A European consortium is working on a deep sea observatory capable of performing remote geophysical, geochemical, and oceanographic observations at abyssal depths down to 6,000 meters. A prototype currently under construction will undertake the first extended deepsea mission for the consortium in the abyssal plain of the southern Tyrrenhian Sea next year.

In the long term, Geostar (Geophysical and Oceanographic Station for Abyssal Research) represents a promising technological solution for offshore engineering applications such as site characterization for subsea system structures, in addition to environmental tasks such as detection of marine pollution and earthquakes.

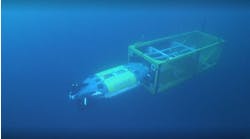

Prime components of the Geostar abyssal research station.

As the oil and gas industry moves towards exploration and exploitation of fields in ever deeper waters, it has to face the problem of executing geophysical, geotechnical, and environmental characterizations of the sites where future installations are foreseen. As a result, demand increases for innovative systems capable of operating autonomously, with minimal disturbance to the surrounding environments and with minimum supporting infrastructures. In many respects, these requirements are beyond the capabilities of presently available instruments and methods such as benthic landers or other packages deployed by manned semisubmersibles or even deepsea ROVs.

Long-term investigation

Recognizing these challenges, nine European institutions launched the Geostar project in 1995, aimed at developing a new generation of abyssal benthic laboratories for long-term multi-disciplinary investigations. Geostar has two main components:

- The bottom station, which is the instrumented observatory managing the operation of the payload, including communication systems and sensors

- The mobile docker, an ROV dedicated to deployment and recovery of the bottom station in a controlled and precise manner. It can carry heavy loads (up to 5 tons) at abyssal depths, deploy them with precision to within a range of 5% of water depth, and retrieve them at the mission's conclusion.

Perhaps the most outstanding feature of the whole concept is the possibility for Geostar to lower actively at the seabed and then retrieve with precision and care a package of sensors for collecting multi-disciplinary data. This package is heavy and cannot be dropped from the surface. The solution adopted overcomes limitations typically found with other systems, such as the free-falling deployment (rough and imprecise), short autonomy, and limited payload.

Station systems

The bottom station, designed and developed by Tecnomare, comprises five sub-systems - a frame, scientific payload, electronic control system, power storage system and communication system. Given the harsh environment and critical operating conditions in the Tyrrenhian Sea, a protective and stiff frame is required, capable of housing all the equipment and protecting it from any possible impact. The solution adopted is a structural frame with four cylindrical columns in a square pattern, connected by two orders of horizontal thrusts supporting the pressure vessels and the instrumented packages.

Another feature is the docking cone, the function of which is to insure a firm connection between the bottom station and mobile docker and to guide the latter during re-entry phases. This cone is composed of four beams and the support for the male part of the mechanical connection between the docker and bottom station, which is shaped as a pyramid that surmounts the lower part of the frame. The pressure vessels and frame have been constructed in aluminum - a second set of pressure vessels for 6,000 meters design depth is presently being manufactured from titanium.

For the prototype, instruments included are capable of measuring seismic, magnetic, water current, and water quality data. These will include a broad band three-axis seismometer, two magnetometers, a 300-kHz acoustic doppler current profiler, a CTD, a transmissometer and an electrochemical package. To minimize the impact of noise on measurements, the seismometer and magnetometers in particular need to be de-coupled from the source of that noise. That means isolating the vibrations caused by the environment that penetrate the main frame. The solution is to mount the instrument on a separate structure capable of shielding the sensor, protecting it from impacts, and allowing a firm coupling with the soil.

The magnetometers need to be located at least 2 meters away from other electric devices or power sources. For this reason, they are mounted at the end of rotating booms that are in a vertical configuration during the lowering phase before reaching their final horizontal configuration, thanks to the actions of gravity, buoyancy, and water drag. These operations are realized through use of mechanical actuators developed from standard acoustic releases.

Location of next year's extended deep sea mission off Ustica Island, north of Sicily.

Seabed operations

Once on the seabed, Geostar is managed by a dedicated data acquisition and control system (DACS), featuring:

- Minimum power consumption, due to the limited energy supplied by the battery pack

- Large number of communication channels, due to the instrumentation packages and peripheral devices that can be accommodated on the bottom station

- High data storage capacity, owing to the large amount of data produced by the instruments, in particular the seismometer.

The DACS comprises two intelligent units with high communication capability and two hard disk intelligent units with high data storage capability (up to 1 Gbyte). Two of these are employed in the bottom station, insuring 3,000 hour data autonomy.

Power regulation is based on DC/DC converters, while two dedicated electronic cards permit the mission management software to switch on or off each instrumented package according to the pre-programmed strategy or incidents such as failures or energy loss. Also, a status monitoring board is mounted inside the pressure vessels housing the bottom station electronics and battery pack.

Another set of sensors is devoted to monitoring the station's status and integrity during critical phases such as deployment, autonomous operation and recovery. These include a high precision echo sounder, a tilt meter, temperature, and water leakage sensors inside the pressure vessels, battery voltage, and current sensors. An energy requirement of 25 kWh max has been calculated for a three-month mission, which translates at 1,000 amp-hour at 24 volts. A primary lithium battery was used for the first mission.

