For the fourth year running, the Offshore Technology Conference (OTC) has recognized individual companies for their innovative technologies with the Spotlight on New Technology award.

The 14 winners were honored at the Spotlight on New Technology presentation on the afternoon of April 30, the first day of the 2007 OTC. The event took place in the rotunda in Reliant Center.

OTC selected the winning technologies on the basis of four criteria:

- New and innovative: The technology must be less than two years old

- Proven: The technology must be proven, either through full-scale application or successful prototype testing

- Broad interest: The technology must have a broad interest and appeal to the industry

- Significant impact: The technology must provide significant benefits beyond existing technologies.

Aker Kvaerner Subsea: SeaBooster

Aker Kvaerner’s SeaBooster system increases the production rate of oil wells requiring local pressure support by injecting sea water. The system allows the water injection system to be located close to the actual wells, avoiding installation of expensive flow lines and topside water injection pump at a host platform.

The SeaBooster system can handle flow rates up to 151,000 b/d and can generate differential pressures up to 4,100 psi for both fracture and continuous pressure support modes of operation. The system includes a filtration module for subsea solids removal prior to injection into the reservoir to avoid plugging the formation, as well as provisions for chemical injection to prevent reservoir souring. The SeaBooster is driven by a proven freshwater/glycol-filled electric motor supplied to Aker Kvaerner Subsea by Hayward Tyler. The water-filled motor used with the SeaBooster system provides the necessary pressure monitoring and simplifies maintenance.

Aker Kvaerner Well Service: PowerTrac Cone Crusher scale mill concept

The Cone Crusher scale mill tool answers the problem of removing wellbore scale build-up. The Cone Crusher assembly, run in conjunction with the PowerTrac Advance (PTA) wireline tractor, is set up with a special rotation adapter, mill gear, and shock absorber for weight-on-bit control.

The PTA tractor wheel section can be used as an anchoring device in vertical sections and an anchoring and forward thrust device in horizontal sections of the well. The Cone Crusher technology is based on a robust design where a main body with four cutting cones are rotating. Each cutting cone is free-rotating in its own axis, independent of the main body RPM. Each cone has a unique cutting pattern that crushes the scale, allowing the flow of oil or gas to resume. The Cone Crusher scale mill tool is a valuable tool for scale removal, especially in extended-reach and horizontal wells and can be a cost-effective alternative to coiled tubing services.

Baker Oil Tools: Diamond Fraq polymer-free high-performance fracturing fluid

Diamond Fraq is the first VES fluid with polymeric fracturing fluid performance properties and superior formation and proppant pack cleanup capability. Its micelle stabilizers extend VES fluid use to 300° F (148.8° C). Viscosity enhancers reduce VES loading, and fluid loss control agents significantly reduce fluid leakoff to at least 2000 md and 250° F (121° C) to reduce fluid treatment volume and improve fracture geometry. Diamond Fraq uses nano particle technology to:

- Associate (pseudo-crosslink) VES micelles together

- Stabilize VES micelle structures to 300° F (148.8° C)

- Form a pseudo-filter cake composed of highly viscous VES fluid (micelles) and nano particles.

Internal breakers work over a wide mix water salinity and temperature range to:

- Go wherever the VES fluid goes to assure viscosity reductions

- Eliminate reliance on reservoir hydrocarbons to clean up VES fluid

- Work synergistically with high-temperature stabilizers, viscosity enhancers, and fluid loss control agents.

Baker Oil Tools: linEXX solid expandable monobore liner extension system

The linEXX solid expandable monobore liner extension system optimizes casing configurations for drilling deeper or for isolating trouble zones without reducing critical hole size.

The system consists of:

- RC9 series recess casing shoe

- FORMlock expandable liner hanger/packer

- linEXX solid expandable casing

- RNX retrievable guide shoe

- catEXX hydraulic, top-down expansion system.

DYNAenergetic GmbH & Co. KG: No debris gun system

Perforating jobs traditionally leave a lot of unwanted debris in the well because the interior of the perforation guns and the cases of the shaped charges are fragmented during the shot. To overcome this situation DYNAenergetics GmbH & Co KG has developed a new type of perforating gun system. The no-debris gun (NDG) system leaves no debris in the well because the shot holes in the gun close after the shot. This is achieved by an internal sliding sleeve.

Tests with the NDG made in accordance with the new API RP 19b Section V standard have proven that no debris exits the gun during or after the shot. The NDG can be used with any standard shaped charge independent of size, geometry, or explosive type. QC shots with shaped charges in an NDG setup have shown little or no penetration loss.

