David Paganie • Houston

MMS tags platforms high-consequence

The US government has collected mitigation plans from the operators of existing platforms categorized by MMS as “high-consequence” that do not meet the latest metocean criteria in the MMS-defined Central Region and adjacent transition regions. At print, 92 platforms in this area had been tagged as high-consequence. The regulatory agency had not set a deadline on when the operators of these platforms must complete the planned mitigation, but the clock is ticking, says BJ Kruse, chief of the Office of Structural and Technical Support, MMS. “The operators of these platforms need to show some mitigation to make the structures withstand the new metocean criteria as outlined in API Bulletin 2INT-EX,” he says. “We are evaluating each plan and determining whether or not there is an appropriate level of mitigation. And we anticipate getting back to each operator as soon as we can.”

Platform assessment

MMS has determined that existing platforms in the Central Region area, defined as from the State-Federal boundary seaward between 90.5° W and 85.5° W, are subject to the highest level of increased environmental loading (i.e. waves, winds, etc.), according to the updated metocean criteria in API Bulletin 2INT-MET. As a result, the platforms in this area are subject to an increase in air gap from 8 to 15 ft (2 to 5 m).

On Oct. 1, 2007, in a Notice to Lessees and Operators (NTL 2007-G27), operators were asked to conduct an assessment of the fixed platforms identified in Section 2.2 of API Bulletin 2INT-EX, by June 1, 2008.

Following the completion of detailed engineering, Versabuild can mobilize its current deck jacking system and leg extension sections in 10 to 12 weeks. Installation of the leg sleeves/additions can take from two to four weeks depending on the number of platform legs and ease of access under the cellar deck. Photo courtesy of Versabar.

According to the NTL, under Section 1.7 of API RP 2A-WSD, Section 1.7.2.a of API RP 2A-WSD, and Section 17.3 of API RP 2a-WSD, MMS determined that the following fixed platforms fall in the assessment category:

- Platforms that are subject to the Platform Verification Program and other platforms installed in water depths greater than 400 ft (122 m)

- Platforms that produce or handle sour gas (H2S concentrations greater than 500 ppm)

- Platforms located 10 mi (16 km) or less from the coastline that store more than 2,000 barrels of liquid hydrocarbons at atmospheric pressure or blanket gas

- Platforms located more than 10 mi from the coastline that store more than 5,000 barrels of liquid hydrocarbons at atmospheric pressure or with blanket gas

- Platforms that produce greater than 5,000 b/d of liquid hydrocarbons

- Platforms that have a liquid hydrocarbon throughput greater than 15,000 b/d

- Platforms that produce greater than 25 MMcf/d of natural gas

- Platforms that have a natural gas throughput greater than 75 MMcf/d of natural gas.

According to the NTL, operators of these platforms were asked to conduct an assessment of the structures by performing an Ultimate Strength Analysis in accordance with Section 3.3 of API Bulletin 2INT-EX, and carry out a cite-specific study of hurricane metocean conditions according to Section 9 of API Bulletin 2INT-MET.

For existing floating platforms, operators were asked to conduct an assessment using the three-step process outlined in Section 2.2 of API Bulletin 2INT-EX. The three steps are: 1) design level check, 2) survival check, 3) and a robustness check.

Mitigation plans

By June 1, 2008, operators of all 92 platforms identified as high-consequence in the Central Region were required to submit results of the platform assessments to MMS. Operators of the platforms that were deemed not in compliance with the updated metocean criteria were required to submit a mitigation plan to get the platform in compliance. MMS notes that it did not receive 92 mitigation plans.

MMS could not discuss the specifics of the mitigations plans, but they did provide some example mitigation methods to sustain increased environmental loading. Raising the platform deck is the best way of protecting against sustained increased environmental loading, but there are other ways of reducing the load that the platform is exposed to, Kruse explains.

Most of the damage to a platform is at the water level, he says. “Some of the conductors and the piping and associated processing equipment on the lower level deck could be removed to decrease some of the exposure to wave loads. Also, some of the lower level deck, the boating landing on the bottom level if unused, walkways, stairways, and any dormant conductors or risers running up the platform, could be candidates for removal as well. Removing excess inventories of hydrocarbon storage on the platform is another mitigation strategy.”

