Service providers working on next generation of multi-zone systems

Bruce Techentien •Stephen Ingram •Andreas Grossmann

Halliburton

The Wilcox formation in the Lower Tertiary is an interesting and challenging development. The industry is currently seeking ways to increase efficiencies, increase production, and optimize performance of this reservoir.

With regard to Lower Tertiary wells, operators sometimes assume that they are similar to the Wilcox formation in South Texas. However, studies indicate these wells should be treated like other Gulf of Mexico (GoM) wells, and they do require sand control. Is the industry willing to take these technical development risks? If unique solutions are proposed, what preparations are necessary, and how should planning proceed?

There are unique solutions that operators can apply to the deepwater GoM as well as alternative solutions, processes, and procedures developed for land applications that can be adapted to the deepwater GoM. Land production has adopted the horizontal approach for efficiencies, but is this the correct approach for deepwater? The multilateral approach is an interesting option that has been applied in other offshore environments, but is this a concept adaptable for the Lower Tertiary? How can monitoring and control be applied to these two concepts from land applications? How do operators take industry knowledge and apply it to the unique offshore environment of deepwater and subsea completions?

The goal here is to examine these questions and initiate the thought process of how the industry can optimize the returns from the Lower Tertiary by increasing production and recoverable reserves through technology and reservoir management.

Lower Tertiary

The Lower Tertiary is located approximately 175 mi (280 km) offshore, estimated at 80 mi (125 km) wide, and as much as 300 mi (480 km) long. Water depths are from 5,000 to 10,000 ft (1,525 to 3,950 m). Production targets are at depths of 10,000 to 30,000 ft (1,525 to 9,140 m) subsea.

The Tertiary trend dates from 66 to 38 million years. Within the Lower Tertiary, the lower Wilcox portion is sheet-to-amalgamated sheet sands considered to be part of a regional basin floor fan system. The late Paleocene to early Eocene (Wilcox equivalent) reservoirs are considered to be laterally extensive sheet sands that were deposited in deepwater. These reservoirs are distributed across an area largely covered by the allochthonous Sigsbee salt canopy. This canopy causes extra problems beyond just the water depth and well depth required to reach the reservoirs.

These exploration plays depend on understanding of the updip fluvial/deltaic stratigraphic architecture and the potential for partitioning of reservoir-quality sandstones across the depositional shelf into the slope and basin floor environments.

The Lower Tertiary is estimated to contain up to 15 Bbbl of oil compared to current US Energy Information Administration estimated proven reserves of 36.5 Bbbl as of December 2013. It is estimated that potential reserves of close to 5 Bboe have been discovered to date. The 15-Bbbl prize comes at a huge price, with drilling and completion costs of approximately $200 million per subsea well.

Multizone completions

Currently in the Lower Tertiary, the industry predominantly uses the generation IV multizone completion system. This completion approach allows the operator to perforate the entire interval in a single trip, deploy the sandface completion equipment, frac each zone in a second trip, and then run the upper completion. Operators have estimated this completion approach has saved on an average 20 days of completion time in a four-zone completion. With this technology, the individual intervals are commingled for production. This approach has proven to be successful for many GoM operators.

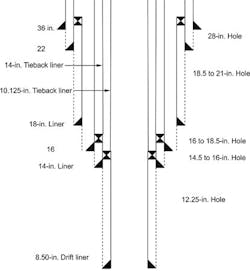

As industry knowledge of the Lower Tertiary increases, so have the demands of the completion system. Service providers have been working on the next generation of the multizone completion system for the Lower Tertiary: generation V. The basic requirements are a higher pressure-rated system, monitoring, and control. Other considerations are higher frac treatment rates, more proppant per zone, and deeper wells. The basic well construction has not changed. The primary casing through the pay zone is an 8.50-in. drift casing (6.50-in. drift or 6.0-in. drift as a contingency) and tied back to the surface with a 9.50-in. drift by 8.50-in. drift tieback liner.

