Multi-purpose drill out/clean-up tool saves rig-time in Saudi Arabia

Lyndsay Harley, Coretrax

Drilling through cement, shoe tracks, and plug sets has traditionally been performed over multiple trips in hole. But the high volumes of debris created over each run can have a detrimental impact on the liner top packer.

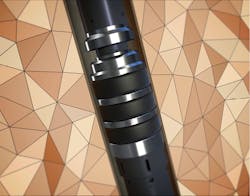

Coretrax’s CX-LTTT (HD) – Cement Drill Out device combines the drill out of cement, clean-up, displacement and inflow test operations in one run. It is an enhanced version of the company’s Liner Top Test Tool (CX-LTTT) which, along with non-rotating scrapers, brushes, magnets and circulating tools, provides assurance of the well construction prior to the completion being run. The device is designed for isolated negative inflow tests on liner tops and casing shoes and in tandem with other wellbore clean-up tools, can be deployed as part of a single-trip displacement run.

As a multi-set packer with three separate elements, it works by setting down weight to compress and extrude the elements. It can be used both during drilling operations and the displacement process. The large bypass area under the packer element enables quick running speeds.

To support a long-running wellbore clean-up contract offshore and onshore Saudi Arabia, the company developed the CX-LTTT (HD) as a heavier-duty, more robust tool for the operator that could also provide rig-time savings. It combines the cement drill out run with clean-up/inflow test procedures, eliminating the likelihood of an additional trip in hole. The tool is designed for all inflow test applications, including situations where there is a need for drilling through cement, plug sets, float collars and partial shoe tracks, and can be used to determine the integrity of the liner top prior to the next section being drilled.

Prior to inflow testing operations, conventional cement drill out activity involves removal of the cement, landing collars and float collars. While the CX-LTTT is a proven and reliable solution for these tasks, the heavy-duty (HD) version better addresses the challenges of longer drilling hours and the risks associated with circulating debris past the packer element. Following a fasttrack R&D program it was launched to market within three months. Experience to date shows it can deliver on average a 30-hour rig-time saving per well.

The tool is designed with a large concentric bypass that allows for quick running speeds and a generous flow area past the tool to achieve high flow rates, which are essential for recovering debris out of hole and minimizing risk of damage to the packer. It can also work across different metallurgies in the shoe track. Furthermore, the packer is designed with customizable shear value torque-through capabilities making it suited to a range of applications, including HP/HT, extended reach drilling, and multi-lateral projects, as well as being able to run in one trip. Essentially, the tool is a purpose-built packer added to the wellbore clean-up assembly to allow inflow testing to be performed concurrently in the harsh operating environments prevalent in Saudi Arabia. It can be set at depths of up to 17,500 ft (5,334 m) with a well inclination of around 74°. To date it has run up two years of successful operation and delivered strong results for the operator.During the initial three-month period of bringing the tool to market, Coretrax had successfully conducted eight inflow tests, of which seven were for cement drill out, the other being a conventional wellbore clean-up and inflow test. By combining the cement drill with use of the CX-LTTT (HD), around 480 hours (20 days) were saved providing a financial saving of $1.2 million. Although combining an inflow test packer with wellbore clean-up tools is not a new concept, what the client asked the company to drill out with these tools in the string was unconventional.

Historically, inflow test packers have been in the string when milling out cement. This application involved drilling through larger volumes of cement, rubber, aluminum, and other materials. Adding in larger pieces of debris made of different types of materials increased the risk of damaging the packer and therefore triggering a failure. So, Coretrax had to design a packer that was sufficiently robust to withstand the debris generated and yet still function as required after more than 30 hours of drilling. Previously operations in Saudi Arabia had been conducted over two trips as no packers were available that could deliver suitable results.

In early 2017, the CX-LTTT (HD) device was first run for cement drill out operations and inflow testing of a 7-in. 32# liner. The cement was tagged at 11,905 ft (3,628 m) MD and drilled out along with the landing collar and float collar to a depth of 12,291 ft (3,746 m) MD. Over a period of 12 hours, a total of 386 ft (117 m) was drilled.

The hole was circulated clean before landing on the 7-in. top of liner at 11,490 ft (3,502 m) and setting down 35,200 lb to shear and function the tool. Over a period of 10 minutes, a backside pressure test was performed at 1,000 psi (68.9 bar), confirming the tool’s integrity. The packer was then un-set and fresh water pumped to achieve a final drawdown pressure of 4,400 psi (303 bar). Set down with 30,000 lb, the pressure was then bled off in stages of 500 psi (34.5 bar) for an inflow test, plotted on a Horner graph in line with the operator’s procedures. Once confirmed as successful, a full displacement was conducted and operations continued as per program.

To date, the company has achieved 130 successful well runs, saving the operator more than 3,900 hours of rig-time and around $10.2 million in costs. Development of the technology continues, and the company has a strong pipeline of work for the HD version in the Middle East region, including projects in the UAE and Kuwait. •