FARO Technologies: FARO TrackArm

Faro’s portable computerized measurement devices replace hand tools and large expensive fixed coordinate measuring machines (CMMs). The FARO TrackArm combines technology from two top-selling portable CMMs - the FaroArm and FARO Laser Tracker - to measure geometric features and directly import 3D measurements into digital form for CAD model or part size verification. The FaroArm uses optical encoders, advanced error coding, and temperature compensation technology to record 3D points on items ranging from palm-sized to 12 ft (3.7 m). The Faro Laser Tracker X uses laser targets and Xtreme ADM technology to measure items up to 230 ft (70 m). TrackArm users can seamlessly move between the tracker and arm by using a laser target mounted directly on the FaroArm. This enables the user to measure in large volumes with the FARO Laser Tracker and then switch to the FaroArm to digitize areas hidden from the Tracker’s line of sight. CAM2 Measure, a shared software platform, collects all of the data in the same job file.

Halliburton: The Honey Comb Base tank system

The Honey Comb Base bulk cutting storage tank can improve safety and efficiency by eliminating the need for cutting boxes, associated cranes lifts, and the safety risks encountered in the process of handling cutting boxes. The system also frees up valuable deck space. The HCB tank system can provide a reliable, simplified transfer and storage option that can be easily installed and does not require proximity to the solids control equipment to function efficiently.

The air-operated SupaVac transfer system can vacuum drill cuttings up to 50 m (165 ft) and pump up to 20 tons per hour of drill cuttings 150-200 m (490-650 ft). The HCB tank discharges cuttings over long distances, at 48 tons/hr horizontally and 30 tons/hr vertically.

Jet-Lube, Inc.: Seal-Guard ECF and NCS-30 ECF

The Jet-Lube Inc. patented ECF technology complies with the stringent North Sea environmental guidelines for offshore chemicals while maintaining the required performance standards. Jet-Lube’s Seal-Guard ECF thread compound for premium casing and tubing connections and NCS-30 ECF thread compound for drillstring connections meet Norway’s “Yellow” standards and the UK’s “E” classification. The standards require pipe compounds to be biodegradable, bioaccumulation-potential-free, and nontoxic.

Both ECF compounds are entirely nonmetallic, yet provide excellent protection against seizing and galling. They are temperature rated for applications -54°C (-65°F) to 260°C (500°F), and their nonconductive formulas are ideal for high-pH mud (9-10%) applications. Seal-Guard ECF has been specifically formulated for use on premium connections. NCS-30 ECF was formulated for use on rotary shouldered connections, high-torque, and high-chrome or nickel alloys.

Modec International LLC: Moses self stable integrated platform (SSIP) tension leg platform (TLP)

The Moses SSIP is a TLP with inherent stability that allows quayside integration and commissioning of the topsides to the hull structure and wet towing of the integrated platform to the installation site. The TLP does not need expensive temporary buoyancy or craned assisted installation. The hull configuration comprises a central base structure, four tendon support structures (TSSs) and four vertical columns. The base and TSS structures are deep below the surface and provide a significant portion of the platform’s buoyancy. Each TSS is a rectangular pontoon structure. The rectangular columns are located further outboard and are smaller than conventional TLP columns. Eight tendons are supported at the end of the TSS (two at each end) via top connectors on a porch arrangement. The tendons are connected at the sea bottom on piles via bottom connectors.

The Moses SSIP TLP can support a variety of drilling or workover rigs and a large number of top tension risers and flowline risers. The Moses SSIP TLP can be used with wet and/or dry trees in harsh and mild environments.

Single Buoy Moorings Inc.: LNG toroidal swivel

Future LNG transfer with weathervaning offshore LNG terminals is now feasible. SBM has completed an in-house, three-year development program for the world’s first LNG toroidal swivel. The swivel, with its central opening, is a key requirement for marine transportation systems where LNG has been transferred for import or export through a weathervaning system. The design can be configured to allow the passage of multiple LNG streams up to 20 in. and a 16-in. vapor return.

The composite material bearings and the use of thermal rods inside the toroid shield the swivel sealing function from thermal deformations when cooled to -165°C (-265°F) operating temperature and 10.5 bar pressure. The swivel has undergone extensive test simulating over five years of continuous service and is in the process of receiving approval in principle from the American Bureau of Shipping.

Secure Drilling: The Secure Drilling System

The Secure Drilling System is a closed-loop system that analyzes drilling data to detect kicks or losses and automatically manages backpressure at the surface to control influxes or losses. The system allows volumes to be kept as small as possible - a micro-influx or micro-outflux. The system is designed to incorporate existing drilling and pressure control equipment with minimal upgrades and equipment additions.

