By Ariana Hurtado, Editor and Director of Special Reports

External pipeline corrosion can lead to potentially catastrophic failures, resulting in significant costs to the economy. Therefore, corrosion protection systems and technologies are critical for the offshore oil and gas industry.

The RedLineIPS SmartPad system, developed by Texas-based Cogbill Construction and pending final patent approval, was designed from the ground up to combat external corrosion in industrial piping systems, particularly at pipe support points known as corrosion under pipe supports (CUPS).

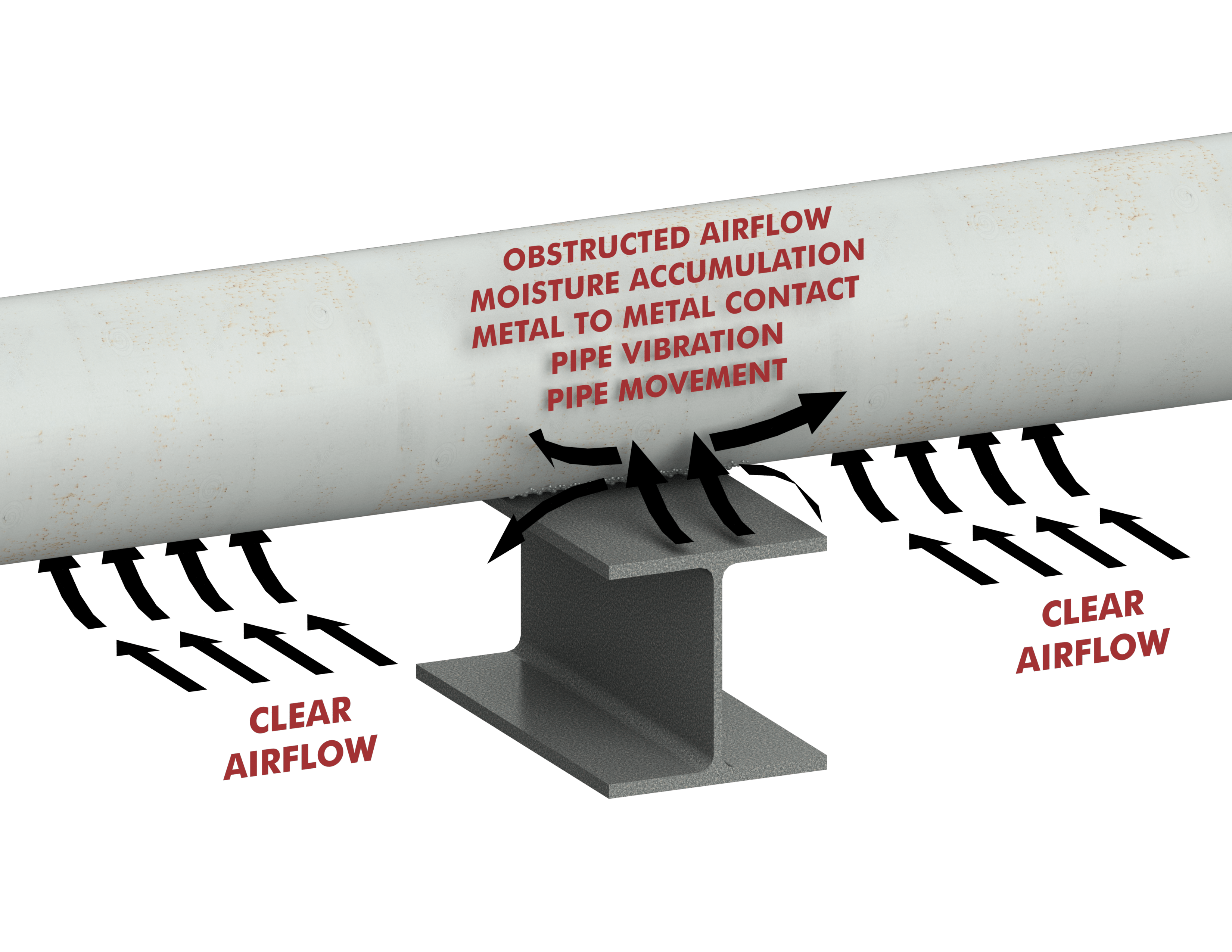

"External corrosion in pipes occurs due to the impact of friction, moisture retention and metal-to-metal contact between pipes and their supporting structures," Hani Almufti, engineer and manager with Cogbill Construction, told Offshore. "The consequences include exposure to environmental elements, galvanic corrosion and crevice corrosion, ultimately leading to pipe failure."

SmartPad also prevents water molecules from forming between the pipe and the pad with a Hydroseal NEMA-4-rated water tight gasket, eradicating conditions conducive to crevice corrosion.

"A closed-cell elastomer gasket establishes a watertight seal, preventing moisture ingress, and thus corrosion," Almufti explained.

The system also enables swift installation as well as removal for visual inspection and reinstallation, which the company says facilitates cost-effective visual corrosion inspections. The fiber-reinforced plastic (FRP) composite SmartPad is crafted from continuous strand mat laminated vinyl ester resin and is designed to ensure durability, UV resistance and effective support for pipes.

"Components crafted from FRP prevent galvanic corrosion, fortifying both the piping system and its supports," he said. "The system's specialized FRP straps and tools affix the pads to the pipe, thus doing away with welding and epoxy for installation."

In addition, the design of the SmartBands and buckles prevent slipping, ensuring a watertight seal for the life of the system, while the SmartTool was purpose-built for tensioning.

"The installation process is straightforward, simple and can take no more than two minutes, on average," Almufti said. "After raising the pipe above its support, place the SmartPad underneath the pipe, loop the SmartBands around the pad, tighten the bands with the SmartTool, and finally cut off extra banding using the SmartTool."

The SmartPad system aims to significantly reduce overall cost of ownership, providing an estimated 25- to 30-year life cycle. The system is removable and reusable on same size pipes, can be installed on live lines, and functions in -60 F to 400 F (-51 C to 204 C) operating temperatures.

Case study

In December 2019, a chemical plant near the coast in south Texas was suffering from deep corrosion issues and was facing heavy fines and high premiums from their insurance carrier. The company decided to deploy the SmartPad System on a trial basis.

The company set aside three to four weeks for installation since it did its planning using the typical time it takes to install glue-on FRP wear pads. However, since the SmartPads do not require epoxy or welding, installation time was greatly reduced. Additionally, since the SmartPads do not use epoxy or a 24 hours cure time, installation crews could rapidly move from one section to another.

The initial phase was completed in only one week.

"The response to the SmartPad System had been extremely positive, and the system is now in use in two of the largest units of the plant," Almufti said. "The SmartPad system was used to protect aging sections that were critical to multiple systems in numerous units. Thousands of SmartPads are now in use in that plant and are performing well in the corrosive Gulf Coast environment.”

02.13.2024