LLOG deploys technologies in the Gulf of Mexico

Tom Bryce,Enpro Subsea

Subsea oiland gas infrastructure has developed significantly over the last 25 years, yet hydrocarbon recovery from subsea wells is still typically 20% less than topsides alternatives. It is an improving picture, with less complicated and more cost-effective solutions now increasing ultimate recovery and delivering first oil earlier. Many of these innovations are coming from specialist subsea organizations founded in Europe.

Standardization has become a common theme as the industry adjusts to a lower oil price. Operators have demanded low cost ‘standard hardware’ with shorter lead in times, which has long been a holy grail for the subsea industry. At best, this drive toward standardization often comes with a penalty of inflexibility and lack of strategic field development options.

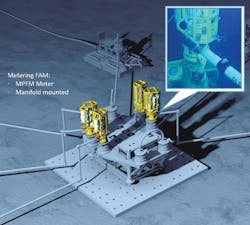

Flow access modules ready for deployment. (All images courtesy Enpro Subsea)

Alternatively, specifications which begin as low cost and simple, often increase in complexity and cost as they move through the project and many of the initial advantages are lost. These specification changes are often determined with limited field development or reservoir information. As a result, low cost basic ‘standard’ specifications typically evolve into higher cost multi-well specifications which attempt to address various potential field development needs in a single repeatable design.

This leaves operators with a choice of either adopting low-cost, fasttrack standard hardware with limited strategic options or project-specific hardware with corresponding price and delivery impacts.

Enpro Subsea has been working with operators globally to develop an alternative subsea hardware strategy, which it calls ‘smart standardization.’ This allows operators to ‘have their cake and eat it’, i.e. to maximize recovery from subsea wells by enabling production enhancing technologies to be fitted to standard OEM fasttracked hardware.

Delivering enhanced production

Technologies developed by Enpro Subsea, including Flow Access Modules (FAM) and Flow Intervention Services (FIS), have repeatedly delivered increased recovery, reduced costs, and earlier first oil in the UK, Gulf of Mexico, and West Africa.

The patented FAM technology is an enhanced subsea architecture which enables capital efficient flexible field development. It allows operators to place project-specific production technologies onto standard stock subsea hardware. It consists of a FAM ‘hub’ which is typically located within the jumper envelope and a FAM processing module which houses the production technology hardware, including meters, valves, pumps, and instrumentation.

The first FAM opportunity addressed a challenge facing an operator in the Gulf of Mexico in 2016. The operator wanted to connect a new subsea well into an existing subsea manifold and flow loop, via a single spur flowline 3.2-km (2-mi) tieback, in the Mississippi Canyon. The company was asked to propose a design for a fasttrack solution using the operator’s existing deepwater infrastructure and a surplus inventory of multi-vendor subsea hardware, in only a 12-month project deadline.

The well spud location, existing infrastructure, and established operating procedures in place created various potential ‘life of field’ issues for the company to consider in its design. This included a flow assurance strategy devised to overcome production chemistry issues and uneven seabed topography, and successfully manage and mitigate the potential for hydrate formation within the single spur flowline.

The operator also required multi-phase flow metering (MPFM) and water-cut metering (WCM) on the project to detect water breakthrough, which would influence the flow assurance strategy. The MPFM would also enable the production engineers to use the instantaneous flow rates to optimize and maximize production out of the individual well.

Fluid intervention capability was also requested by the operator, to allow hydraulic intervention and well stimulation operations into either the pipeline or the reservoir in later field life to enable maximized recovery from the asset.

The solution delivered by Enpro used the patented FAM hub at either end of the flowline providing chemical injection opportunities at both ends to a manage hydrate issues as required, eliminating the need for an additional ‘loop’ or return line. The operator additionally installed a semi-permanent FAM metering module at the tree end of the flowline and a FAM hydraulic intervention was available to be deployed in the future.

Dual FAM on either end of a 3.2-km single spur flowline tieback.

Notable milestones

In 2017, LLOG selected the FAM technology as it fully aligned with its strategic approach to fasttrack, capital efficient subsea tiebacks. The company adopted FAM on multiple fields including Crown & Anchor, Red Zinger, and Stonefly, and they will be deployed on 12 wells by the end of 2018. FAM is initially being used to enable retrievable multi-phase metering located within the jumper envelope between the tree and the pipeline end manifold or pipeline end termination. The same FAM can be used for other enhanced production solutions in the future, including water cut metering, flow assurance, hydraulic intervention and fluid sampling, providing the operator the chance to defer capex and address specific reservoir needs in the future.

To date, 42 FAMs have been adopted globally in 11 fields and three deepwater regions.

Metering FAM on a manifold.

Making future decisions

De-coupling the procurement of the main subsea hardware means that all ‘life of field’ engineering can be completed concurrently and therefore not negatively impact the robust fasttrack schedules of the standard equipment. The FAM hub within the jumper envelope essentially becomes a subsea ‘USB’ port, through which multiple enhanced production technologies can be deployed. The individual modules can be used (and reused) independently, in series or in combination to support various production optimization strategies. Some FAMs are deployed with just a ‘flow thru’ module, where the operator does not yet fully understand what strategies may be needed in the future but still wants a low cost ‘USB port’ in the infrastructure to facilitate future solutions, as a contingency.

In addition to FAM technology being used in multiple greenfield opportunities in the GoM, it has also been used in brownfield applications in West Africa and the North Sea, where FAM was retrofitted into existing subsea infrastructure.

Enpro’s focus on the future is to further reduce the cost of the FAM module to enable its universal adoption on all subsea architecture. Additionally, the company is extending the range of processing solutions which can be enabled by the FAM technology, specifically in pre-commissioning, single well multi-phase pumping, and HIPPS.

The company hopes to repeat the success of FAM in the Gulf of Mexico in other parts of the world and is seeing significant interest from Brazil, following recent promotion at Rio Oil & Gas. •