In its most basic form, the Secure Drilling System allows the Driller to “see” on screen real-time changes in, and deviations from, expected behavior in flow and pressures. The driller can use the technology to interpret these changes and effect control on the situation through computer-controlled equipment that makes adjustments in the flow regime in response to the changes in downhole or surface conditions.

The Secure Drilling System allows overbalanced, near balanced, or underbalanced drilling and enables each section of the well to be optimized based on specific downhole conditions.

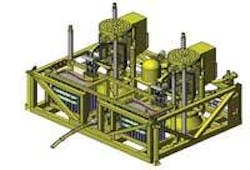

Versabar, Inc.: Versabar Deck Raising System

The systems used to raise the two eight-leg platforms employ 32 synchronously controlled, 260-ton hydraulic cylinders to lift the platforms 14 feet (4.3 m) each. The cylinders pin into lower padeyes welded to the existing legs and upper padeyes integral to the split extension sleeve. The 40 1/2 in. diameter, 1 1/2 in. wall extension sleeves capture the legs during the final leg cuts and with the rub rails, limit lateral movement during raising to 1/4 in. The legs are cut between two bushings installed near the top of the legs. Prior to the lift, the top of the extension sleeve is welded to the upper bushing, and after rising, the bottom of the extension sleeve is welded to the lower bushing. A twelve inch diameter, 1-3/4 in. wall pin inserts into the leg to provide a storm safe condition at all times except when removed to raise the platforms.

Vetco Gray: MR-6H SE marine riser connection

The Vetco Gray MR-6H SE marine riser system brings improvements to the current industry offerings in both safety and efficiency. The innovative design of the MR-6H SE combines field-proven technology of the H-4 subsea wellhead connector and the dog-style marine riser (MR-). To make the fully-automated connection of the MR-6H SE, hydraulic units on the spider engage a cam ring on the box which actuates six dogs into the profile in the pin. This creates a full pre-loaded connection with an efficient and effective load path.

Because the MR-6H SE connection is fully automated, people are taken out of a potentially hazardous situation.

The pin is lowered into the box and guided into place with an internal guide pin. Then the spider does the rest, automatically making up the connection. It takes less than a minute to make/break the MR-6H SE connection. A string of MR-6H SE can be run in about half the time of a flanged riser system

Weatherford: OverDrive system

The Weatherford OverDrive system enhances the safety and efficiency of top-drive casing running and drilling operations. Among the system’s primary components are the TorkDrive heavy duty and modular tools, which are mounted directly to the rig’s top drive for making up and breaking out casing. These tools provide complete casing running and drilling capabilities, combining the functions of conventional power tongs, bails, elevators, thread compensators, and fill-up circulation tools.

The OverDrive system provides faster makeup and breakout than conventional methods with accurate thread compensation, the ability to switch between fill-up and circulating functions without repositioning the tool, high-volume circulation and fluid recovery, independent torque measurement, and reduced risk of operator errors with multiple safety interlocks.

The system takes operations to a new level by providing the ability to do what conventional tools cannot. Advantages include rotating and pushing down the casing while running to help prevent differential sticking, achieving high-speed string rotation with the top drive when drilling/reaming-with-casing, and removing even more personnel from hazardous rig floor operations.

Other OTC technology ...

Cameron integrates subsea processing capabilities

Cameron announced the integration of its subsea processing capabilities into Camforce Subsea Processing Systems at the Offshore Technology Conference. The integration includes Cameron’s core subsea capabilities plus its research and development, plus technology added via acquisitions and partnering.

“This is a new initiative” for Cameron, said John Carne, president of the Drilling Production Services Group. In includes the core technologies of trees, valves, control chokes plus research and development products such as CameronDC, and partnerships and acquisitions providing power distribution, motors, flowline access technology, he said.

Subsea boosting is partnering in a joint venture with Curtiss-Wright EMD and its electro-mechanical technologies and equipment. Curtis-Wright brings with it a partnership with Leistritz and its twin-screw multiphase pump.

Through Cameron’s Petreco Process Systems Division, Camforce includes custom-engineering packages for separation, filtering, and treatment of oil, gas, produced water, and solids. Petreco technology drives the two-phase, all electric separation unit.

Most recently, Cameron acquired DES Operations Ltd. with its production enhancement technology including the Multiple Application Re-injection System to allow installation of multiple processing technologies directly into the subsea completion.