Proper planning allows Saudi Aramco to upgrade facilities in busy offshore area

Executing a major offshore construction project is a challenging task by itself. There are tremendous risks associated with the marine operations and installation work that must be mitigated every step of the way. The risks are much higher when the major offshore construction is taking place in an existing operational field.

Saudi Aramco’s Marjan & Zuluf Increments are considered among the most ambitious programs worldwide. The programs will boost the country’s position as a leading figure in providing reliable energy to the world. The fact that both programs are to be executed in these busy and congested mature offshore oil fields, while maintaining normal hydrocarbon production, is considered one of the most complex challenges ever taken by the company in the offshore projects execution sector.

Since the initiation stage of both programs, the offshore execution part has been identified as the biggest challenge that the programs have to manage. Multiple construction contractors will be working simultaneously in busy and congested oil fields—over and around live and operating subsea and above water facilities—mandating extraordinary mitigation measures to be adopted and implemented.

The project management team worked in close coordination with the operation and marine departments to properly plan and implement many mitigation measures addressing the huge challenge. The mitigation measures span over almost all project execution phases. Some of these measures have been implemented as part of the awarded contracts, while others are being implemented in the engineering and detail design phase; and the remaining will be implemented in the construction phase.

Through proper planning and front-end marine traffic and risk studies, the team identified and implemented multiple measures to mitigate the risks. These measures included utilizing only class 2 and 3 dynamic positioning systems; dedicated navigation channels and anchorage areas; implementation of renewable energy solutions; elimination of crossings; and other administrative measures associated with the fields’ management and marine vessel control.

Project execution challenges

Offshore and subsea construction work poses some of the greatest technical, logistical and safety risks in the construction world. The installation of the heavy offshore structures involves extreme heavy lifting operations (up to 5,000 tons); the installation of extra heavy structures that cannot be lifted (in the range of 10,000 to 20,000 tons); the laying of hundreds of kilometers of subsea pipelines and cables; and the execution of specialized diving operations.

The risks associated with each activity can be tremendous, and often pose real danger to properties and personnel working in these offshore oil and gas fields. Such risks multiply drastically when working within existing operational fields that are already producing and busy with ongoing drilling and maintenance activities.

The Marjan & Zuluf offshore oil fields are the second and third largest offshore fields in the Arabian Gulf. Both fields currently produce oil from around 100 offshore platforms, six offshore gas oil separation plants, and hundreds of kilometers of subsea pipelines and cables. Each year, both fields receive additional facilities to maintain field potential and replace aged facilities.

In addition to the ongoing maintain potential programs, the fields are due for substantial increment projects, which are part of Saudi Aramco’s continuous plan to strengthen its position as one of the world’s leading producers of oil and gas. Through the Marjan Increment Program that has already commenced, and the upcoming Zuluf Increment Program, the two offshore fields will receive tens of additional offshore oil, gas, and water injection platforms, and additional hundreds of kilometers of subsea pipelines and cables.

Executing these increments in busy, producing offshore fields pose great challenges and risks. These can be narrowed into three main categories:

Marine traffic and logistics. Both of the Marjan & Zuluf fields are operating fields. The fields currently run a busy production operation with a heavy presence of boats to support operation, maintenance and security personnel roaming around the fields. In addition, the ongoing maintain potential projects also add a substantial number of marine vessels to support drilling and workover rigs and the construction of the maintain potential facilities. It is estimated that both fields have an average daily presence of 100 boats/barges a day, ranging between heavy lift construction barges, jack-up barges, cargo barges, field service boats, work/maintenance boats, crew transfer boats and supply/fuel/water boats. Organizing such heavy marine vessels presence within the limited boundaries of the fields, and ensuring the safety of the personnel and existing subsea and topside assets, is already a huge undertaking by the Saudi Aramco marine department.

Executing significant increment programs and adding tens of offshore facilities, drilling tens of wells and installation of hundreds of kilometers of subsea pipelines and cables will at least double the number of marine vessels and barges present in both fields. Thorough risk analyses and mitigation plans will need to be proactively put together to properly manage the marine traffic and logistics, ensure safe ongoing operation and execution of the drilling and construction activities that will accompany the increment programs.

Interface with subsea assets. Another challenge that is associated with the busy offshore fields is the presence of a complex mesh of subsea pipelines and cables connecting the existing/producing facilities. To put things in perspective, Marjan field for example is an area of 20 km wide and 30 km long. Having hundreds of kilometers of subsea pipelines and subsea cables connected in a small geographical area is a remarkable achievement already. Now, adding hundreds of kilometers of additional subsea pipelines and cables within the same area is a logistic and safety challenge. The new lines will need to cross over the existing/producing subsea pipelines and live subsea cables and any miscommunication or faulty installation operation can lead to subsea pipeline damage or interruption of ongoing operations.

