Working toward a 60-mile radius

Frank Frazer

Contributing Editor

- Figure 1 - Layout of Zafiro project. [5,545 bytes]

- Figure 2 - Kongsberg's guideline-less HOST template. [33,092 bytes]

- Figure 3 - Host control configuration. [26,818 bytes]

- Figure 4 - Global deep-water spending to 2002. [6,643 bytes]

Among innovations adopted to achieve savings in underwater engineering is the modular-based Hinge Over Subsea Template (HOST) system developed by Norway's Kongsberg Offshore. So far, more than 50 of the systems have been installed in areas from the North Sea to West Africa, and ongoing development is expected to make enhanced versions of the technology an increasingly attractive option for future projects in the Gulf of Mexico.

Kongsberg has designed HOST to provide maximum flexibility, especially for situations in which initial project configurations have to be drawn up with limited reservoir data in the absence of a comprehensive field appraisal program.

The benefits of using technology such as HOST in such circumstances were highlighted by Kongsberg's Subsea Marketing Manager Carl Steenstrup at the fifth Atlantic Margin conference in Aberdeen, organized by Robert Gordon University and Smith Rea Energy Analysts.

Design flexibility

Steenstrup said the use of standardized interchangeable modules provided the system with design flexibility required to meet reconfiguration challenges as more reservoir knowledge became available within the demands of a compressed project schedule.Steenstrup chose the development of Mobil's Zafiro deepwater project offshore Equatorial Guinea (Figure 1) to demonstrate how HOST technology could save time and money. The reserves lie in 400-1,600 ft of water with a floating production storage and offloading system (FPSO) installed in 600 ft of water acting as the main production facility.

The first phase of the project consisted of eight diverless satellite trees individually tied back to the FPSO by 6-in. flexible flowlines and direct hydraulic control umbilicals. The flowlines were grouped in interconnected pairs for round-trip pigging, with offset distances from the trees to the FPSO at 1-4 miles.

For the fast-track second phase of the project, processing capacity in the FPSO was doubled to 80,000 b/d. Three HOST template/manifold systems were ordered for installation at depths from 900 ft to 1,600 feet at distances ranging from one mile to five miles from the vessel. Each manifold was linked to the FPSO by twin production flowlines of either 6-in. or 8-in. diameter and an electro-hydraulic control umbilical. The systems were located to drain satellite structures called Zafiro West, Topacio, and Jade. The flexibility of the system allows trees to be located on or off the template. Off-template trees are connected to the manifold by 4-in. production and 2-in. gas lift flowline jumpers and electro-hydraulic control umbilicals.

HOST features

Among the main technical features of the HOST system is the drilling template, which is configured with up to six wing elements that hinge up to allow the component to be passed though a moonpool with dimensions of at least 18.6 ft by 20.3 ft. The wing elements are later hinged down to form the template and can serve as well slots, flowline tie-in porches, or other modular interface units.The production manifold is configured with two 6-in. production headers and one 4-in. gas lift header. There is a pigging loop module that can be removed to permit the daisy-chaining of HOST systems or the installation of a subsea multiphase pumping module. All flowline connections are made with a universal tie-in system using a single-trip flowline pull-in and connection tool. Flowlines can be rigid or flexible pipes with diameters up to 13-5/8-in.

Engineers planning the second phase of the Zafiro project took full advantage of the flexibility offered by the modular subsea building blocks provided by components with standardized interfaces. This enabled installations to be customized to meet specific functional requirements, with each of the three templates configured differently. The hardware requirements were more complex than the eight subsea trees with direct hydraulic controls ordered for the first phase, which came onstream in August 1996.

As well as the mix of on- and off-template trees, the second phase had a multiplexed electro-hydraulic control system. But Kongsberg was able to meet a similar tight schedule by delivering the orders for the three templates and six of the nine trees, with associated control systems, within a year of the orders being placed.

Standardization

According to Steenstrup, the fast-track achievement was helped by a positive working relationship between operator and supplier. The number of subcontractors involved in the project was kept to a minimum but with the workscope of each maximized for greater effectiveness. Engineering innovation throughout the project was focused on shortening lead times and establishing clear and simple interfaces.Design features of the HOST system further help to achieve fast-track completion targets. Dimensions and weights of components are kept within truckable limits to help the logistics of delivering the equipment to remote locations. They can be shipped in any standard cargo vessel to ports equipped with cranes of sufficient capacity to handle normal offshore supply vessel operations.

In addition, manufacturing operations do not require the shore-based fabrication yards that are typically used for the assembly of large unitized templates. HOST modular components can be manufactured at any convenient facility with adequate welding and machining capability, independent of location. Work can also be carried out on offshore vessels with sufficient crane capacity to handle delivered modular components.

Steenstrup said that the system had the added advantage that installation could be carried out directly from a drilling vessel with an adequate moonpool and a deck crane lifting capacity of at least 35 tons.