Differential pressure rating

When the generation IV system was developed in the mid-2000s, it was determined that a gravel pack system with a 10,000-psi differential rating was acceptable. The high differential ratings for production was handled by leaving the gravel pack system balanced, and the upper completion would handle the higher differential rating of production. There are several factors that are driving operators and designers to a higher differential pressure rating, such as higher pump rates (resulting in higher friction losses), deeper wells (resulting in additional pipe friction), depleted zones within a reservoir, and individual production of zones of intervals within a given reservoir. With these requirements in mind, there are at least two service companies currently developing multizone gravel pack systems with a target differential pressure rating of 15,000 psi. The inside diameter (ID) of these systems (designed for 8.50-in. drift casing) is 5.0 in. ±0.25 in. (depending on the service company). This design should provide an additional 50% safety factor for collapse rating during frac treatments or depletion for production or stimulation.

Monitoring and control

With the current configuration (generation IV or V), there are two discrete options for zonal control: a shrouded interval control valve (ICV) type of intelligent completion with a production string inside the sandface completion to separate flow and ICVs above the sandface for control; or ICVs inserted within the sandface completion.

In the first case, a production string is run into the sandface completion and seals off between the two intervals. The lower zone is produced through the isolation string up to a shrouded ICV and into the production tubing. The upper zone is produced through the annulus between the sandface completion and the production string, past the shrouded ICV, into an upper ICV, and into the production tubing. This type of completion limits the zonal control to only two intervals.

The second completion incorporates ICVs that are run within the ID of the sandface completion. This completion approach allows for zonal control by each ICV that is run in the completion. This approach has been taken in multizone completions (8.50-in. drift casing) in Southeast Asia for as many as six zones in a single well. The ID restriction of the 8.50-in. drift system limits the outside diameter (OD) of the ICVs to the use of 27⁄8-in. ICVs with a 2.31-in. ID, which is not accommodating to the production rates for the Lower Tertiary.

The next challenge to ICV use in either configuration is the pressure rating. Currently, the maximum pressure ratings for these valves vary between 7,500 psi and 15,000 psi. The industry is currently working on a 3½-in. shrouded by 4½-in. ICV system that is fully 15,000-psi rated and qualified for Lower Tertiary conditions. There are plans to upgrade the 27⁄8-in. ICV to a 15,000-psi rating; however, it will not meet the production requirements.

Casing design

As demonstrated in the previous discussion, the desire to increase the differential pressure rating of the multizone systems can be accomplished. The ability to achieve monitoring and control of the individual zones can also be achieved. With the current casing design being deployed in the Lower Tertiary, the designers have reached an impasse. Working from the inside drift diameter of the casing (8.50 in.), the designer must take into account: the industry-accepted radial clearance between casing and screen; the screen filter depth; a flow path below the screen; screen basepipe; and the thickness of the flow control equipment. Working from the outside in (casing to flow path) and the inside out (flow path to casing), it is clear there is an overlap and potentially a compromise of some desired requirements.

With this in mind, one could wonder is the existing casing design cast in stone? Could the production casing be changed to 10¾-in. or even 135⁄8-in. casing? The larger casing ID would allow for a larger ID of the sandface equipment, resulting in a larger ID of the flow control equipment, and thereby accommodate the desired injection or flow rates and pressure ratings.

There are challenges associated with this concept. Can the wellbores be drilled to depth with the required hole size that drilling technology is continually improving? Can a casing design be effectively developed to address current and future regulatory requirements and meet the ID requirements for the larger completion? Is the additional cost of the new casing design worth the added value that it brings?

Openhole completions

At least one service provider has developed, tested, and successfully deployed an openhole multizone gravel pack system. The current generation IV openhole system was developed as a contingency for the 8.50-in. drift casing ID multizone system. This openhole system has also been considered as a method for reducing current completions costs. The openhole system shows some real promise for the generation V multizone system.

In the current drilling approach for many of the Lower Tertiary wells, the operator drills out of a 14-in. or 135⁄8-in. casing with a 12.25-in. hole. Once total depth (TD) is reached, a liner is deployed across the pay zone and a tieback liner run, connecting the production liner to the wellhead. One alternate solution is to deploy a generation V multizone system in the 12.25-in. open hole instead of the production casing. Next, the tieback liner is run to connect the casing back to surface. With this design, the only change involves replacing the casing string across the production interval with a completion system. By running the sandface completion system in a 12.25-in. wellbore instead of an 8.50-in. wellbore, the system designers can develop a system with higher pressure ratings, higher frac ratings, and higher production rates and still accommodate monitoring and control of the wellbore without restricting production.

