Philippe Lavagna

SBMOffshore

The offshore industry has many leases in the western Gulf of Mexico (GoM) where there is little infrastructure and the FPSO concept can be economically competitive. There are several reasons why an operator may opt to select an FPSO concept in the GoM.

First, an FPSO offers the lowest "regret cost" in case of subsurface surprises because it can be easily moved to a new location. This is especially important for fields that are plagued with high subsurface uncertainty.

Secondly, an FPSO can offer a lower capex due to the use of shuttle tankers (which can be leased) in comparison to a new oil export pipeline. This is especially important if a prospect is not close to existing pipeline infrastructure.

Third, an FPSO is a versatile concept because it offers a large deck space and can accommodate future expansions of process facilities. This is important if the operator wants to keep the initial investment low while keeping the option of future expansions.

In addition, a disconnectable FPSO mitigates the risk of hurricane damage because the vessel can sail away from the storm.

As part of concept screening/appraisal of new GoM deepwater fields, BP retained SBM Offshore to evaluate existing disconnectable FPSO options with focus on the vessel turret, the disconnectable system, and potential riser solutions. In deepwater, the mooring and riser systems have to be optimized together, since the mooring system selection drives the riser design and vice versa.

The study was based on a typical deepwater prospect in the western GoM. The field assumptions are that the development would be comprised of 12 subsea wells in 6,200 ft (1,890 m) of water. The flowlines are assumed to be nominal 8-in. pipe designed to 7.5 ksi. Although the field would have a mud-line shut-in pressure in excess of 10 ksi, it is assumed that the design pressure of flowlines and risers can be lowered by deployment of a high integrity pressure protection system (HIPPS).

On the other hand, the potential requirement for high pressure (and high volume) water injection was also part of the evaluation; i.e., the water injection riser would have to be designed for pressures exceeding 10 ksi. The subsea architecture is composed of two loops (with two manifolds in each loop) connecting to the FPSO facility via four risers. The small amount of produced gas would be exported via a nominal 6-in. pipeline and export of the produced oil would be via shuttle tankers.

The emphasis in the concept evaluations was on cost-effective alternatives to hybrid risers; i.e. evaluating turret and mooring systems which would make the steel catenary riser (SCR) or its variations feasible. Two disconnectable mooring concepts and associated riser systems were considered:

- An internal turret system, referred to as "buoy turret mooring" (BTM) coupled with Lazy Wave SCRs

- An external turret system, referred to as "MoorSpar" coupled with SCRs.

Prior to recent developments in deepwater mooring technology, the hybrid riser concept was the only solution available with disconnectable FPSOs. However, compared to SCRs or Lazy Wave SCRs, the hybrid riser concept has a more complex design, requires more hardware, requires heavy installation vessels, and is more capex intensive. The prize in the two solutions proposed is savings in the cost of the riser system at the expense of an incremental increase in the cost of the mooring system.

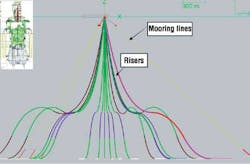

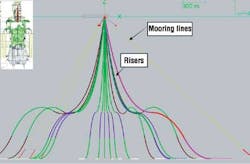

Internal turret FPSO: BTM with Lazy Wave SCRs

The BTM concept is comprised of an internal turret FPSO supporting a disconnectable buoy. The buoy is designed to support the mooring lines and risers/umbilicals upon disconnect. The buoy will slowly descend in the water column to an equilibrium condition (roughly 60 m, or 197 ft, below the sea level) where there will be minimal wave kinematics. The advantage of this concept is that all critical equipment (e.g. the swivel stack) are kept on the turret while the buoy is kept simple and its main functionality is to offer buoyancy in the disconnected scenario.

In connected scenarios, as the riser hang-off points move (heave, pitch, and roll) with the vessel, the decoupling of the vessel motions from the riser touchdown point (TDP) is achieved by utilizing distributed buoyancy in each riser and umbilical to create the Lazy Wave shape. Another beneficial effect of the distributed buoyancy, compared to the SCR, is that it reduces the riser payload on the BTM buoy when disconnected.

