Gene Kliewer • Houston

World’s deepest multi-phase pump project starts

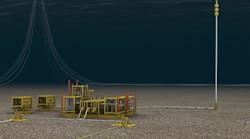

BP has a successful start-up of the world’s deepest subsea multi-phase pump project at the King field in the Gulf of Mexico. The project, which has two subsea pumps and associated equipment, also sets a distance record.

At 5,500 ft (1,676 m) water depth, King almost doubles the previous record subsea multi-phase pump project depth and, at 15 mi (24 km) from theMarlin TLP is more than twice the distance from its host platform.

BP says the project is expected to increase production from King field by 20% and increase its total recovery by 7%, thereby extending the economic life of the field by five years. King is in Mississippi Canyon block 84. TheMarlin TLP is 75 mi (121 km) offshore Louisiana in Viosca Knoll block 915.

“In line with our strategy to maximize reserves from out existing fields, the application of this cutting edge technology across BP’s large deepwater portfolio has the potential to unlock significant resources that would otherwise remain unrecoverable,” says Andy Inglis, BP’s chief executive of E&P.

New technologies applied at King include:

- A long-distance, high-voltage distribution system to control multiple pumps at different speeds using variable-speed drive systems to avoid interference within an umbilical and to simplify the connections

- The umbilicals linking the pumps to the host platform were developed as self-contained delivery lines for hydraulic fluid, chemical feeds, and lube oil

- The umbilicals also house a new fiber-optic communication system for quick pump response.

Each pump station is on a suction pile with the pump inside a manifold.

Aker Kværner supplied the subsea pumps and installation. Nexans supplied the umbilical. Installation was by Saipem and AMC.

Subsea wireline intervention system in development

Development and commercialization of a lightweight subsea wireline intervention system is under way at Expro International Group Plc. and BP Exploration Operating Co. Ltd.

Expro will build and deploy a fully engineered AX-S system; BP will provide partial project funding and technical input, including field trials of the AX-S system on subsea wells. These field trials are scheduled for the first half of 2009. The AX-S system aims to extend the limits of lightweight intervention to water depths of up to 10,000 ft (3,048 m).

“The road to commercialization can be lengthy and extremely expensive,” says Graeme Coutts, CEO of Expro. “I am therefore delighted that we have been able to construct a contractual relationship which reflects full strategic alignment between technology provider and end user.”

FMC to supply Åsgard subsea controls

FMC Technologies Inc. has won a $35-million contract to supply subsea gas compression control systems to StatoilHydro for the North Sea Åsgard Minimum Flow Project.

FMC will supply a subsea active magnetic bearing control system for the compressor in cooperation with Waukesha Bearings and a subsea anti-surge actuator and valve. FMC also will develop and implement new sensor technology for the system.

“We have a strong history of subsea technological successes,” says John Gremp, executive vice president of FMC Technologies, “and the development of these components is another very important milestone in addressing future subsea compression needs in the industry. We are excited to assist StatoilHydro in this next step of subsea technology development.”

New pipeline inspection tool

The AGR Group’sNeptune is a new pipeline inspection tool that operates on an inspection ROV without diver assist. This serves to extend the depths of operation to about 6,000 m (19,685 ft), or the maximum for the ROV.

The tool itself is a high-resolution ultrasonic imaging tool and the first of its kind to do both wall thickness mapping and time of flight diffraction wells inspection. The AGRNeptune data is digitized and transmitted via the ROV umbilical.

“With increasing life of fields, a global emphasis on HSE best practice and the increasing demands placed on subsea infrastructure, new solutions to ensure integrity are required,” says Age Landro, executive vice president of Field Operations for AGR. “The AGR Neptune helps answer that demand. It is also rewarding to bring a technology to market that is both cost saving technology and reduces personnel risk.”

BP signs global service contract with Intec

BP has awarded a global Engineering and Project Management Services agreement to Intec Engineering covering subsea facility projects over six years. According to the agreement, Intec will provide call-off supply of services tailored to the specific project.

“We are very pleased to continue to support BP’s challenging subsea requirements around the world,” said Uri Nooteboom, Intec vice president for Field Development Projects. “This important long-term relationship represents the opportunity to deliver continuous improvement in the design of BP’s subsea systems and continuous opportunity for our world-wide staff,” said Nooteboom.