One restriction of any level of multizone systems is the ability to address the issue of different pressure gradients in the zones being perforated and treated. Typically, wells can be drilled with much higher differential pressures between zones than they can be perforated. With this in mind, it is possible to use the unique attributes associated with drilling muds to address issues with high-differential pressure ratings between zones within a given interval.

Unconventional completions

Almost without exception, every discussion about fracturing the Lower Tertiary begins with: “This formation is just like the Lower Tertiary in South Texas; why should it be treated any differently?” After much discussion, it is generally determined that the Lower Tertiary in the GoM should be treated much like other GoM wells with respect to the completion approach. The design ends up being a completion with screens and a tip screenout frac design with the intent of packing the screen by casing annulus. These zones are typically broken down into 100 to 300-ft interval lengths, pumping a mini-frac followed by a main frac with a tip screenout design, and a slowdown schedule at the end of the treatment to ensure a good annular pack. With the experience now gained in the industry through numerous wells, is this approach still the best solution? Do these wells really require sand control, or can they be produced with conventional fracs? Does an annular pack provide some protection, or is it not needed? Will a higher quantity of smaller fracs be more effective than a smaller quantity of larger fracs? What is the best solution?

There is the potential to move from the standard multizone completions (sand control concept) to something as simple as “plug and perf” much like is done in unconventional completions or a sleeve-type configuration. There are risks to consider with these approaches, such as addressing a premature screenout and whether the proppant is resin coated or tailed in with a resin as a form of sand control. What is the best approach?

Multilateral completions

Multilateral technology (MLT) in deepwater applications have beneficial outputs: lower capex for infrastructure; minimizing drill operations to the reservoir (lower cost and lower risk); minimizing drill operations through salt/rubble zones, such as the allochthonous Sigsbee salt canopy (lower risk); ability to target compartmentalized reserves, etc. Other MLT benefits in deepwater applications might not be so obvious but can have a great impact on the decision-making process.

One such benefit of MLT is improved recovery factor. Recovery factors of 10% are often mentioned for deepwater Paleogene fields. However, at least one operator reports those recovery rates can be increased to 20% or more using technology that has been developed for the Norwegian North Sea. One strategy that has worked well in Norway is the drilling of multilateral wells. While water depths in the Lower Tertiary are far greater than those in the Norwegian North Sea, there is no reason one cannot drill multilateral wells. The technique can help reduce the overall cost of drilling programs in the Lower Tertiary in which drilling and completion of a single well can cost $200 million to $300 million.

While there have been no known applications of MLT technology in deepwater Paleogene applications, a US Department of Energy-sponsored study indicates multilaterals should be explored as an improved oil recovery technique for the Paleogene (RPSEA 07121-1701 2010).

It is known from other large-scale subsea applications (e.g., in the North Sea) that recovery rates have been dramatically improved through multilateral well design - in some cases, up to 40%. The current recovery rate in the Troll field for oil is 40% with a goal to reach 52%, while the global average recovery factor is about 35%. Most of the wells are so-called branch wells, which mean they have two or three horizontal sections that are gathered at a crossroad in the reservoir. Elsewhere, these wells are referred to as multilateral wells. It is thought through this technology that productivity gains are mainly driven by lower drawdowns and better manageable production regimes.

Reliability of MLT

Multilateral wells have been routinely drilled for several applications onshore and offshore for many years. While in the 1990s and early 2000s MLT was still mostly of an experimental nature, it has now largely become a recognized technology with close to 2,000 junctions installed worldwide. Equipment is much more robust and reliabilities are equal to other completion technologies.

According to one study (Butler, et al., 2015), the current systems of one service company have overall reliabilities ranging from 93 to 99.6% with the reliabilities trending toward 100%. This increase in reliability has developed with an increase in installation efficiencies of the technology even as the complexity of the applications has increased dramatically. In fact, some of the most complex applications (subsea and multiple junctions in the same wellbore) have the highest reliability rates. The sample size in the reliability study included more than 900 data points.

It is now common practice to complete wells with three to five laterals. Laterals are several thousand meters long, production regimes can be intelligently controlled for each lateral, and stimulation treatments, including hydraulic fracturing can be performed.