The main limitation of the BTM concept is related to the riser and mooring payload which drives the size of the BTM buoy, especially in deeper water. In order to limit the payload of risers, the solution is to keep the Lazy Wave location at a shallow depth below the sea level. In deeper waters, this approach leads to an increased demand for buoyancy (hence higher cost) and a much larger footprint of the riser system on the seabed. As for reducing the payload of mooring lines, the proposed solution is to use polyester lines with spring buoys.

Another BTM technology challenge is the disconnect and reconnect mechanism of a large buoy to the FPSO, which can have a displacement in the range of 3,000-5,000 m tons (3,306-5,511 tons). The choice of a BTM must therefore consider that its connect/disconnect physics places limits on its maximum displacement and riser payload. The main issue during disconnect is the relative heave motion between the buoy and the vessel; and ensuring that there is no impact between the two floating bodies after the buoy separates from the turret. As for the reconnect, the main issue is the relativley high pull-in load and design of the pull-in system. The goal was to design a pull-in system that does not limit the reconnect operation to very low seastates

BTM with Lazy Wave SCRs: conclusions

Based on the study results, it was concluded that the BTM concept with Lazy Wave SCRs is feasible for application in deepwater GoM. Specifically, the following conclusions were reached:

- Assuming a field life of 20 years, it was shown that the 8-in. production risers and 6-in. gas export riser have adequate fatigue lives in their Lazy Wave configurations. It was noted that almost all of the fatigue damage on risers would occur while the vessel is connected; and there is very little wave action on the buoy in the disconnected scenario.

- A critical aspect of design is related to the time that the buoy disconnects from the vessel; i.e., when the riser porch is exposed to a sudden drop in elevation (of roughly 50 m, or 164 ft, in less than 30 seconds). The study numerical results showed that the buoy could disconnect in the 100-year winter seastate (significant wave height of 8.8 m, or 28.8 ft) while avoiding impact with the vessel. Although the confidence in the numerical results is high, more detailed analyses and associated model testing will be required as part of design.

- The feasibility to design a quick connect and disconnect (QCDC) system for the 7.5 ksi production risers was established. Such systems can disconnect the buoy from the vessel in minutes. For higher riser pressures, QCDC systems were not available at the time of the study (Post study note: connector/retractors assembly that use Grayloc technologies are being designed for 15 ksi 8-in. and will be tested in 2012).

The proposed BTM concept combines the historical experience of several prior FPSO projects with steel risers:

- TheBC-10 FPSO, operating since 2Q 2009, combines the use of Lazy Wave SCRs from an internal turret in environmental conditions similar to the deepwater GoM

- TheWhite Rose FPSO with BTM, operating since 2002, uses QCDC and a similar interface between the BTM buoy and the turret, and also a similar disconnect pull-in system

- The BP FPSOs:Schiehallion, Skarv, and Quad 204 have turrets that use multi-bogey design.

In addition, the experience of various steel riser projects is benchmarked against the feasibility of deployment of steel risers from FPSOs in different regions.

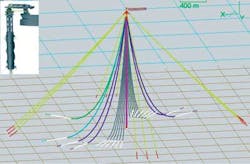

External turret FPSO: MoorSpar with SCRs

The MoorSpar is comprised of a spar type buoy to which the FPSO is connected via an articulated yoke system. The yoke system has two functions: (1) it decouples the FPSO heave/pitch/roll motions from the SCR friendly spar buoy, and (2) it is used to disconnect the FPSO from the spar buoy. This type of external turret allows the steel risers and umbilicals to be in a simple catenary configuration. In order to ensure safe disconnect of the yoke from the spar buoy, a counter weight lifts the yoke upon disconnect. A similar yoke/column technology, albeit always connected, was used over 30 years ago to safely moor the world's first FPSO offshore Spain in the Mediterranean Sea. Inline swivels (one set per axis of articulation) in the piping system were also used at the time, since flexible pipe technology was not yet available. Subsequently, many different types of column/yoke permanent mooring systems have been used in the industry.

