Boskalis Offshore has introduced Namrod, a remot-ely controlled system for screening and sampling of seabed soils to water depths of 120 metres. It can dredge around platform bases for polluted muds and drill cuttings as well as clearing rubble prior to seabed installations.

Namrod is equipped with two booms. The first, used for excavation, can reach 2 metres below the seabed: it is fitted with a backhoe bucket or grab attachment to remove coarser seabed material. This cargo is then transferred to a dual-stage separator, a passive bar unit with rotating trommel for finer materials: the latter are directed into a collection hopper, via a belt conveyor, then pumped to the surface through an 8-inch pump and flexible hose.

A second, suction boom incorporates an electrically driven centrifugal pump system which can cope with solids up to 120mm diameter. Once larger particles have been removed by the excavation device, the suction head draws the sample area down to bedrock level for any finer materials remaining. The suction boom can also be fitted with a high-power jetting ring to break up solids.

Namrod sits on landing pads, adjustable remotely from the onboard control station to optimize screening and conveyor operations. The operator can also monitor the machine's inclination and screening system rotational speed. High resolution cameras give a clear view of excavation work, irrespective of water depths or darkness, according to Boskalis.

The system, which was originally developed for the Namibican Mining Corporation, can pump volumes at up to 450 cu m/hr and accommodate boulders up to 50cm wide.

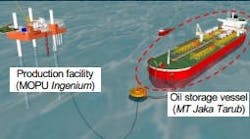

Neddrill drillships upgraded for long service off Brazil

The newly acquired drillship Neddrill Muravlenko, one of three contracted by Petrobras (Picture courtesy Neddrill).

Brazil's ultra-deep waters are one of the niche sectors where drilling contractor Neddrill is focusing its strategy. The Rotterdam-based company is also continuing to enlarge its fleet: currently it ranks 15 on the global list of rig owners.

At least three of Neddrill's drillships have gained a secure position in Brazilian waters for the coming five to six years. "The Brazil market looks good," says senior vice president sales and marketing, Ronald Hoope.

"Petrobras intends to reach 2,000 metres water depth in the year 2000, and we are preparing our vessels for these jobs. In October, Hydrill of Houston will deliver a new, ultra-deepwater BOP stack for use by the Neddrill 2."

This drillship has been working offshore Brazil since 1992 and will be upgraded for working in 1,800 metres of water. The new BOP equipment is the first in the deepwater market able to cope with 15,000psi pressures, according to Hoope.

Another drillship, the Neddrill 1, will move to Brazil mid-year. Currently it is completing an assignment in 1,400 metres of water off the coast of Angola. The vessel is equipped with a topdrive and DP.

The third drillship, Neddrill Muravlenko (ex-Viktor Muravlenko), is owned by Neddrill as part of a joint venture with Norway's Kvaerner Moss and Russia's Arcticmorneftegazvedka. This has also been contracted by Petrobras. Before moving south into the Atlantic it will be upgraded for drilling in 1,200 metres of water.

Neddrill is also considering taking a fourth drillship, Valentin Shashin, currently stacked in the Russian harbor of Murmasnk. This vessel would also be directed towards deep waters, either off Brazil or Africa.

North Sea prospects

Neddrill's only semisubmersible, the Neddrill 6, worked on various contracts on the UK continental shelf last year. This year it has been contracted by Lasmo and Deminex, but will later move to BP's Mungo Field, part of the ETAP project in the central North Sea.

Jack-up Neddrill 7 is in operation for BP in block 48/07. "This is a rolling type of contract," comments Hoope. "If the performance is good, another well can be drilled. We like this kind of incentive."

With the Neddrills 3, 4 and 9 currently in Dutch waters and the Neddrill 10 in Denmark (along with the accommodation rig Neddrill Kolskaya), the contractor has achieved a spread across the North Sea. The Kolskaya may also be converted back to drilling mode.

"In 1992," says Hoope, "we converted the rig into a hotel platform with 250 beds because of the good prospects in the accommodation market at that time. Today, however, the market does not look so great.

"We have stacked the derrick and other drilling equipment at a yard; but if we install this again, we might as well adapt the rig for working with 15,000psi pressure." In addition, his company is considering strengthening the Kolskaya's legs to enable it to work in deeper North Sea waters.

Varg modification

Norway's Saga Petroleum has again contracted the jack-up Neddrill Trigon for its Varg development. It used the rig in 1989 to kill high-pressure well 2/4-14 following a blow-out. The rig will move to Norway from southern Argentinian waters, where it has been drilling for Total Austral.

Its first stop in Europe will be Verolme Botlek's yard in Rotterdam for modification work. Currently the Trigon is certified by the Norwegian Petroleum Directorate for service in 72.5 metres of water: this will be extended to 85 metres through strengthening the legs and refurbishing the spud cans. The modification will also include installation of fully automated pipe handling equipment.

Neddrill sees 1998 as the critical year for drilling contractors, if the current upturn continues. "At that time," says Hoope, "90% of the existing rigs will be over 25 years old. If dayrates allow, contractors may consider building new rigs. It is certain that something must happen around 2000."

Copyright 1996 Offshore. All Rights Reserved.