Methodology offers realistic offshore campaign plan

Shawn Saadipour

Chevron U.S.A Inc.

The time and cost of offshore activities are often underestimated. Even if those activities are executed on time, they may experience unplanned cost overruns. Realistic planning can help significantly mitigate these issues, as many of them can be foreseeable if the right analysis is conducted.

The goal here is to describe an approach to incorporate POB limits (Persons on Board) into the planning process during an offshore campaign for a facility installation, hook-up and commissioning in the deepwater Gulf of Mexico.

The quality of offshore planning can be adversely affected by the following shortfalls:

Underestimating required man-hours. Good quality pre-commissioning check sheets provide the right estimate for required man-hours and crafts (mix and number) to accomplish the work. Productivity, on the other hand, is not easy to estimate. Productivity of previously executed projects can be a good benchmark. However, it is important to note that poor quality planning can result in chaos which would adversely impact the productivity, hence misleading and running the risk of failure.

System completion strategies not incorporated into the plan. Hook-up and commissioning of an offshore facility can be handled differently depending on strategies and considerations that system completion team adopts. These strategies shall be reflected in the schedule through logical relationship between activities. One example is commissioning sequence of some of the systems.

Exclusion zones/hazard area classification not considered. Due to safety considerations, there are equipment and systems that cannot be commissioned at the same time even if there are no workforce constraints. These considerations shall be incorporated into the schedule by allocation of artificial resources and conducting resource leveling for these resources.

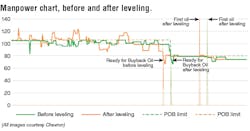

POB limit has not been properly taken into consideration. There are laws and regulations around POB and required lifesaving equipment on a vessel or offshore facility which are enforced by government agencies. The United States Coast Guard enforces pertinent regulations in the Gulf of Mexico which apply to offshore facilities with persons onboard during sailaway, installation, HUC and operation. POB limit on an offshore facility is typically elevated prior to introduction of hydrocarbons, but is reduced once hydrocarbon is introduced in the system. Managing different POB limits during HUC planning process is a challenge. Lack of POB consideration at various stages in the schedule usually results in underestimating the overall duration of HUC activities. By planning the campaign with consideration of POB limit, projects can properly plan for a right size accommodation and construction support vessels (floatel) which maximize efficiency and in turn reduces the cost.

Lack of advance resource planning. Availability of workforce at the right time when they are needed is one of the key factors for successful offshore projects. This becomes more significant when a workforce requires entry visa or is available for a specific period due to other commitment, typical example is vendors’ representatives.

The method that is presented in this article is only a remedy for last two items addressed above. However, it is important to mention that applying POB limit to the plan is the last step in development of a realistic offshore plan.

The starting point for incorporating POB limit into our plan is utilizing a resource loaded schedule that addresses the right scope of work with best estimated man-hours of proper craft at realistic level of productivity. Thus, special attention needs to be given to the quality of HUC (and T&I) work packages as well as commissioning check sheets.

Using the method presented here, we can:

• Ensure that the plan accommodates POB limit at different stages of work (if/when the POB limit changes)

• Verify if the maximum availability of each craft originally used for planning purposes satisfies the final plan. Additionally, the result of this analysis provides a day-to-day resource plan for each craft to accomplish the task in hand yet complying with POB limit

• Run and analyze different scenarios very quickly, i.e., the tradeoff between cost of utilizing a floatel and the time saved by using the vessel.

To manage POB limitations for the offshore campaign, this author uses the Primavera Project Manager application for planning purposes, which is to plan the work and resources within a POB limit. The result of this application provides a realistic view of the duration of offshore campaign. This method can be applied to any project (or specific scope of a project) where resource limitation (people and space) is a critical issue.

Schedule settings

Use an offshore calendar with seven working days per week with 12 working hours per day and no holiday. It is recommended to use only one calendar for all activities even if some of the tasks follow different calendar. Use of different calendars is possible, yet makes the process and analysis complicated. The most critical information is the number of people working per day for each activity.

It is also important to note that night shift is a further extension of the base principles discussed in this article.

Resource loaded schedule

As previously mentioned, to utilize this method, a resource loaded schedule is needed for the entire offshore campaign including transportation, installation, and HUC (hookup and commissioning) activities. Below are some key steps.

1. List all the activities related to the scope from sailaway to first oil date. The level of details should be aligned with work packages and check sheets prepared for the entire scope of work. In development of the schedule do not use any unnecessary logical relationship to prepopulate the work sequence. Assuming no workforce limitation, only reflect logical sequence of activities, sequence of systems, and adopted strategies by using logical relationship in the schedule.

For example, if two gas compressors can be commissioned simultaneously, do not stagger them in series due to resource limitation. We will utilize Primavera to level resources to POB limit. To identify the duration of each activity, make sure realistic productivity factor is incorporated. Basically, for each task, assign the right number of each resource first [Budgeted unit/Time] and then adjust the duration. Total budgeted unit is calculated accordingly.

