Process control, asset management stand to gain

David Newman

Emerson Process Management

Vincent Vieugue

Roxar

Whether it is smart wireless platforms or continuous downhole information monitoring, effective process control and asset management is all about taking greater control over the production process.

An important way to achieve this is through developing a “central nervous system” for offshore operations to give greater predictability in operations and production, more efficient use of people, and to improve reservoir performance.

As oil and gas demand outstrips supply and with world energy use expected to increase by 45% between 2008 and 2030, offshore operators are under increased pressure not only to go deeper to find new plays, but also to ensure existing fields operate at peak potential.

In addition, much of today’s offshore operations take place against the backdrop of continued economic uncertainty, fluctuating oil and gas prices, frozen capital markets, and a focus on managing risk and reducing costs.

It is an important time to develop effective production strategies to accelerate cash flow, to enhance oil recovery rates, and to ensure each well operates at the peak of its capabilities.

Often, however, the technologies which help operators optimize production and manage costs are viewed as commodities rather than vital contributors.

Costs for process control and asset management, for example, today typically amount to just 3-5% of total project costs. Furthermore, the decisions operators make about process control strategies and technologies too often are made after the project is under way and after the terms of reference and commissioning strategy are established.

This will change, however, as operators look for greater insight into and control over the production process, faster and better decision making, and more effective use of the often limited resources they place offshore.

The result will be the three Ps – greater Predictability over topside, subsea, and downhole offshore operations; more efficient People-based operations; and increased reservoir Performance with processes and assets designed and managed at the outset to play crucial roles in increasing efficiencies and reducing costs.

This will be achieved through a central nervous system that integrates process control and asset management and spans all facets of offshore operations from downhole subsea oil and gas reservoirs through to wireless-based smart fields and platforms.

Earlier this year, Roxar became part of Emerson Process Management to create the first integrated automation solutions company.

A central nervous system

By “central nervous system” (CNS), we mean a fully integrated digital architecture for field operations - diagnostics, predictive intelligence, and evolving technologies such as wireless, that better anticipate and react to problems before they impact topside, subsea, or downhole operations.

With the right predictive technologies to generate greater insight into what really is happening with the production processes, operators can anticipate and react to problems to improve reliability and profitability, to have greater operational control, and to drive efficiencies and better working practices.

One important element of the central nervous system is wireless.

Wireless technologies increase efficiencies and reduce costs for offshore operators. Smart wireless applications, for example, allow operators to add monitoring points throughout offshore facilities at a fraction of the cost of wired instrumentation. Such applications also reduce weight and footprint on platforms, and increase visibility of the operators’ assets and overall operations.

The costs saving of wireless technology is compelling. A recent study by Emerson of an actual offshore platform with about 4,000 I/O found that installing wireless along with other technologies in the process control system can save up to 7%, or more than $1 million.

A further elimination of some 800 wired points also means a weight saving of up to 35 metric tons (38.5 tons) and a reduction of required deck space of up to 129 cu m (168.7 cu yd) in cabling, cable trays, junction boxes, and cabinets.

Grane and Gullfaks platforms

Emerson Process Management has developed a smart wireless network to remotely monitor wellheads and heat exchangers, and generate vital production-based information on the Grane platform operated by StatoilHydro.

The field produces crude oil that is transported from the Grane platform to the Sture terminal near Bergen. Twenty-two wireless pressure transmitters are mounted on the wellhead to measure annular pressure, and 12 similar devices monitor inlet pressure and pressure drop over the heat exchanger. Each transmitter relays data via the network gateway to operator consoles in the control room. Personnel no longer must take manual readings in areas with high pressures and temperatures.

Wireless also monitors production processes on StatoilHydro’s Gullfaks field in the northern part of the Norwegian North Sea - an offshore field which has been developed with three large concrete production platforms.

Here, Emerson Process Management’s smart wireless network automates flow monitoring to increase production. Wireless devices transmit real-time temperature data that indirectly monitors flow, allowing a quick reaction to any loss of well pressure and for maximum well throughput.

Previously, StatoilHydro occasionally lost flow from producing wells at Gullfaks A, B, and C platforms because of wellhead pressure loss. Early detection of lost flow was considered vital to enable flow the well through the test separator to re-establish flow by reducing pressure.

