as flashovers and ground faults due to insulation failure in the cable, were introduced, to see how the system responded. The results of the study were used to optimize the system response to such events, Carlsson says.

For further information contact Lars Carlsson, ABB Power Technologies. Tel +46 240 78 33 35, fax +46 240 61 11 59.[email protected], www.abb.com/hvdc