Offshore construction cost and logistics. Executing normal offshore construction work in a completely green field area is a very expensive business. The cost of the offshore specialized construction resources is extremely higher than similar construction activities in onshore. Many of the required resources are specialized barges are rare around the world. For example, there are only a small number of heavy lift barges that can lift an excess of 5,000 tons, and only three or four cable lay barges that can lay the required length of cable in one run between the coast line and Marjan field. The cost and logistic challenges grew even bigger when trying to execute these offshore construction projects in busy fields with the required safety and precaution measures.

The project management team within Saudi Aramco realized the above challenges at the early stages of planning for the increment programs. Marjan & Zuluf increment projects department worked with the integrated project team members from all relevant Saudi Aramco organizations to properly plan and mitigate the above identified risk categories. The teams conducted thorough analysis and came up with early mitigation measures, and utilized the latest technologies to ensure safe execution of the offshore construction activities with no interruption to the ongoing production and drilling operations.

Studies and mitigation measures

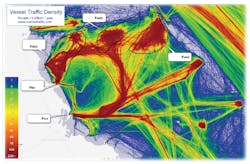

Realizing the challenges ahead, the team kicked-off a study to model and analyze the marine traffic, taking in consideration the ongoing operation and the forecasted increase in activities during the execution of the increment programs. The study utilized the latest computer modeling to generate heat maps and risk areas for both offshore oil fields.

The heat maps were then utilized to identify the major contributors to such increase in traffic and risk factors. The team then conducted series of brainstorming sessions to identify the measures that can be implemented to reduce the risks. When identifying these measures, the latest technologies in marine vessels management and facilities design played a major role in the reduction of risks.

Some of the major implemented measures were as follows:

Utilization of renewable energy. The increment projects department analyzed the power requirements of the programs’ relatively low-power consuming facilities (such as the water injection platforms) and adapted the utilization of solar panels in lieu of running new subsea cables. The decision led to eliminating tens of kilometers of subsea cables required to power the offshore platforms. As such, this design directly addressed and mitigated all three risk categories by significantly lowering the number of subsea cables (reducing the subsea interfaces and crossings), reduced the number of required cable lay vessels (contributing to lowering the marine traffic) and provided more cost-effective design. As an added bonus, the design is more environmentally-friendly with the utilization of renewable solar energy instead of the traditional subsea cable approach.

Subsea pipeline design. The traditional design of offshore production platforms is using a direct subsea pipeline from each production platform to a collecting platform known as a tie-in platform. The tie-in platform collects the production from multiple (8-10) production platforms and send the gathered production to the gas oil separation plants for processing. This typical arrangement requires hundreds of kilometers of pipelines to transfer the produced hydrocarbon to the processing facilities. Moreover, each pipeline requires continuous maintenance and scraping operations to preserve and prevent corrosion. The Marjan & Zuluf increment projects department capitalized on this offshore best practice approach to design the subsea pipelines configuration with a multilateral approach requiring only one pipeline for every group of platforms. The pipeline starts from a leading platform while the others connect join-ins using a lateral approach.

The project has also adapted the utilization of flexible lines for the lateral connection. The flexible lines technology provides an excellent nonmetallic alternative to the traditional rigid carbon steel pipelines. Although flexible lines may have limitations in length and size for longer runs, they work perfectly in lateral connection and provide scraping free corrosion resistance product for oil production.

Utilizing this laterals approach significantly eliminated tens of kilometers of subsea pipelines and crossings between the new pipelines and the existing subsea pipelines and cables. The number of marine vessels required to install the pipelines was also reduced, in addition to the reduction in marine traffic during normal field operations (with the elimination of scraping requirements for the flexible pipelines).

Contracting strategies. The project team has also taken several steps to properly plan the construction activities and reduce or eliminate risks during the construction phases. From a planning perspective, the contracting strategies of the projects has taken into consideration the marine traffic and crossing risks, and adapted a geographical-area zoning strategy. This contracting strategy is designed to reduce overlapping and interfacing between construction contractors, and to allow each construction contractor full access to his construction site independently, with a dedicated marine channel without the need to cross the busy field center.

Construction simplification. The selection of the platforms locations and the routing of the subsea pipelines and subsea cables has been planned/selected to provide the lowest possible number of crossings. Wherever possible, the team has also utilized the design of double subsea crossings, where one crossing structure is deployed on the seabed to protect the existing adjacent subsea pipelines and cables before crossing them with new ones. As a result, the number of overall crossings has been significantly reduced, providing cost and risk avoidance during offshore construction.

Moreover, the design of all heavy, large and complex facilities has been planned with the purpose of simplifying offshore construction. The team designed the extra-heavy platforms (weighing 5,000 tons or more) to be installed using float-over techniques. The float-over installation (as can be seen in the picture) eliminates the need for the rare, expensive and massive extra-heavy lift barges. These barges usually come with a fleet supporting vessels, tug boats and anchor handling operations. The float-over installation method is a much simpler installation technique that utilizes fewer marine resources.

