Jeremy Beckman

Editor, Europe

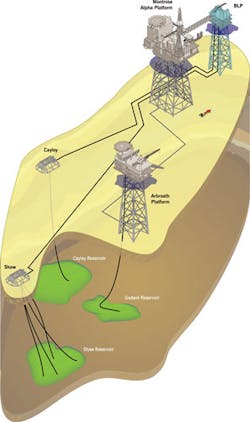

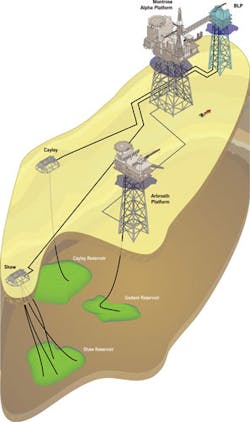

One of Britain’s longest serving platforms is set for a sixth decade of service as part ofRepsol Sinopec Resources UK’s Montrose Area Redevelopment. The renovated Montrose Alpha structure, which processes oil and gas from Montrose and other fields in the area, has also been bridge-linked to a new platform that will receive production from the Cayley and Shaw satellite developments. The program is designed to recover 100 MMboe from the area, extending the lives of facilities that would otherwise be facing decommissioning.

Amoco discovered the Montrose field, 200 km (124 mi) east of Aberdeen, in 1971 and produced first oil five years later via a fixed steel drilling, production and quarters platform (Montrose Alpha). Since the mid-1980s, the oil has been exported to eastern Scotland via a pipeline connection to the Forties system.

In 1990, Amoco modified the platform’s processing equipment and expanded its duties to reception of oil from the new Arbroath field drilling and production platform to the south. Over the next 15 years, as stewardship of the area switched from Amoco to BP to Paladin Resources, tie-ins followed of the Arkwright, Brechin and Carnoustie fields to Arbroath. Talisman Energy then took over, adding the Wood oil field to that list, installing the Wood and Gas Export (WaGE) processing/compression module at Montrose Alpha and a new 6-in. pipeline delivering gas from the various fields into the CATS offshore trunkline system.

Over the past decade, Talisman had built a reputation as a North Sea field rehabilitation specialist. During 2007-09 the company discovered oil and gas at three new fields in the area, Godwin, Cayley and Shaw, as part of an exploration campaign to add resources and extend the lives of the Montrose/Arbroath production facilities.

Work on the MonArb project, as it was known at the time, continued until 2012, when Talisman agreed to form a joint venture with Chinese oil company Sinopec to further develop its UK interests. In October that year the UK government approved the duo’s plans for what is now known as the Montrose Area Redevelopment (MAR).

“The impetus for MAR had been the three discoveries - building the resource base then growing volumes in order to monetize it,” said project manager Hugh McClure. “But at the same time we were also looking to improve production efficiency and to ensure we swept the Montrose reservoir effectively.”

To date Montrose has produced around 95 MMbbl of oil, somewhat below Amoco’s original expectations. The reservoir, like Arbroath’s, is a domed structure in the Palaeocene Forties Formation reservoir - the same horizon as the Forties field to the northwest. Permeability is poor in places, with a high shale content. Water injection to improve reservoir sweep started in 1978 beneath the oil column. Previous operators also considered reinjection of the produced gas to further assist recovery, but concluded this would not be viable.

However, a review of 4D data over Montrose’s Forties formation sandstones identified infill opportunities in channels that had not been fully swept. These oil pockets have since been matured to drill-ready prospects using reprocessed inversion products from three seismic datasets.

McClure describes the wide-ranging goals behind MAR as “a case of tying in the pieces of the jigsaw that make up the whole value pie. Part of the value is that you extend tail-end production and at the same time access new reserves that you couldn’t have developed if Montrose had been abandoned, and decommissioning was on the cards. Along the road to our decision we had evaluated various different concepts. The one we chose was a bit unusual - a brand new platform tying into a 40-year-old facility, which we knew we would have to rip the heart out of in order to make it fit for extended service.”

Cayley and Shaw benefited from the government’s newly introduced small fields allowance, but during 2013 cost pressures came to bear on MAR. “The project had been sanctioned with a particular concept and execution plan in mind,” McClure explained, “at a time when the market was hot and still rising. Some things we agreed on we would not have done now, looking back.”

Toward the end of 2014 when the oil price started its inexorable slide, shareholders and partner Marubeni North Sea got together with a view to revising the plan and the project’s execution. “They were, and have been very supportive,” McClure said. “In the end, the partners agreed to reset the project and accept the extra investment, but there were also certain things we decided not to do in order to save costs.”

One of the key decisions concerned the infill drilling program for the Montrose reservoir, intended to boost the field’s oil production to 10,000 b/d, assisted by extra gas-lift and water-handling capacity supplied from the BLP. The original plan had been for Archer to drill six wells from Montrose Alpha using a modular rig, with dry trees. Last November, however, the joint venture decided to cancel Archer’s two-year, $98-million contract. “We had to evaluate the optimum way of developing the reserves,” McClure explained, “and a temporary rig on the platform also requires a crew, associated services, and hookup operations. So we went back to the drawing board and now plan to reissue the drilling contract early next year.”

“There are two main aspects to our cost review process,” McClure said. “One involves what I would call ‘good capex’, investing and getting our money back through increased production efficiency. The other is ‘not so good capex’, spending on infrastructure such as new gratings and hand rails at Montrose Alpha. There is plenty to do in that regard, but that is the cost of doing business in this type of project.”

AMEC is the main contractor responsible for the structural upgrades to Montrose Alpha, and also for the current hookup phase. This is a relatively small production platform by early North Sea standards - larger than Arbroath’s, which is manned by a very small crew, but producing less oil. Alongside Montrose Alpha is the original development’s six-pile tripod structure supporting the flare bridge, with a cantilever at the end where the tip is. It is not the most efficient arrangement, McClure said, causing restrictions to marine operations, but it will nevertheless stay in place.

