Statoil introduces new repair capability for offshore pipelines

Jan Olav Berge

Statoil

On behalf of the Pipeline Repair and Subsea Intervention (PRSI) Pool in Norway, Statoil recently completed the development of a new pipeline repair technology. This new system uses a welding robot as the primary method of repair for subsea pipelines larger than 30-in. and in water depths up to to 1,300 m (4,265 ft).

After several years of development, Statoil completed the new equipment's qualification process through underwater tests at depths of 400 m (1,312 ft) and 1,000 m (3,280 ft) in October 2014, demonstrating the equipment is ready for operation.

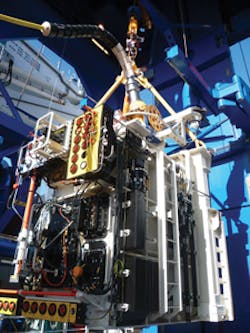

The new remote welding system is comprised of three main modules performing the pipeline joining process subsea: the remote welding habitat, the remote welding power and control (POCO), and the remote welding tool.

The remote welding habitat provides a dry, gas-filled habitat for the welding operation. A claw system supports and stabilizes the pipes to achieve good alignment and to ensure no relative movements between the pipe ends during the first phase of the welding operation. The habitat contains a pipe sealing door at each end to provide a gas-tight sealing system around the pipe entrance into the habitat. It also features a sliding side door which closes and opens for the entrance of the remote welding tool from the POCO.

The remote welding POCO is a separate module that contains all power and control function to support the welding operations, and provides dry storage of the remote welding tool during launch and recovery through the water column.

This module contains the most critical and vulnerable systems, and the option to recover this module separate from the larger remote welding habitat and the pipe preparation and positioning gives increased flexibility and improves the overall efficiency of deepwater operations. The remote welding POCO is permanently connected to surface via an umbilical and is gas filled with 0.4 bar overpressure relative to ambient pressure.

The last module is the remote welding tool, which is a specially designed "robot" containing all essential functions for the welding operation. It features a welding head with MIG welding torch and tip changer and is welding wire consumable. It has an induction heating system for sleeve and pipe joint drying and heating. Additionally, it has a survey head for close visual inspection, and a service head for light grinding and rework.

The three modules form the remote welding system and are parts in the total remote welding spread, which also includes tools for all preparatory work. This includes the coating removal unit (CRU), weld seam removal tool, hydraulic lifting frames (3 to 4 H- frames needed in the operation), pipe cutting tool, welding pigs and insertion tool, and pipe alignment and monitoring system.

The tools are all operational in the PRSI Pool and are commonly used for pipeline tie-ins and repair independent of the pipe joining process.

Operations

The remote welding habitat is first installed by means of the vessel crane. During this stage, pipe ends are prepared by removing all external coating, cutting to length, and installing welding pigs in each pipe end to create the barrier toward the gas pocket in the habitat. After landing the habitat on the seabed, the pipe ends are lifted into the habitat and secured by the pipe claws. The pipe doors are closed as well as the side door. The habitat closure is then filled with argon gas (blow-down), and the inert atmosphere dehumidified in order to establish acceptable environmental conditions for the welding process.

The operation's second stage is to launch the remote welding POCO. For this, either an A-frame launch and recovery system is used over the vessel side or a module-handling tower is used through the vessel moonpool. The enclosure is kept at a constant gas overpressure of 0.4 bars in order to secure no water ingress into the electrical systems and the welding tool and consumables. The POCO is landed on the habitat side platform and engaged on the connection interface. After verifying the interface seals are tight, the connection system is dewatered and opened to allow the remote welding tool to enter the habitat, the tool is driven to the pipe, and the pre-heat bands are closed and engaged around the pipe.

The preheat system then heats the pipe to a specified temperature and the welding path is learned and logged by the welding tool. Afterwards, the pre-programmed welding sequence is performed under supervision and control by a welding operator and a welding engineer. Acceptance of weld quality is based on a process-monitoring quality control system using predetermined ranges for all essential welding parameters. All parameters within the so-called green zone means an accepted weld, while deviations need to be assessed and. In the worst case, the non-accepted portion of the weld pass has to be ground away by the on-board service head grinding tool.

At this point, the equipment has been built, qualified and is now, in contingency, ready for use. During the qualification program, water trials were performed at around 400 m (1,312 ft) and 1,000 m (3,280 ft) with multiple dives to verify the equipment performance and the weld quality.

An important part of the remote welding system was to develop a suitable pipeline repair strategy and method of joining the pipe ends together. Traditionally, pipeline welding is performed by a butt weld joining technique, i.e. welding the abutting pipe ends by a full through wall thickness weld. In an automated system, this technique reveals several challenges, and this was the main reason for choosing a sleeve welding repair technique that is less demanding at this phase of development.

The oversize thick wall sleeve is pre-welded to each end of the repair spool during onshore fabrication, while the final weld between the sleeve and pipeline is performed subsea, inside the dry habitat. The fillet type of weld is designed to the actual strength requirement, and in reality over dimensioned in order to distribute the stress concentration into the highly utilized pipe wall outside the weld sector. Since this type of weld inherently has a crack-like defect in the root region, the design of the weld is based on a conservative full circumference weld defect of a conservative size and a potential crack growth through 50 years lifetime of operational cycles.

The equipment developed is the first step in a continuing development for increased capacity, application range, and water depths for remote repair technology. The present system limitations are strongly related to the current needs of the sponsor group: such as pipeline diameters ranging from 30-in. to 42-in. and water depths from 180 to 1,300 m (590 to 4,265 ft). It is anticipated that these will be extended in the future.

Looking ahead

Three main development areas are foreseen. One area is to encompass smaller diameter pipeline; another is to extend the water depth capacity both in shallower and deeper waters; and lastly, to develop a welding technique allowing repair of clad or lined pipelines. Future developments will be decided based on the need of the PRSI Pool members.

Expanding the remote welding system to smaller-sized pipelines will most likely be done in two steps. The current system may be modified to accommodate down to 24-in. pipelines relatively easily by simple geometrical modifications. However, in order to expand the diameter range to cover pipelines from 10-in. to 24-in., a slight adjustment to concept is required.

Increasing capacity for deeper water depths down to 2,500 to 3,500 m (8,202 to 11,482 ft), based on experience to date, is best solved by a new concept for gas and performance optimization and a development project is foreseen to capture such possibilities.

Another application area where remote-controlled technology may be beneficial is in shallow water, ranging typically from 10 to 20 m (32 to 65 ft). This is a depth range where diver-assisted operations are very demanding and resource intensive. Studies examining how the new remote welding system could be utilized for this depth range are ongoing and could well result in further developments and new application opportunities.

Finally, the new remote welding system may be applied on bi-metallic materials as for repair of clad or lined pipelines. This capacity requires further development of the welding technique while the basis technology and system is the same.

A hyperbaric- welded repair is superior to any mechanical repair due to its lifetime, reliability and pipeline integrity. PRSI intends to continue development of this technology for new applications in the future. •