By Ariana Hurtado, Editor and Director of Special Reports

The four-day 2022 Offshore Northern Seas (ONS) conference provides an opportunity for industry executives and experts to network, discuss the future of the energy industry and explore new forms of leadership and business models, but the highlight of the show is the new technology.

ONS 2022, which features five conference venues and nine exhibition halls, is being held Aug. 29 to Sept. 1 in Stavanger, Norway.

The event is held every two years, bringing in 1,124 exhibitors in 2018 but was canceled in 2020 due to the COVID-19 pandemic.

“Both batteries, solar energy and other low-carbon and renewable energy sources will be presented and discussed at ONS 2022—and more than ever before—but not disconnected from the energy security situation and the work to reduce dependance on Russian gas,” the ONS conference page stated.

The conference will feature the president of Ukraine as a speaker at the opening ceremony on Aug. 29. President Volodomyr Zelenzkyy will join live by video-link from Kyiv. The opening of the meeting place for discussions on energy will be the second time Zelensky “visits” Norway, since addressing the Norwegian parliament in March.

Tesla and SpaceX CEO Elon Musk will be speaking at the official opening session at the ONS conference today. He will share his insights on current efforts with satellite communication systems in Ukraine and his thoughts on the energy industry.

Musk said on his Twitter page in March, “Hate to say it, but we need to increase oil and gas output immediately. Extraordinary times demand extraordinary measures.”

ONS will have a strong focus on how technology can be the key to unlocking offshore challenges, driving down costs, enhancing efficiency and growing sustainable production levels.

The following is a sampling of the new technologies and services being showcased at the conference this week that can benefit companies in their ongoing drive to efficiently find, develop and produce offshore reserves.

Editor’s note: The technology write-ups below have been contributed by ONS exhibitors and edited for clarity and style by Offshore.

Jacket lift system limits subsea work, safety challenges

Aft-mounted, the system comprises two structural beams, 170 m in the long configuration or 145 m in the short configuration (for shallow-water operations). The beams are connected at the top by a connection beam and hinged by means of an upend system and a derrick hoist system. Both beams are outfitted with three main hoists to lift jackets and modules.

Jackets can be rotated 90 degrees to facilitate the delivery of complete structures to shore for disposal and recycling, even in locations when a deepwater port is not available. The system also allows for the transport of jackets in a near-vertical position where necessary to safeguard structure integrity.

Superior lifting capability significantly reduces lengthy and weather-sensitive, complex subsea cutting operations, moving the work onshore where it is safer, less risk to the environment and more cost effective. Reduced operational time in the field, and the elimination of support vessels delivers substantial emissions savings.

Allseas spent more than two decades designing, developing and building the system, which complements the motion-compensated, bow-mounted topsides lift system.

It was used for the first time in April 2022 to remove the Ninian Northern jacket from the UK North Sea. Subsequently, in July to remove the Gyda jacket (pictured) from the Norwegian Sea and in August to install the DolWin Kappa wind converter platform offshore Germany.

Allseas Group (hall 2, booth 2400) will be present at ONS 2022.

Partners collaborate on offshore green hydrogen production concept

While the technology is ready, the green hydrogen sector has struggled to establish a sustainable commercial model so far. This solution provides an offtake for the electricity produced in the immediate vicinity of the wind farm and uses existing platforms, pipelines, terminal infrastructure and offshore equipment to reduce costs and produce more than 100 tonnes of hydrogen per day. This model allows green hydrogen projects to go pretty much anywhere offshore wind projects can.

The significance of this is that the green hydrogen industry can begin to do what the oil industry has done so well—go to where production is cheapest and export the product to wherever it’s needed, decoupling local supply from local demand.

Well planning digital tool improves efficiencies

Cognite Data Fusion provided effortless discovery of structured and unstructured subsurface well data in both time and depth, enabling their users to analyze and interpret historical events on the offset wells to be validated and reduce associated risks with well planning.

With Cognite Data Fusion, they contextualized engineering and subsurface data encompassing 10 global assets, including 25,000-plus wells and 2 million-plus documents. As a result, the supermajor gained significant efficiencies across the entire well delivery workflow.

Cognite (hall 8, booth 8200) will be present at ONS 2022.

Software offers drilling parameter optimization in real time

An automated drilling upgrade often requires a heavy and costly investment. eDrilling’s wellGuide is a software for real-time drilling parameter optimization. Making it available for E&P companies addresses the cost savings needed for field life extension, which is necessary to reach the industry's sustainability goals.