"This obviates any need to mobilize heavy lift crane barges or other construction vessels that are typically not readily available at remote project locations. Once onboard the installation vessel, modular equipment offers reduced installation times since smaller packages typically have a more tolerant weather window for deployment," he added.

The latest work on Zafiro was competed using two vessels - the ship-shaped Robert F Bauer support vessel and the semisubmersible rig Aleutian Key.

Steenstrup concluded: "The Zafiro Phase 2 project has proved the value of using a modular subsea production system to develop hydrocarbon resources in a remote operating region of the world on a fast-track basis. However, modular system benefits are not limited to remote areas or fast-track schedules - they are universally applicable."

Guidelineless use

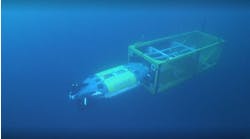

The Zafiro components were installed with the help of guidelines, the conventional method of placing installations on the seabed. But since the early 1990s, Kongsberg has been working with major oil companies to adapt components in its HOST for guidelineless use to meet expected market demand for technology that will reduce capital and operating costs (Figure 2).The new components will maintain the mix-and-match features of the present technology to offer the same flexibility to make changes in field layout after orders for systems have been placed. "We expect this to be very much the normal case for field developments in the future, since rig capacity is limited and it is very expensive to drill appraisal wells," Steenstrup said.

The guidelineless system can accommodate either conventional or horizontal christmas trees. Features of the system were demonstrated and verified in a series of shallow-water tests at the Nutec facility in Bergen in the summer of 1997, including the christmas tree guide funnel and re-entry system, ROV installation and retrieval of the chemical injection valve, and installation of the composite steel tube umbilical by ROV.

The system offers a choice of designs for foundation units to cope with hard, medium, or soft soil conditions. With soft soils most common in likely areas of deepwater application, the unit's central pile is combined with a skirted anchor to take horizontal loading. After wells are drilled and anchored, the conductors also act as foundation piles to relieve pressure on the central pile.

The manifold module for each installation is custom-manufactured to suit the requirements of individual customers. The unit commingles the flow from connected wells to one or two manifold headers. Manifolds are laid out for a variety of applications to cope with both high and low production rates, pressures of 5,000 psi and 10,000 psi and high temperatures. The unit also contains electric trunking and hydraulic piping for connecting the umbilicals to the manifold and providing further connections for trees installed on or off the manifold.

The basic control system for the guidelineless HOST concept uses electro-hydraulic multiplexed technology serviced by an integrated umbilical through a control module developed for guideline systems (Figure 3). The technology has been field-proven in 3,000 ft of water through applications for Petrobras at the Hercules and Marlin fields in Brazil and Agip's Aquita project in the Adriatic. The latest version of the control system has been tested and verified for use at depths to 7,500 ft.

Some of the technical challenges facing subsea engineers planning installations in deepwaters off West Africa were reviewed in another paper at the conference by Philippe Rogier, foreign affairs director of Institut Francais du Petrole.

60-mile radius

Although the area has been one of the recent exploration hot spots with major finds such as Dalia, Girassol, and Rosa made by Elf off Angola, Rogier said that there were probably fewer than 100 large fields with reserves of more than 100 million bbl. But he estimated that there were several hundred smaller fields which cumulatively represented a significant part of the potential global market for offshore technology.Rogier said that many of those fields would not justify stand-alone facilities and would have to be developed as satellites to larger discoveries. "The energy of the reservoir and the distance to the existing facility become then essential parameters for the development design," he added.

He said that where reservoir energy was high and the distance less than 10 miles, a direct tie-back would be possible - if a spare slot was available on the host field subsea wellhead template. "The main problem in such a case comes from pigging the lines. Deep water means low temperatures at the wellhead and in the flowlines, which has the consequence of increasing the possibility of hydrate formation as well as wax deposit," he explained.

The problems could be resolved by chemical injection through service umbilicals and pigging the lines. But those two operations would be very difficult if the receiving template had not been designed for those functions, Rogier said.

In the case of reservoirs with weak energy levels and distances greater than 10 miles from host facilities, other solutions such as downhole electric pumps or surface boosting of multiphase flow would be required.

This would require a larger number of connections not only with the host template but between the subsea installation and the FPSO. Rogier suggested that consideration may have to be given to using small unmanned satellite vessels to provide control, chemical injection, and power supplies operated remotely by telemetry links with the host facility.

By using this type of satellite floater, Rogier thought it should be possible to develop discoveries in an area up to a 60-mile radius around a large field. He said the use of the concept could also substantially improve the economic efficiency of the host development and extend the duration of its life.

On the scale of likely deepwater developments off West Africa, Rogier said potential recoverable reserves could range from 20 billion to 40 billion barrels, of which 10 to 20% had so far been discovered. He estimated that multi national companies would need to invest more than $4 billion to make the most of the opportunities over the next five years. This would mean that the West Africa deepwater market, representing 19% of world total spending on deepwater development, would become the second largest market after the Gulf of Mexico (Figure 4).

Copyright 1998 Oil & Gas Journal. All Rights Reserved.