Operators breathe new life into old wells to support decarbonization efforts

Editor's note: This article first appeared in the 2024 Offshore Business Strategies Special Report, which published within the May/June 2024 issue of Offshore magazine.

By Garry Stephen, Oil States

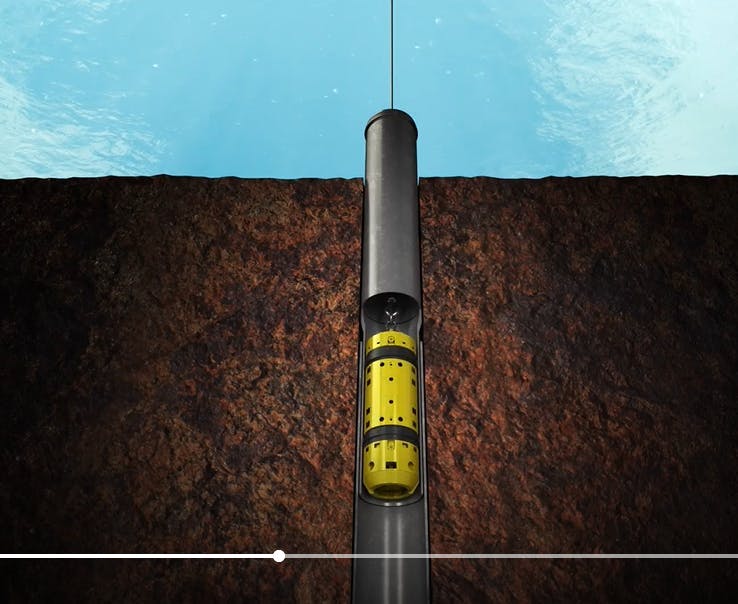

As oil and gas companies continue to seek ways to lower the carbon footprint of their operations, carbon capture and storage (CCS) looks promising. With CCS, CO2 emissions are captured, transported to CO2 storage sites and injected into geological formations deep underground where they remain indefinitely.

This aligns exceptionally well with oil and gas operations, as decommissioned wells are a great fit for injection sites. This type of activity is currently being seen in the North Sea. However, certain measures are needed to ensure these mature wells can be repurposed for CCS.

Transforming decommissioning

Traditionally, when all usable hydrocarbons have been extracted at the end of the oil and gas field production cycle, the topside facilities are dismantled, the wellbore is permanently plugged and abandoned (P&A), and the surrounding seabed is returned to its natural state. This decommissioning process is complex and incredibly expensive. This process also occurred more than 20 years ago in many instances. As operators look to use these mature wells for CCS, they discover that the original well abandonment architecture requires rework to be suitable for this new purpose.

P&A technologies, along with legislation, have evolved over the years. Due to geology, reservoirs repressurize back to 5,000 psi over time. A customized approach is needed to support operators seeking this type of decarbonization initiative. The availability of such bespoke strategies is timely, as the UK Continental Shelf (UKCS) alone is forecast to have a total of 2,164 wells decommissioned between 2023 and 2032, according to a report published by Statista in March of this year.

Field-proven P&A

The use of polymers in concrete today supports this effort, as it provides the flexibility necessary to respond to temperature and pressure changes on the seabed floor. New plugs not only need this flexibility but also need to be tested to confirm the ability to handle the repressurization that will naturally occur.

Oil States is actively working with offshore operators to enable them to repurpose mature wells and ensure newer wells can eventually be used for CCS programs as they’re decommissioned. To achieve this aim, it is critical to analyze each wellhead, the original P&A methodology and the P&A technology that was initially used for the well to properly determine the rework that must be performed.

In instances where wellheads have been removed and only stub pipe remains below the mudline, Oil States has established processes and equipment that could be utilized by operators to reestablish a wellhead using the company's range of swaging casing and informed isolation technologies, specifically Hydra-Lok and Enform. Providing the correct recommendation along with these customized technologies, using a range of connector sizes, enables the company to help operators maximize the CCS potential of mature wells.

Meeting future needs

The global push to reduce emissions is expected to increase the number of CCS projects in the coming years. As oil and gas operators seek to advance decarbonization for their own operations and the industry as a whole, remediating existing infrastructure is crucial to ensure the long-term storage viability of decommissioned assets. This presents exciting opportunities to not only promote greater sustainability in oil and gas but also turn decommissioned wells into a profit center by selling storage capacity to other companies.