An edge system based on cloud technology combined with model-based reasoning in artificial intelligence provides real-time advice and what-ifs (forward-looking) for operational parameters within the limitations of the well. A key enabler is an automatic calibration of models for multiple what-ifs to find optimal drilling parameters. Testing of the edge system on multiple wells from several operators has been done both related to automatic calibration of real-time prediction models and for optimization of drilling parameters.

wellGuide increases operational performance, embraces and extends existing solutions, and as a result, lowers deployment costs.

eDrilling (hall 3, booth 3172) will be present at ONS 2022.

JV creates subsea pump development

According to the agreement, Equinor and Vår Energi will support the development and testing program with funding and end-user expertise. In return, they get to influence and gain early access to the technology.

FASTsubsea is a joint venture between FSubsea and Aker Solutions. The company combines the smart and powerful HydroMag and MultiBooster technologies from FSubsea and Aker Solutions respectively to create a highly robust and simple seal-less multiphase pump. The technology is seal-less, barrier fluid-less and does not need any electric variable speed drive.

The participation from Equinor and Vår Energi comes in addition to a NOK 11 million (US$1.1 million) commitment from the Research Council of Norway. The project is underway with low technical risk as all major components are individually qualified for subsea process use. Final system testing is scheduled to start in 2023.

According to Alexander Fuglesang, managing director of FASTsubsea, the FASTsubsea technology allows operators to more rapidly and effectively extract additional hydrocarbons from existing offshore wells and installed infrastructure. End users are drawn to the technology as increased recovery (IOR) now can be done in a much more environmentally friendly way, and at up to 50% lower investment (capex) than conventional subsea pumping systems.

FSubsea (hall 3, booth 3254) and Aker Solutions (hall 7, booth 7100) will be present at ONS 2022.

HAZOP assistant uses explainable AI technology for O&G industry

Kairos Technology’s HAZOP (hazard and operability) study was introduced almost 50 years ago, and it is still a work process that is of importance to identify and manage hazards. There have been many attempts to improve the HAZOP process, but it is still largely dependent on the level of experience in the participating team members.

The Kairos Technology approach is based on creating a "functional twin" of the process/asset that demonstrates how component failures (initiating events) may be detected and controlled to avoid process consequences. The models are based on the plant P&IDs and mass and energy balances. Based on the functional twin, Kairos can optimize the amount of instrumentation and map sensors versus failures; show how a failure propagates in the plant to become a hazard; and document (lack of) safeguards.

The first release of the software was May 2022.

Kairos Technology (hall 4, booth 4700) will be present at ONS 2022.

Valve provides leak reduction and elimination

The ES valve is certified as meeting the ISO 15848-1 Class A standard, providing assurances of leak reduction and elimination.

The priorities of the offshore and oil and gas industries remain the same: safety, reliability and cost reduction, but as the focus continues to shift toward reducing emissions, an approach to valve engineering can lead to a step change in performance in all of these areas.

Fugitive emissions from traditionally designed valves are significant contributors to climate change. By removing the stem from its axial control valve range, Oxford Flow has pioneered a product that can play a crucial role in tackling these emissions.

Bypass plugs for shallow- and deepwater

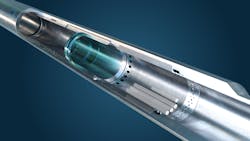

TCO, known for the creation of the laminated glass plug, has developed a new Deep Set Bypass Plug (DSBP).

TCO will offer two types of bypass plugs: its Disappearing Tubing Hanger Plug (DTHP) and the DSBP.

The DTHP is designed specifically for shallow applications. In comparison, the new DSBP has been developed to accommodate deeper applications.

A key feature of the DSBP is that it has a communication bellow, and this bellow has been incorporated to facilitate the need to be run in deepwater. The bellow also means that the DSBP can be run in mud applications and suspended for longer periods reducing the risk of debris affecting the functionality of the plug.

Similar to the DTHP, the DSBP offers an ISO 14998 VO certified barrier.

TCO (hall 8, booth 8410) will be present at ONS 2022.

Elastomer seals designed for HP/HT environments

The seals have two corrosion-resistant metallic anti-extrusion springs molded into the elastomer profile, which provide a rigid backbone and maintains flexibility. While the elastomer element maintains a gas-tight seal when unpressurized, the springs provide strong extrusion resistance, and during operation, they work with the pressure to increase the sealing effect. As system pressure increases, the anti-extrusion springs are forced into the extrusion gap, providing a robust and reliable seal. The springs facilitate high-pressure operation through a temperature range of -45 C to +260 C / -49 F to +500 F.

XploR S-Seal and XploR FS-Seal combine the benefits of integral support components with the flexibility of an elastomer seal in a single-piece, removing the need for multiple backup rings that require correct placement in a housing. This significantly simplifies installation in closed grooves and allows for several components to be consolidated into one.

Trelleborg Sealing Solutions Norway (hall 7, booth 7340) will be present at ONS 2022.

08.29.2022