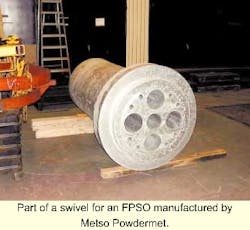

Part of a swivel for an FPSO manufactured by Metso Powdermet.

The largest component ever made using a Hot Isostatic Press (HIP) was completed in the factory of Metso Powdermet at Surahammar, Sweden this February. Measuring 2,600 mm x 1,290 mm, the unit weighs 14 tonnes and will form part of a swivel for the FPSO scheduled to operate on a North Sea (UK) field. The component was made from duplex stainless steel using the powder metallurgy process developed by Metso Powdermet's research staff. When installed the unit will be bolted to two smaller pieces weighing 9 tonnes and 3 tonnes which were also manufactured using the HIP process, forming the complete swivel unit.

The company, previously known as Santasalo Powerderment, has access to the world's largest hot isostatic press but the size of the largest swivel component made it necessary to complete the job in two stages. The press has an internal capacity measuring 3.1 m high and 1.35 m in diameter. This was only slightly larger than the finished size of the swivel piece - it was not possible for it to be made in one press operation due to the allowance for the shrinkage that occurs during the HIP process.

Intricate shapes

The HIP process was selected for this project because it allows very complex shapes such as manifolds and valve bodies to be manufactured from alloys that meet high standards of metallurgical integrity. When viewed under a microscope, the finished metal product will demonstrate a uniformly fine granular structure which is metallurgically superior to the longer and more inconsistent grains that result from other processes. The process has been refined to ensure full homogeneity throughout the entire structure of even the most complex workpiece. In some cases it has been found to be the only option available for the designers of components using special alloys that can be neither cast nor forged.

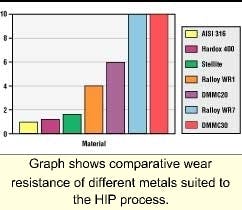

Graph shows comparative wear resistance of different metals suited to the HIP process.

The HIP manufacturing process involves the construction of a capsule out of sheet metal. This is an intricate procedure in which every detail of the work piece is shaped so that the capsule can serve as a completely air-tight mold for the finished item. The capsule is made larger than the finished product to allow for shrinkage, the extent of which is determined by careful calculations based on Powdermet's experience and FEM-calculations. By carefully controlling the size of the finished component it is possible to minimize the amount of machining required afterwards.

The nature of the Powdermet process makes it possible to manufacture components in any type of metal. These are supplied to the factory as a spherical powder with an average size of 125 microns. The powder is, nevertheless, sieved in-house to guarantee its quality. The capsule is filled with the powder after which the air is evacuated and the component is sealed. Once in the HIP the capsule is subjected to temperatures ranging from 1,130 - 1,180 deg C in an atmosphere of argon, which is used to create the extreme pressures needed in a carefully controlled process.

The work piece is likely to be in the HIP for up to 12 hours and on removal it is subjected to heat treatment and a pickling process that removes the carbon steel capsule and leaves the component ready for final finishing as required.

Composite capability

A valuable feature of the Powdermet process is its ability to produce components from composites of different metals. This enables the designer to address the problem of differing levels of wear resistance that may be required in the same component. A new group of Metal Matrix Composites (MMC) has recently been developed by Metso Powdermet which, by including varying ratios of, for example, carbides within the mixture now makes it possible to clad a component with a wear or erosion-resistant coating of varying thickness. This would typically involve the carbides being combined with duplex or super duplex to create a matrix capable of resisting both corrosion and erosion. This has been identified as a more cost-effective option than the usual alternative of overlay welding and may now be considered the optimum solution for sand separators and components exposed to drilling mud and cuttings.

For more information contact Göte Björman or Carl-Gustaf Hjorth, Metso Powdermet: tel +46 220 348 80, fax +46 220 334 90, Email: [email protected] or [email protected]