2. Prepare a list of resources by crew. If there are resources that are not interchangeable, identify them separately as different resource, e.g., a vendor rep for gas compressor is not interchangeable with vendor rep for chemical injection module. For each resource assume a Max Unit/Time which is the maximum availability of the resource. Primavera uses this information to calculate overallocation during resource leveling process.

For this analysis, we define two types of resources. (a) Level of Effort (LOE) resource and (b) regular resource. A Level of Effort resource is a resource that is on board all the times (for planning purposes, these resources are assumed to be on board at all time which in practice can be translated to majority of the times). Catering crew, management and supervision, Operations workforce, HES crew, etc. are a few examples of LOE resources. These resources are only assigned to LOE activities.

3. Categorize resources. This helps reporting and data manipulation when analyzing the results. One grouping categorizes resource to three types as follows:

• “LOE”: LOE resource which can only be assigned to LOE activities

• “Others”: A resource that is only assigned to non-LOE activity

• “Agg”: A dummy “Aggregated” resource which is only assigned to non-LOE activities and is used for resource leveling to manage POB limit.

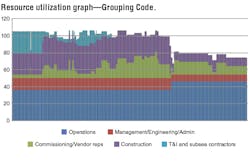

All resources except “Aggregated” resources are also grouped in following categories. These categories can be customized based on the preference. In our example, we grouped the resources to:

• Operation

• Management/engineering/admin

• Commissioning/vendor reps

• Construction

• Transportation and installation/subsea.

LOE activities and resources

As explained, an LOE resource, is a resource assumed to be onboard all the times. Configuration of LOE resources (the mix and/or the number) varies from time to time. For example, Operations crew is a LOE resource, however, the number of Operations crew is much smaller during T&I activities and it grows as the level of commissioning activities increases. To incorporate this logic into our plan we need to define distinct LOE activities in the schedule that clearly identify different stages of offshore campaign.

It is important to note that LOE activities shall be distinct with no overlap at any time as activities move due to resource leveling effort. Properly defined milestones are crucial to this process. LOE resources are only assigned to LOE activities.

Aggregated resources

To manage POB, we need to level resources. However, leveling all resources only facilitate to plan activities to manage the maximum availability of each resource (Max Unit/Time in resource list). To use resource leveling for managing POB, we need to define a dummy resource which, here, is called “Aggregated” resource (aka consolidated resource). For each LOE activity, an “Aggregated” resource is introduced. In the example presented here we have define two Aggregated resources in resource list.

Aggregated resources are only assigned to non-LOE activities that are under the scope and boundary of each LOE activity.

The Budgeted Unit/Time and consequently the Budgeted Units for “Aggregated” resource is equal to the total of pertinent Budgeted Unit/Time and Budgeted Units of other resources for the specific tasks (Duration shall be the same).

Resource leveling priority

Once all aggregated resources are assigned to activities, it is time to identify the resource leveling priority. This is where we identify which tasks should be levelled first and gets priority for utilizing resources. By resource leveling on “Aggregated” resources we will let Primavera to stagger activities due to POB limitation. But the question would be: which activity should be levelled first? To answer this question and to facilitate this process in Primavera, we need to define leveling priority for each activity:

• First measure for leveling priority: (a) Top (b) High (c) Normal (d) Low (e) Lowest

• Second measure for leveling priority: Any sequence of numbers depending on the number of activities in the schedule, i.e., 1 through 50

Finalizing leveling priority for each task is an iterative process. First assign “first measure” to each task. If the objective is to minimize the overall duration of HUC activities and/or earliest First Oil milestone, one approach is to categorize activities based on total float time. Group the range of total float time to five categories and assign first measure to each group. Then assign “second measure” as a sequencing medium to define priority within each category. With this logic, all critical activities [to First Oil] become “Top” and by sorting them based on start date, the first critical task become “1,” the second become “2” and so forth. This method of setting priorities could be a good starting point and considered as the first iteration. Obviously, if there are other considerations other than targeting earliest first oil date, we need to incorporate that into the plan by adjusting the leveling priority among activities.

Max unit/time

As described before, to manage POB limit, only “Aggregated” resources are leveled. Before we start conducting resource leveling to manage POB, we need to introduce “Max Unit/Time” for all “Aggregated” resources. How is “Max Unit/Time” calculated for each “Aggregated” resource?

Manning on an offshore facility is determined by lifesaving equipment, berthing and sewage capacity. However, to utilize the maximum accommodation capacity on the platform, the allowance shall be requested from regulatory agency which may or may not be granted as desired depending on the facility design and configuration.