CB&I in London designed the BLP, which will have capacity to process up to 30,000 b/d of liquids and 150 MMcf/d of gas from Cayley and Shaw, and which will also provide injection water, lift-gas and chemicals to the two satellites and any other discoveries nearby that might be tied back at a later stage. OGN in Wallsend, northeast England built the 71-m (233-ft) tall, 5,745-ton jacket, which supports 12 gas risers, four j-tubes and seven caissons, while Heerema Fabrication Group in Zwijndrecht supplied the 10,500-metric ton (11,574-ton) topsides. Early this May the Heerema Marine Contractors crane vesselThialf placed the topsides on the pre-installed jacket (secured by six 2.4-m dia. piles), and also the 71-m connecting bridge to Montrose Alpha and flare boom for the BLP, both constructed by Wilton Engineering Services Ltd.

Early UK North Sea platforms were not engineered for long service lives, hence the sector’s recent issues with extended maintenance downtime. The BLP may not need to operate for 40 years, but its design covers all eventualities. “We used exotic materials such as duplex and super-duplex widely, including a lot of areas where this had not been done before,” McClure said, “so we are not expecting that facility to show wear and tear as on earlier platforms.

“Although the BLP is normally unmanned, we followed the same design criteria as for a manned platform. It has a blast wall and behind that are the hazardous and near-hazardous areas, which take you back to Montrose Alpha.

“There is nothing ‘step-out’ in terms of the technology on board. We plan to make our own water onboard for process requirements, something which is normally done on platforms only for human consumption, and we will look to offload our diesel via a different type of hose system that the company has used elsewhere. The BLP has a very sophisticated control system, with widespread cameras to ensure that our technicians don’t have to walk to certain areas unless they really need to (as they can view those areas from the control room).”

Gas will be exported via a new riser on the BLP tying into the existing gas export line to CATS at a point close to the two platforms. The capacity of the air compressors and the firewater and seawater pumps is also more than adequate for the BLP’s needs, and can therefore be shared with Montrose Alpha.

Godwin, Shaw, and Cayley are all Jurassic Fulmar Formation discoveries with varying characteristics that had to be addressed in the well designs. Godwin, discovered and appraised in 2009, is a black oil reservoir with a risk of premature water breakthrough. Gas-lift has been incorporated into the completion. Godwin began producing last year via an extended reach well drilled from the Arbroath platform.

Shaw, discovered and appraised by three wells, is a black oil discovery 17 km (10.6 mi) south of Montrose that will come onstream early next year via two subsea producers equipped to receive lift-gas from the BLP’s compression system. Shaw is expected to produce in excess of 20,000 b/d with associated gas. Here the risks are water injection sweep and uncertainty over reservoir heterogeneity and connectivity, but these should be mitigated by subsurface monitoring. This, combined with production performance, will be used to determine the location of water injector wells. The original plan had been to start up the injectors around a year after first production from Shaw, but the schedule has now been brought forward to 2017. “We don’t want to risk the reservoir pressure going down too much,” McClure explained.

Both the Shaw producers are connected to a subsea manifold tied back to the BLP via a 17-km (10.6-mi), 10.8-in. insulated production line and a 4-in, lift-gas line. The water injectors will be supplied by an 18.1-km (11.2-mi), 8-in. water line, with a 17-km control umbilical running from the BLP to the producers and from there to the injectors.

Four exploration and appraisal wells revealed Cayley, 10 km (6.2 mi) west of Montrose, to be a relatively high-pressure gas-condensate reservoir with high-salinity fluids and an associated risk of corrosion. The two subsea production wells are deviated to minimize late-life sand ingress, with water wash facilities incorporated, and equipment to receive lift-gas from the BLP if needed. “The reservoir is on the margin of HP/HT,” McClure said, “but there are no real step-out design features in the wells.” Shaw’s oil will be exported through an existing flowline into the Forties pipeline system and further to Cruden Bay, north of Aberdeen, via an existing export riser at Montrose.

Cayley’s wells are connected to another subsea manifold, tied back to the BLP via an 8½-in. pipe-in-pipe production line, a 3-in. lift-gas line and a 4-in. utility line. These are combined within a 32.5-in. pipeline bundle, supplied and installed by Subsea 7, including umbilical and chemical cores and divided into two 5-km (3.1-mi) sections. Repsol Sinopec Resources anticipates plateau gas production from Cayley of 65 MMcf/d and associated liquids - both fields could remain in production for 15-20 years.

The semisubsSedco 711 and Sedco 712 drilled all four producers for both fields over two years, while Subsea 7 manufactured and installed the pipeline bundles and other subsea facilities under a $285-million contract.

There have reportedly been other discoveries in the Montrose area, and a team from Repsol Sinopec Resources is examining other potential satellite structures. Based on current production predictions, ullage should be available in the infrastructure for another tieback in the medium term, McClure said.

“Montrose Alpha is currently shut down while our team implements changes to the emergency shutdown, fire and gas and control systems, also putting in three new main oil line pumps and a new cooling system, and the facility will remain off-line until late summer. At the same time, people are working on the BLP as part of the 12-week hookup campaign to ensure the new platform is mechanically complete. Thereafter, the focus switches to pre-commissioning and commissioning activity, all to be done while the BLP is still hydrocarbon-free. Later in the year, when we have checked all systems to our satisfaction, we will be in a position to introduce hydrocarbons into the BLP and then prepare sequentially for production from Shaw, Cayley, and then water injection.”

The next major program will be on the Arbroath platform where there will be similar upgrades to the control and emergency shutdown systems. The current plan is to complete the design next year followed by installations in 2018.