One of the main advantages of the MoorSpar concept is that it enables the use of steel risers in the conventional simple catenary configuration. In this concept, the equipment that is typically placed on a turret will be placed on the spar buoy, including the swivel stack and the subsea chemical distribution system. Hence most of the FPSO storage will be available for cargo and most of the FPSO deck area will be available for topsides process systems. The equipment that are placed on the spar buoy are designed to be above the water and away from wave impact loads. The QCDC equipment will be at the yoke level, above the water at all times, and can be visually checked after the disconnect process. The production QCDC equipment have a low pressure rating because these are downstream of the HIPPS protecting the swivels.

As with the internal turret BTM concept, when a hurricane approaches, the FPSO will disconnect from the MoorSpar and sail away to safety. The yoke design is such that it will lift itself away from the buoy which remains at constant draft. The current design is based on the support of a dedicated standby vessel (for safety reasons, since deepwater FPSOs are far awayOffshore) which will follow the FPSO during the escape from the hurricane. This standby vessel is then used to assist the FPSO in reconnecting to the MoorSpar buoy in seastates up to significant wave height of 3 m (9.8 ft).

MoorSpar with SCRs: conclusions

According to the results of the study, the MoorSpar with SCR concept was confirmed to be feasible for the deepwater GoM FPSO application. A number of conclusions were reached regarding the MoorSpar concept. These are detailed below.

The concept is SCR friendly because the spar buoy offers a low motion (and especially low heave) platform for riser hang-off. It is especially suited to fields where the riser payload can be significant or somewhat uncertain, because the spar buoy design can accommodate a large range of riser payloads. This situation may arise from a large number of risers, or from high pressure risers in ultra-deepwater.

A permanently connected mooring/yoke system with heavy duty articulations (such as hinges and gimbal tables) combined with a fluid transfer system and pipe swivels was used offshore Tunisia from 1982 to 1996. A similar disconnectable mooring/yoke system is considered to be new technology and hence was qualified with model testing.

The combination of mooring lines and tethers for the spar buoy represents new technology. On the other hand, the design can be modified such that tethers would not be required and this design alternative would represent a conventional deepwater floater design.

In the MoorSpar concept, special attention should be paid to the equipment that is placed on the spar buoy and the requirement for maintenance of such equipment. Ideally, the spar should be viewed as an unmanned facility which is accessed by personnel only when necessary. The reason is that in the connected mode, access from the FPSO to the spar buoy is weather dependent and would not be available at all times.

Concluding thoughts

The study described here concluded that both internal and external disconnectable turret concepts are feasible in the GoM, and that the maturity of their technologies is generally well proven. A major objective of the study was to determine if SCRs, or Lazy Wave SCRs, could be used in conjunction with disconnectable FPSOs, thereby avoiding the high cost of hybrid risers. The study concluded that:

- An internal turret BTM type FPSO can support a limited number of Lazy Wave SCRs with an adequate fatigue life

- An external turret MoorSpar type FPSO can support a virtually unlimited number of SCRs without the need to use Lazy Wave configuration

- A limitation of both FPSO concepts is related to high pressure water injection. Current swivel technology is around 7 ksi pressure limit. New swivel designs are becoming available that can increase the pressure beyond 10 ksi. A 12-in. swivel rated at 12 ksi prototype has been built and will be qualified in 2012.

In general, the internal turret disconnectable FPSO is more suited to deepwater fields with fewer risers and umbilicals, because a high payload for risers and umbilicals would require a large size buoy. On the other hand, the external turret MoorSpar concept is more suited to deepwater fields with a large payload (either due to a large number of risers and umbilicals or due to ultra deepwater/high pressure risers), i.e. because the spar can be designed to accommodate a significantly larger range payload.

In the deepwater Gulf, a disconnectable FPSO concept provides the industry with several advantages such as:

Acknowledgment

Based on a paper presented at the Deep Offshore Technology International Conference & Exhibition, held in New Orleans, Louisiana, Oct. 11-13, 2011.

Offshore Articles Archives

View Oil and Gas Articles on PennEnergy.com