On the pipelay, cable lay and diving fronts, Marjan & Zuluf projects adapted the utilization of DP vessels in all construction operations. The DP vessels utilization eliminates the need to deploy anchors to control the movement of the barges and the installation work. Instead, DP systems utilizes satellite GPS technology to control the barge’s thrusters, and adjust the position and movement of the barge automatically. This in turn eliminated massive anchoring work on the already congested seabeds of both fields and significantly reduced the risk of dropping anchors on live subsea pipelines and cables, and causing damage to personnel, assets and the environment. The marine traffic concern has also been mitigated with the elimination of the anchor handling tugs and continuous deployment, recovery and movement of anchors from one location to another.

Marine management and mitigations. Realizing the challenges associated with the execution of these two major increments and as part of the integrated project team, the Saudi Aramco marine department has also proactively implemented several operational control measures to ease the movement and reduce the traffic in the busy offshore fields. The marine department increased the number of anchorage areas in both fields from two to four, providing safe designated areas for the vessels/barges to shelter during bad weather periods, and avoid the risk of damage to existing (or new) subsea and topside facilities.

Moreover, the marine department adapted and approved additional designated navigation channels for vessels to move between fields and back-and-forth from shore. These channels work like super highways and control the marine traffic through known, safe, and continuously monitored lanes, to avoid scattered traffic all over the fields in the Arabian Gulf.

Other implemented measures also included:

Increased vessel traffic. The existing VTS systems supporting the field are undergoing review, and will possibly be upgraded to IALA Level 2 Traffic Organization Service. This will provide more advanced operational management techniques and decision support tools that will play a major role in managing and mitigating navigation risks. These techniques and tools can include:

- One-way vessel transit in defined areas

- No passing/meeting of vessels in defined areas

- No overtaking in defined areas

- Use of escort tugs for large barges/vessel move

- Maximum speed limits

- Maximum draught requirement

- Daylight operations only

- Prohibited areas to be avoided

- Safety and exclusion zones

- Maximum tow lengths

- Prohibited anchorages

- Restricted operations in certain weather conditions

- Time, distance and geographical separation of vessels

- Mandate routes to be followed

- Traffic separation schemes/reporting schemes.

Enhanced master training. Saudi Aramco realized the need to focus on the vessels’ masters and make them appreciate the changes taking place in the offshore fields. Therefore, an enhanced training scheme is being put in place for the masters and mates of vessels engaged in the increment programs. The training will allow these key vessels’ personnel to make better decisions, and improve situational awareness of increment and baseline vessel traffic activities. The training will be similar to the harbor pilots’ general scheme in aspects related to navigational features/obstructions and details of the navigation safety during the construction phases.

Enhanced vessel specifications. In addition to the mandate of utilizing on DP vessels as explained earlier in the paper, Saudi Aramco is also looking into mandating other specifications for the vessels that will be involved during the construction phase of the increments. Examples include Electronic Chart and Display Information System (ECDIS) to provide collision avoidance warnings. The ECDIS displays the ships position on the electronic charts in real time and takes feeds from the ships GPS, radar, log, compass and AIS systems. It can provide fused traffic image, bring all sensors together, and use collision algorithms to identify and warn the bridge team of impending collision situations that can be avoided.

Declaration of information. Declaration or promulgation of construction information is important to ensure that vessels transiting (or planning to transit) in the fields are familiar with the planned operations. The following forms of declarations are being adapted:

- Regular notices to vessels – created by a dedicated hydrographic survey unit and issued by the company’s marine department

- Marine information broadcasts

- Provision of projects’ specific mapping files and chart plotters.

Routing measures. The completed studies showed that there are cases of 300 vessels/day moving in the two fields during the peak periods of the construction work. This is a substantial increase from the average 90 vessels/day during regular operations. As a mitigation measure aimed towards reducing vessel density, mandatory routing measures are being introduced. By implementing special routing measures, the fields can be split into color-coded sectors; and then, vessels can be routed into, out of and around the field, as needed and mandated.

Path forward

During the construction of the increment programs facilities, the Saudi Aramco project management team, along with Marine and Operations Departments, are planning to deploy a state-of-the-art Marine Control Center (MCC) to continuously monitor, control and direct the marine traffic associated with ongoing operations and new drilling and construction activities.

Similar to flight control systems in busy airports, the MCC will be directly connected to the vessels tracking system that will be mandated on all marine vessels working on Saudi Aramco fields. The human-computer integrated staff will be planning and monitoring all marine traffic, and will have live-feed on the subsea construction/laying activities, heavy lift and float-over installations and diving operations.