MMS does not anticipate any shut in of production or acceleration of decommissioning schedule as the mitigation plans are carried out.

Meanwhile, MMS has updated damage statistics from the 2005 hurricane season: 108 platforms were destroyed, 58 platform removal plans have been approved (at print), and 792 wells were damaged; 312 have been plugged and abandoned (at print) and the rest will be shut in within the next 1-2 years.

Hurricane season 2008

The National Oceanic and Atmospheric Administration (NOAA) predicts above normal hurricane activity in itsAtlantic Hurricane Season Outlook. The NOAA projects 12 to 16 names storms will form in the Atlantic basin, including six to nine hurricanes, of which two to five will be intense (category 3, 4, or 5 on the Saffir-Simpson Scale).

The seasonal average was 10.3 named storms, 6.0 hurricanes, and 2.4 intense hurricanes, during 1950-2007, according to the Energy Information Administration (EIA). The GoM region has averaged 3.4 named storms and 1.7 hurricanes (0.8 intense).

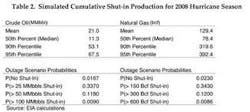

The EIA takes forecasting hurricane impact a step further, with the inclusion of an outage estimate. The administration estimates shut-in production during the 2008 hurricane season to be about 11.3 MMbbl of oil and 78 bcf of natural gas, based on results of its Monte Carlo hurricane outage simulation. The results suggest that there is less than 1% probability of experiencing seasonal outages similar to 2005 when hurricanes Katrina and Rita struck the Gulf Coast. But there is a 98% chance that production in the GoM will be impacted, the results indicate.

Mariner makes deepwater discovery

Mariner Energy has made a discovery on its Geauxpher prospect in Garden Banks block 462 in 2,700 ft (823 m) of water. The well was drilled to 23,156 ft (7,058 m) TD. Mariner estimates the field’s gross proved and probable reserves to be approximately 100 bcfe of natural gas. First production is expected by year-end.

Meanwhile, Mariner has expanded its deepwater prospect inventory, farming into the Heidelberg Miocene subsalt prospect with a 12.5% interest. Heidelberg is operated by Anadarko Petroleum Corp. on Green Canyon blocks 816, 859, 860, and 903. An exploration well is expected to spud on the acreage by year-end.

Daniel Boone development sanctioned

W&T Offshore has sanctioned the development of its Daniel Boone field in Green Canyon block 646. The development plan calls for a subsea tieback to theFront Runner spar. The discovery, drilled in 2004 to a total measured depth of 12,365 ft (3,769 m), encountered approximately 275 ft (84 m) of high quality oil and natural gas-bearing sands, according to W&T.

Meanwhile, Hess is evaluating development options for its Pony field following positive appraisal results, the company says. The Hess-operated Pony No. 2 sidetrack well in Green Canyon block 468 has encountered the same objective sands as Pony No. 1 and No. 2 wells, according to Hess. The well reached a measured depth of 33,362 ft (10,169 m) from a surface location 7,400 ft (2,256 m) northwest of the discovery well. The main pay sand was oil-filled throughout the interval drilled, Hess says. Recoverable resources are estimated to be approximately 200 MMboe.

Noble rig upgraded

TheNoble Amos Runneris drilling in the Gulf of Mexico following Signal International’s delivery of the upgraded semisubmersible drilling rig seven days early.

The shipyard work, done at Signal’s Pascagoula East facility, primarily was to enhance the rig’s ability to maintain station during severe weather.

The mooring was upgraded to a NC5 rating and the equipment was enlarged from a nine-point spread to a 12-point spread. To enhance stability, 520 tons (472 metric tons) of column water plane tanks were installed and 270 tons (245 metric tons) of windlass deck extensions were installed for added mooring winches. Column anchor bolsters were modified to accept larger-capacity anchors. Columns and diagonals were painted and a five year American Bureau of Shipping survey was completed.