Deepwater challenges

While most multilateral installations today are relatively deep in terms of measured depth, they do not require high-pressure/high-temperature (HP/HT) ratings. Currently, the maximum MLT junction pressure rating is approximately 50% of the deepwater completion systems. Current MLT systems can handle up to 7,500-psi differential pressures; they can also be run in conjunction with gravel pack systems. Tying in fracs or frac packs would be the next logical step. However, that would also require the ability to handle higher pressures.

The majority of current MLT systems are deployed in 95⁄8-in. or 10¾-in. mainbore casing; however, with the requirement for higher pressure ratings, the ID through those junctions is limited and likely not large enough to accommodate the required flow rates. Therefore, MLT junction systems require further development to withstand those HP/HT conditions and at the same time offer large enough conduits.

Precise depth and orientation control for accurate placement and orientation of tools and equipment across window exits are essential and have to be addressed because there are no useful surface indications at these depths. Developments have taken place to use wall-mounted telemetry in those completions applications. Tools have already been validated and commercialized in subsea applications in the North Sea.

Further, the multilateral junction(s) will likely have to interface with intelligent completions to realize the wellbores’ full potential as alluded to in the monitoring and control section above. Rotation for placement or orientation correction will hence be limited, presenting technology design and installation challenges.

Milling windows for multilaterals in deep wells is perhaps the greatest MLT challenge to overcome. The issues mainly involve controlling weight and torque on the mills and milling debris cleanup. In a deepwater environment with expensive rig rates, milling reliability and well cleanout will have to be optimized. Conceptual solutions exist, but the technology will have to be fully developed and validated in the field. The continuation of real-time downhole “weight on bit, torque on bit” technologies are narrowing the working envelope of this challenge to a more manageable task.

Unconventional lessons

The unconventional play has transformed the energy landscape financially, politically, and technically. As onshore reservoirs drove toward lower risk and predictable financial returns following the industry downturn of the 1980s, the industry began adapting to horizontal multistage completion well development targeting lower permeability formations with large areal extent. Many of the traditional vertical sandstone assets of the 1980s, 1990s, and early 2000s are now horizontal multistage completions similar in nature to better known shale developments. Formations such as the Cotton Valley formation of east Texas, Springer formation in southwestern Oklahoma, Austin Chalk formation in south Texas, Bone Springs formation in southeast New Mexico, Niobrara formation in Colorado, etc. are lower permeability “tight” reservoirs.

Overarching to these above statements, as permeability is reduced; hydraulic fractures are required to sustain economic flow. As per Soliman (1983), production increase can be defined as the ratio of production rate after fracturing to the rate before fracturing at the same pressure differential. Production increase of a well caused by a vertical fracture is affected by propped length, propped height, width, and permeability of the fracture. In unconventionals, the additive value of fractures along a lateral wellbore defines the productive enhancement effectiveness. The design of such fractures generally follows the production increase curves represented by Tinsley et al. (1969).

Fundamentally, the term unconventional play can be categorized as a formation or reservoir having characteristics, such as porosity, permeability, or geomechanical properties, which in combination require multiple hydraulic fracture stimulation treatments to deliver an economic return of produced hydrocarbon. Following this set of criteria, optimization of that financial return has led to the horizontal well application, followed by technology advances to enhance the effectiveness and efficiency of the hydraulic fracturing service enabled by advances in completion technology and methods.

Today’s unconventional completions throughout the world have a similar appearance. However, the differences are reflective of reservoir properties and reservoir fluid type influencing the fracture system (fluid system, chemical additives, and proppant type); fracture design (volume and rate); perforation spacing, fracture spacing, wellbore spacing, casing system (pressure rating, diameter, and strength); formation depth, formation pressure, and formation closure (listing not comprehensive). Additionally, differences are reflective of the completion method i.e., plug and perf, sleeve systems, hydro-jet perforated, cemented and uncemented laterals, and openhole completions.

To manage this step-wise change from the 1980s to today, supply chain infrastructure and logistics must be mentioned as major enabling factors by which unconventionals have delivered such increased production to market. By sea, rail, and truck, sourced materials to support horizontal multistage completions are required by the industry to maintain costs at a point of financial viability for these reduced permeability reservoirs. Increased materials and service intensity must be considered as critical components to any asset or project.