In the example provided here, it is assumed that the allowance to utilize full accommodation is granted. Other assumptions as following:

• Living quarters with the berthing capacity of X number of people

• Temporary living quarters with the capacity of Y. This temporary accommodation can exist through HUC activities before COI (Certificate of Inspection) until hydrocarbon is introduced into the system. For this scenario, it is assumed that manning reduction takes place at introduction of Buyback Oil.

• Lifesaving boats on each side of facility with the total capacity of Z where Z≥(X+Y). Note: Z-(X+Y) is the limit for day time visitors.

Based on the capacity for accommodation prior to COI, the number of people on board is limited to the total capacity of X+Y. Per the regulation, in this example the limiting factor after COI is the capacity of lifesaving boats on one side of the facility. Thus, after COI, the POB decreases to Z/2. Therefore;

POB limit before COI = X+Y

POB limit after COI = Z/2

The maximum availability of each “Aggregated” resource [which is associated with each LOE activity] is calculated based on the remaining capacity which is the difference between POB limit and total number of people assigned to LOE activities.

Before conducting resource leveling, these calculated values for maximum availability shall be plugged into “Max Unit/Time” in terms of [hours/day] for each “Aggregated” resource.

Note: before conducting resource leveling, total number of resources (crew size) for each activity needs to be controlled whether it is less than the remaining capacity of the pertinent LOE resource. If there is a case that does not satisfy this rule, we need to make a trade-off between duration and crew size by keeping activity total budgeted man-hours intact. Otherwise during the resource leveling exercise, Primavera will not be able to move the activity to honor the POB limit.

Resource leveling

The last step in the process is to level only “Aggregated” resources. This can be accomplished using “Level Resources” window. However, if there is scarce, indispensable, and irreplaceable resource involved in more than one activity, we need to include them during leveling process. One example could be a vendor representative that is involved in commissioning of multiple packages or systems. In this case, the resource shall be included in resource leveling exercise in addition to “Aggregated” resources. It is suggested to limit the resource leveling exercise only to “Aggregated” resources to prevent underutilization of allowable POB limit. For resource leveling, use “Select Resources...” button, check only aggregated resources for resource leveling exercise.

Now it is time to start resource leveling and revise priority settings for tasks to reach the objectives and desirable plan. As pointed out, this process is an iterative process. Activity Detail window showing the relationship with “Critical” and “Driver” fields helps us to track activities and find out why and how activities are moved due to resource levelling effort.

Results

After few iterations of resource leveling by changing leveling priorities, we reach an acceptable plan that not only satisfies POB limit but also accommodates the planning objectives (i.e., earliest first oil date). Now it is time to extract, analyze and demonstrate the results. The source of information for results is “Resource Assignment” view. (Both Y axis for No. of People and X axis for Time in charts presented here has been intentionally eliminated. The objective is to demonstrate the idea rather than presenting exact results for the sample plan provided.)

By transferring the data to a spreadsheet and drafting a graph, we can demonstrate how POB limit has been satisfied with levelling all “Aggregated” resources. As suggested, categorizing resources are helpful for reporting purposes.

Conclusion

Many planners develop a schedule for offshore activities based on their experience without paying thorough attention to POB limitation and resource availability. Even, if they consider POB limitation, it is an exercise outside of schedule and at high-level. This method manages POB limit using the detail schedule and thus, the final plan (after resource leveling) can be used for day to day planning purposes.

Another benefit of conducting this exercise is running different what-if scenarios without re-defining leveling priorities. Leveling priorities are the logic for resource leveling and once they are set, there is no need to change them unless there is a change in the logic or adding activities to the schedule.

What-if scenarios such as changes in productivity or utilization of accommodation vessels are very helpful in communicating risk and trade-off between cost and schedule with management.

Productivity can be adjusted by changing the duration. Since activities are set as “Fixed Units/Time”, change in duration will change the total budgeted hours for each task.

Utilizing a floatel will increase the POB limit. Once Max Availability for “with Floatel case” is calculated, the new numbers shall be plugged in to “Max Unit/Time” in terms of [hours/day] and conduct the resource leveling.

This method also verifies the assumption we made for maximum availability of each craft (“Max Unit/Time”). For each resource, we initially assumed a “Max Unit/Time” and with the result of this exercise, we can verify whether “Max Unit/Time” satisfies the adjusted plan by looking at resource usage profile.

The benefits of this exercise can be summarized as follows:

• It provides a realistic offshore campaign plan that satisfies POB limit and prevent any underestimation of time and resources required to execute the work.

• It facilitates advance resource plan prior to start of the work and a daily work plan for each resource during the execution.

• It facilitates conducting what-if analysis, i.e., evaluating different level of productivity or utilization of a floatel.

It is emphasized that the quality of the results is highly dependent upon the quality of commissioning checklist and T&I work packages regarding required resources (craft mix and number) and the factored productivity.