Gene Kliewer • Houston

StatoilHydro conducts first ever full-scale subsea compression test

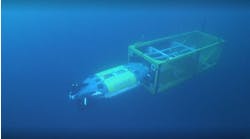

The world’s first full-scale subsea compression test was held recently at StatoilHydro’s Kårstø Laboratory.

The facility can analyze, test, and qualify several types of full-size gas processing equipment, including subsea compressors and pumps, high-pressure separation units, multiphase meters, values and pipeline pigs, says Trond Austrheim, lab manager.

The facility was upgraded to the tune of NOK250 million ($49 million) to evaluate subsea gas compression as a method to boost gas production from Midgard and Mikkell for Åsgard/Middel License Partners -- StatoilHydro, ExxonMobil, Total, Eni, and Petror.

Compressor prototypes from MAN Turbo and Siemens are to be tested at the facility over two years. The MAN unit already is installed, and the Siemens unit is scheduled to be ready for trial in 2009.

“Åsgard is in many ways tailor made as a front runner for qualification of subsea compression as the compressor unit on the seabed will serve a number of wells and thus distribute the cost for qualification on a large gas volume,” says Rolv Herfjord, StatoilHydro Åsgard Minimum Flow Project manager. “In addition, the motor drive (frequency converter) can be located on the Åsgard B platform, where the water depth is familiar.”

Contracts awarded

VetcoGray, a GE Oil & Gas business, has won a five-year frame agreement to supply subsea equipment and support services for the Gorgon Project.

The scope of VetcoGray’s contract includes the supply of manifolds, pipeline termination structures, pipeline end terminations, trees with subsea control modules, wellheads, production control systems, system integration testing, installation, and operations support.

The schedule for the supply and delivery of the equipment is to be developed.

The project includes the subsea development of the Greater Gorgon natural gas fields, about 130 km (81 mi) off the northwest coast of Western Australia in 200-1,300-m (656-4,265- ft) water depths between 65-134 km (40-83 mi) from Barrow Island.

The fields will be linked to a three-train, 15 million ton (13.6 million metric ton) per year LNG facility, with provision for domestic gas production on Barrow Island. Chevron Australia Pty Ltd. of Perth is 50% owner and operator of the Gorgon Project in a joint venture with the Australian subsidiaries of ExxonMobil and Shell.

StatoilHydro has awarded FMC Technologies a $50-million contract for Yttergryta development. The contract covers a horizontal subsea tree system, flow control module, choke, tubing hanger, flow base, umbilical, and monitoring and testing hardware.

Installation at Yttergryta, a gas field 3 mi (5 km) northwest of Åsgard B in the Norwegian Sea, is expected to start this year.

Acergy SA has won a $50-million contract to fabricate, assemble, and test eight manifolds and support structures, eight suction piles, 23 well jumpers, and other subsea structures for Usan oilfield off Nigeria for Cameron Offshore Systems Nigeria Ltd. Work will be done at Acergy’s Globestar Yard in Warri, Nigeria.

Angel gets topsides

Working for Clough Aker on behalf of Woodside Energy Ltd., the DockwiseBlack Marlin heavy-lift vessel has installed the 7,300-metric ton (8,047-ton) Angel platform topsides off the North West Shelf of Australia. The float-over installation was fitted to a four-leg, steel jacket in 80 m (262 ft) of water. McDermott’s Intermac 650 installed the jacket. The Angel platform is to be tied to three subsea satellite wells and will be capable of processing 800 MMcf/d of natural gas. The gas will be exported in a 50-km (31-mi), 30-in. (76-cm) line tied to the North West Shelf first trunkline. First gas is expected in 4Q 2008. Woodside operates the Angel gas project on behalf of BP Developments Australia Pty Ltd., Japan Australia LNG (MIMI) Pty Ltd., BHP Billiton Petroleum (NWS) Pty Ltd., Chevron Texaco Australia Pty Ltd., and Shell Development (Australia) Pty Ltd.

null

Songa buys EVO BOP

Songa Offshore ASA has awarded Cameron a contract for an EVO subsea BOP stack, subsea controls, drilling riser, and choke manifold. Songa has a contract with Odjfell Rig Ltd. to acquire the semisubmersibleDeepsea Trym in 2009. Among the modifications scheduled to be made to the rig is the addition of the Cameron EVO drilling system. The rig currently is working for StatoilHydro.

null