Alex Boheimer - DeepSea Engineering

Engineering analysis that supports a balanced design approach, and covers the entire project life cycle from design to operation, can give independents increased flexibility and added foresight, yielding better project outcomes with increased profitability.

Higher oil prices and, in some regions, government encouragement, are fomenting increased activity among independent exploration and production companies in regions from the Gulf of Mexico to the North Sea, West Africa, and Southeast Asia. Independents need to control their level of exposure in the marginal fields in these regions. In particular, a smooth installation campaign is essential, as this is one of the highest cost components of a project.

Independents face specific issues in field development, notably optimizing costs, selecting available technology (as funding research and development of their own is not usually an option), and dealing with infrastructure, levels of local access, content, and capability. Building in flexibility for extension later – with minimal disruption – is often an additional requirement. Meanwhile, in common with their larger competitors, independents face an industry-wide shortage of skilled personnel.

Design benefits

A number of benefits result from designing for installation. First, it is necessary to obtain and to understand the reservoir’s characteristics, including the water depth, climate and environmental factors, geology, etc. With this information and a subsequent well intervention strategy, greater flexibility is given with respect to the vessels and other hardware needed to install the subsea components. This helps to use what is actually available in the current high-demand market. Also, determining the likely well intervention strategy at an early stage dictates the type and level of installation required. For example, in some cases, early subsea intervention strategy may lead to the selection of horizontal trees for development. This type of tree can be installed by vessels other than the drilling unit. Another subsea development scenario that may be derived from early design for installation and intervention includes multiple satellite or cluster wells situated around small manifolds. This approach optimizes procurement opportunities and manages cashflow efficiently by offering the prospect of smaller, cloned structures installed by a wider choice of vessels.

For one client, DeepSea formulated the idea of de-coupling an 1,800-m (5,905-ft) dredging riser. The results were:

- Lower cost and lower risk with no moon pool in the vessel

- Reduced complication and cost of riser tensioning system

- Increased flexibility during the installation campaign as deployment of the riser became independent from the vessel

- Wider variety of locations for fabrication of the riser

- Simplified relocation of the riser throughout the field.

Innovative thinking is required to plan the development of new fields since each possesses unique characteristics. Advanced engineering skills combined with a common sense approach enable independents to get the job done properly, on time, and to budget. For example, installation limitations such as the lack of an available heavy-lift vessel can be overcome by designing and commissioning lightweight subsea structures. The additional upfront cost required is more than offset by reducing installation cost and bringing forward first oil.

Lightweight mid-water arch designed for installation by limited lift capacity vessel.

In one example, DeepSea was contracted by an independent company to design a riser system supported by a mid-water arch for 100 m (328 ft) water depth offshore Brazil. The arch was designed to accommodate a very low weight limit (150 metric tons [165 tons]) to allow for a greater choice of installation options. This design involved a slightly higher upfront investment in engineering design, to be offset by the lower cost of installation.

The structure was designed with tubular members and buoyancy tanks with lighter gauge materials, stiffening plates, and additional compartments, to reduce its weight. This concept was supported through the detailed design and procurement stages, to ensure that the structure was fabricated correctly.

Other cost-effective elements of field development solutions include the use of flexible risers with FPSOs (e.g. with hurricanes and cyclones to be considered in the design configuration), application of reeled systems, and wet towing.

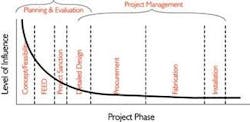

It is far easier to manage risk effectively if it addressed early in a project. If not, risk increases as the project progresses. And by the time the detailed design phase of a project starts, typically it is too late to make major changes to the development plan.

Changing from a “design for operation” to a “design for program life” mindset gives companies, particularly independents, the fuel to better manage risk to maximize field development profitability.

About the author

Alex Boheimer is Europe business manager for DeepSea. Previously at DeepSea he has managed projects in Gulf of Mexico, North Sea, and West Africa. He also has worked in the auto industry where he was a specialist in new combustion technologies.