Loss of flow was difficult to detect because there were no flow meters installed within the well pipes – something StatoilHydro wished to avoid as this would require a complete production shutdown.

In the past StatoilHydro detected flow loss by sending an operator to the wellhead to manually measure the difference between pipe temperature and ambient temperature. Automated monitoring would provide real-time data to reduce the number and frequency of personnel in hazardous areas.

StatoilHydro implemented Emerson’s wireless temperature transmitters on the platforms to indirectly indicate flow on lines at each of the 40 wells, while at the same time avoiding long cable trays and wiring.

In contrast to once-a-shift manual recordings, these wireless devices transmit readings every 30 seconds to the Smart Wireless Gateway. The gateway is hardwired into the existing control system to provide operators with real-time information to react quickly to any change in flow.

To date, StatoilHydro has implemented additional Smart Wireless devices on platforms A, B, and C, bringing the total to 90 wireless transmitters covering all production flowlines at Gullfaks.

Going downhole

Wireless is just one element of an integrated central nervous system for the offshore oil and gas field.

For process control and asset management to succeed efficiently, it must extend downhole into the reservoir as well as bridge the gap between subsea and topside wells. According to a 2004 report by StatoilHydro and the Norwegian Petroleum Directorate, subsea wells have a 15 to 20% lower hydrocarbon recovery rate than their topside counterparts. Much of this is due to lack of information from the seabed.

Intelligent subsea wells require continuous real-time reservoir surveillance, often through downhole controls, to evaluate production variations and to track wellbore performance. Measurements such as flow rate, fluid fraction, pressure, temperature, and chemical properties all can be made.

Multiphase meters downhole

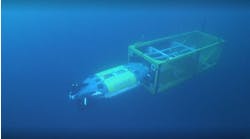

Multiphase metering is common for many field developments, helping wells produce at the maximum rate, while measuring trends in water and gas production.

Multiphase metering is an effective way to inspect subsea production capabilities in real time and to contributing to well intelligence and the fields’ central nervous system – primarily by going further downhole.

Moving multiphase metering technology downhole enables operators to monitor and control flow behavior more closely in wells with multiple producing zones. This results in higher daily output without risk to production from, for example, excessive sand or water. The combined effect is a better reservoir understanding, and, ultimately, increased recovery.

Downhole sensors

Use of extended-reach wells with multiple production targets, or multilaterals with several branches, also has given rise to the need to pinpoint not only production data from each wellhead, but also from each producing zone along each well path.

Downhole sensors are the only means to continuously monitor the production performance parameters of each individually perforated zone in a multilayer well.

Placed between each production zone and used to monitor temperature, pressure, and water cut, plus gas fraction, sand rate, and flow velocity, the sensors continuously monitor production performance parameters of each individually perforated zone of a multilayer well. An intelligent downhole network increases reservoir knowledge and reduces uncertainty.

When combined with the multiphase flow measurement, a problem can be detected by the multiphase meter and then pinpointed by downhole sensors. For example, if unwanted water or gas enters the wellbore, the multiphase meter detects the change in multiphase composition at the subsea wellhead.

The operator then can locate the problem by examining the real-time information from the downhole pressure and temperature gauges. Decisions such as choke setting and artificial lifts, for example, also can be made with the maximum amount of information.

Through its combination of instrumentation and predictive models from its software, Roxar can help continuously monitor production, observe, and control fields from remote locations, process large volumes of reservoir data quickly, and use up-to-date information to make operational decisions.

Miskar field – Downhole gauge in action

Roxar’s downhole gauges are used in the Miskar field in the Gulf of Gabes off the coast of Tunisia. In operation since 2006, the field supplies approximately 50% of domestic gas demand in Tunisia and, since 2006, has produced 14.4 MMboe.

The gauge has quartz pressure and temperature sensors, and silicon on insulator (SOI) electronics by Honeywell permanently installed in the well and is able to operate at temperatures of up to 225° C (437° F).

The gauge continuously transmits digitized pressure and temperature data to the surface to help BG Tunisia determine the best production rates for the reservoir to help allocate production to specific wells. BG Tunisia can access the information from any office.

About the authors

David Newman is director, Global Oil and Gas Sales and Marketing, Plantweb Solutions Group at Emerson Process Management. Vincent Vieugue is vice president, Sales and Marketing at Roxar Flow Measurement.