What can be learned by the impressive advancements of the unconventionals? It would stand to reason given the Lower Tertiary’s reduced permeability as related to the historical GoM-producing formations (Pliocene and Miocene formations) that increased fracture density enabled by horizontal wellbores located through the pay would deliver increased economic return. Identification of “formational sweet spots” delivering these horizontal wells with multistage hydraulic fractures would maximize well economics and recoverable reserves. Delivery of multilaterals targeting the specific vertical portions of this normally thick reservoir would additionally deliver positive economic benefit. These statements have born true onshore in the unconventional arena and are technically sound in principle; their applicability to the Lower Tertiary is therefore a function of safety, risk management, commodity price, technology advancement, and logistics.

Conclusions

The completions of the Lower Tertiary with the existing generation IV multi-zone completion systems have been successful. But as the industry moves forward and industry requirements increase, these completions will become more complex. The service providers are currently developing the generation V multizone completion system, which will increase the differential pressure rating from 10,000 psi to 15,000 psi. The service providers are also working on a means of monitoring and controlling production with this next-generation system to improve efficacies and production.

In addition to working within the known parameters of the Lower Tertiary completions, it is the authors’ belief the industry needs to expand their horizons to enhance these completions to increase production and optimize performance of these wells. Is the casing design optimal for the desired completion approaches? Is the conventional approach for GoM completions the correct approach? Will the use of multilateral completions impact the overall cost of the completions while providing zonal control and optimizing production? It makes sense to review what has been learned from onshore unconventional completions and understand how these learned lessons can be applied to the deepwater GoM.

Once a completion approach or a set of completion approaches are agreed upon, it will take time to develop these concepts. It is reasonable to assume that a major step change in the completion approach of the Lower Tertiary will require as many as three years to develop. If the industry needs a solution by 2020, now is the time to establish the parameters for these new concepts and dedicate the resources to resolve these challenging solutions.

References

1. Soliman, M.Y. 1983. Modifications to Production Increase Calculations for a Hydraulically Fractured Well. J Pet Technol 35 (01): 170-172. SPE-9021-PA.http://dx.doi.org/10.2118/9021-PA.

2. Tinsley, J.M, Williams, J.R., Tiner, R.L. et al. 1969. Vertical Fracture Height-Its Effect on Steady-State Production Increase. J Pet Technol 21 (05): 633-638. SPE-1900-PA.http://dx.doi.org/10.2118/1900-PA.

3. Grieser, B., Hobbs, J., Hunter, J. et al. 2003. The Rocket Science Behind Water Frac Design. Presented at the SPE Production and Operations Symposium, Oklahoma City, Oklahoma, USA, 23-25 March. SPE-80933-MS.http://dx.doi.org/10.2118/80933-MS.

4. Kliewer, G. 2011. Lower Tertiary remains an important exploration zone. Offshore 71 (6): 46.

5. Butler, B., Grossmann, A., Parlin, J. et al. 2015. Overcoming the Perceived Risk of Multilateral Wells. Presented at the SPE Offshore Europe Conference and Exhibition, Aberdeen, Scotland, UK, 8-11 September. SPE-175437-MS.http://dx.doi.org/10.2118/175437-MS.

6. RPSEA 07121-1701, Development of a Research Report and Characterization Database of Deepwater and Ultra-Deepwater Assets in the Gulf of Mexico, including Technical Focus Direction, Incentives, Needs Assessment Analysis and Concepts Identification for Improved Recovery Tech. 2010. Sugar Land, Texas: RPSEA.

7. McCulley, R. 2013. Big discoveries drive Lower Tertiary exploration and development rush. Offshore 73 (6): 56.

8. Statoil News. 2015. Troll oil for 20 years!http://www.statoil.com/en/NewsAndMedia/News/2015/Pages/24Sept_TrollOil.aspx, 24 Sep 2015 (accessed 22 January 2016).

Acknowledgment

The authors wish to thank Halliburton management for their support in developing leading-edge multizone concepts and completion solutions; the deepwater operators who are at the forefront of pursuing future extreme developments that require leading-edge completion solutions to enhance project viability; and the service providers and their dedicated employees who are working to make the future of the Lower Tertiary completions a reality. This article is based on a paper presented at the Offshore Technology Conference (OTC) held on May 2-5, 2017, in Houston, Texas.