Typically, autonomous seabed systems are limited by their inability to communicate with the users during the mission. As a solution, a dedicated communication system has been developed, capable of giving the user a permanent - though perhaps not continuous - update on events at the sea bottom. This system is based on expendable data buoys, or "messengers," that receive scientific and system status data periodically from the bottom station electronics. Once released to the surface, they send position and memory content via satellite to the mission control center.

During deployment, the bottom station is connected via the mobile docker's telemetry system to the surface unit, allowing the operator to carry out real time checks of the bottom station's status, operate releases and start the mission. Expansions for connection to real time communication systems such as underwater cable or a moored buoy in the immediate vicinity are also provided on the bottom station.

Mobile docker

The mobile docker can deploy and subsequently recover payloads up to 5 tons to and from a vessel. It is basically a simplified remotely operated vehicle. Maneuverability in the horizontal plane (x,y) is insured by two thrusters operated from the ship-borne operation console, while the ship winch regulates the ascent/descent (z).

Through visual and instrumental systems (DGPS, USBL), the docker operator can locate the pre-determined installation. For the prototype, an operating range of 5-10% of the water depth has been calculated and verified experimentally. Power transmission and data exchange are effected via an umbilical. A fiber optic telemetry system permits an extensive data exchange due to the high bandwidth.

The need for an easy and fail-safe connection system between the docker and bottom station has been solved through an interface comprising the docking cone and flexible pin (male part) on the bottom station side and the re-entry funnel with latch device (female part) mounted on the docker. For recovery, the docker must be positioned above the station - sliding between the docking cone and re-entry funnel guides the pin on top of the bottom station to the central latch device.

On top of the docker is a pyramid-shaped transportation frame made of high strength stainless steel which connects the latch device to the winch's mechanical cable. Aluminum profiles were manufactured for the frame and bumper system - their function is to protect and support the docker payload of cameras, compass, lighting, power, and electronic boxes..

An umbilical provides the power supply to the docker and a fiber optic line transfers several sets of data. An I/O rate of 19.2 kBaud guarantees transfer of all data required including optional sonar data. Telemetry can be used for an umbilical length up to 5,000 meters, extendable to 8,000 meters or beyond.

Control of thrusters, powered by brushless DC motors, is effected via a control circuit placed at the ship's docker operator console. The docker system and its behavior in operation have been tested firstly with numerical flow simulation and then with laboratory tests in the Technische Universitat Berlin/ZE VWS water tunnel. Geostar has also been tested extensively in Ifremer's deepwater tank in Brest, France to verify in controlled real conditions (20 meters water depth) all the system's components and operative procedures.

First Adriatic mission

The conclusion of the first development phase involved tests in the Adriatic Sea during a three-week mission during 1998, at a site 50 km offshore Ravenna in 42 meters water depth. Marine operations were managed by Istituto per la Geologia Marina from the research vessel Urania. During this mission, the bottom station acquired data continuously and stored them in the station memory. An expendable messenger was released after 10 days. The station's status was checked via acoustic link in a survey using a light boat of convenience. At the mission's end, the Urania returned to the site for recovery operations.

Preliminary analysis of the 400 Mbyte of data downloaded from the disks indicated that the bottom station managed the programmed mission successfully. A total of 440 hours of scientific data were acquired and stored (97-98% efficiency). All scientific and communications packages interfaced to the bottom station worked correctly. Analysis of the status sensors indicates that all the internal parameters were in the correct ranges and the power supply was in line with the design calculations.

Geostar is now undertaking an enhancement phase. Results of the first mission highlighted the need for modifications for the first deep sea mission, which will be performed in May-October 2000 in the Tyrennhian basin, at a point 25-30 km north northeast of Ustica Island in 3,400 meters water depth. This an area of oceanic crust of Pliocene age.

As the precursor of a new generation of ultra-deepwater observatories, Geostar could be exploited for various significant offshore-related applications, including:

- Hosting instrumented packages devoted to acquisition of measurements related to cathodic protection design and geotechnical parameters

- Long-term collection of seismological data. A significant example in this regard is Petrobras' Procap-2000 program, aimed at characterizing the Brazilian continental shelf in the Campos Basin (2,000 meters water depth) and including an activity devoted to seismic monitoring, for which the use of instrumented benthic stations is foreseen

- A support platform/testing facility for deep sea ROV performance evaluation, long-term test of materials, and instrumented packages or components such as valves and connectors. Major savings could be achieved by addressing several technological programs at the same seabed site, by having common infrastructure (support station, data gathering system and power source) and also using the same ship-borne logistic facilities.

Partners in this European Union-funded project include Istituto Nazionale di Geofisica, Ifremer, Laboratoire d'Oceanographique et de Biogeochimie, Technische Universitat Berlin, Thetis, Tecnomare, Orca Instrumentation, University of Newcastle upon Tyne, and CNR Istituto di Geologia Marina.