Opens door for increased production

Ray Ravitz

Charlie Svoboda

M-I Swaco

Eliminating the need for costly and risky post-completion cleanup has been executed offshore California and the Gulf of Mexico where production has been shown to exceed expectations. A newly engineered reservoir drill-in fluid (RDF) that provides “channels” for the production of hydrocarbons was used.

The system was first applied offshore California in wells with limited production capacities. In the first application in state waters, the new system drilled 1,004 ft of 6 1/8-in. horizontal hole trouble-free and, despite a higher-than-desired solid content, the well came on line with gross production higher than expected. The solids build-up was lower in a second well, where the system was used to drill 920 ft of pay zone. The gross oil output exceeded expectations.

Unlike standard reservoir drill-in fluids, the new system employs organophilic material as part of the filter cake it deposits on the sand face. This material allows oil to flow through “channels” in the filter cake when the well is put on stream, thus eliminating the need for chemical breakers required for the clean-up process when conventional RDF systems are employed. The new generation system is designed for open-hole gravel packed and screen completions, especially when only low-pressure drawdown is available.

Reservoir protection

The characteristics of the filter cake deposited on the sandstone reservoir are of critical importance, especially for wells completed with open-hole gravel packs. In these instances the proper chemical and physical properties of the filter cake are essential to avoid both impairing the production reservoir and detrimentally impacting the planned completion procedure.

Reservoir drill-in fluids are engineered to lay down a filter cake that will block both fluid filtrate and drill solids from invading the pay zone. The deposition of an impermeable filter cake is particularly vital in various reservoirs completed open hole where perforations are not available to circumvent formation damage. Accordingly, during the gravel pack process the reservoir filter cake must be strong enough to prevent losses and premature screen out. After the well is completed, the filter cake ideally should be removed to prevent the gravel pack and completion screen from plugging.

Traditionally, cleaning up a reservoir filter cake has been accomplished with chemical breakers, including oxidizers, acid, enzymes, chelating agent solutions or a combination of a chelating agent and enzymes. The selected breaker is placed either during or immediately after the completion process, the latter of which makes it difficult to treat the entire filter cake resulting in only localized coverage. Conversely, adding the chemical breaker during the gravel pack operation poses the risk of premature filter cake breakthrough and partial destruction. This occurrence could prevent the reservoir from being completely packed with sand, opening the door for production-hampering filtrate and/or solids invasion.

The active filtercake resists water invasion of the formation while allowing hydrocarbons to flow at low flow-initiation pressures.

Attempts to externally treat and remove the filter cake often results in spotty dissolution, meaning the reservoir will be unable to produce at its maximum capacity. Furthermore, the breakthrough of aggressive chemical treatments may cause solids fines and chemicals to migrate into the formation under high differential pressure.

Active filter cake design

A decision was made to launch a development program aimed at engineering a reservoir drill-in fluid that would deposit an active filter cake whereby cleanup would be initiated by the produced oil as opposed to external measures. Although the active filter cake still lays down a protective barrier across the formation, hydrophobic components replace the conventional starch fluid-loss control agent and calcium carbonate bridging agent to produce an organophilic filter cake. The organophilic nature of the filter cake essentially creates “channels” to facilitate the flow of hydrocarbons through the filtercake, gravel and completion hardware and ultimately into the production tubulars. Overall, the overriding objective was for the system to be non-damaging to both the reservoir and completion assembly.

The active filter cake was designed on many of the same principles as conventional reservoir drill-in fluids in that it incorporated such critical property requirements as a proper rheological profile, filtration control, bridging and lubricity. With this system, the blends of bridging agents were optimized to protect the formation while filtration levels were controlled at the same levels.

A crucial component of the laboratory investigation was a series of formation damage tests to examine the concept of flowing hydrocarbons back through the filter cake confined by a gravel pack. The first tests comprised simple return permeability investigations to determine if the active filter cake by itself would damage the formation. These reservoir damage tests were conducted on Berea sandstone with no gravel pack.

The laboratory investigation revealed that when compared to conventional reservoir drill-in fluids, the active filtercake of the system in development generated acceptable return permeability values, while more importantly delivering lower flow initiation pressures. Two biopolymers were evaluated as primary viscosifiers, both demonstrating comparable performance.

Phase two of this stage of the development program consisted of an investigation into the impact of drilled solids on the performance of the system, especially active clays, can alter filtercake properties and make clean up more difficult. For the first series of tests up to 40 lb/bbl of OCMA clay - an excessive amount unlikely to be encountered in the field, but used to maximize impact -- were employed to simulate drill solids contamination. Once more, the return permeability tests were all very acceptable, while the flow initiation pressures of the active filter cake were much lower than that deposited by standard drill-in fluids.

The next step in the development process was to bring a gravel pack into the equation. This formation damage test included the establishment of irreducible water saturation after which the initial permeability to oil was investigated. The filter cake was deposited over a four-hour period and afterwards the core holder was depressurized, with extreme caution exercised to avoid inadvertently lifting off the filter cake. A 40/60 gravel pack and screen were subsequently placed on the filter cake prior to reassembling and pressurizing the core holder. Fluids were then tested with and without the 40 lb/bbl of solids contamination.

A conventional RDF used in the test delivered return permeability values about half of the unconfined filtercake values, in both “clean” and “dirty” formations. By comparison, the active filter cake technology showed return permeability values that were very comparable to unconfined values. In addition, flow initiation pressures were significantly lower than those of conventional drill-in fluids and lower than the unconfined values.

Final system composition

The new reservoir drill-in fluid was formulated with a minimal amount of bridging solids to protect the reservoir while maximizing solids control equipment efficiency and minimizing impairment of gravel pack completions. In addition to the specially designed hydrophobic carbonate component, conventional bridging agents were used to provide optimum particle size distributions for a wide range of formation pore sizes. The hydrophobic component is a very fine treated calcium carbonate chosen to maximize organophillic surface area, thereby maximizing organophillic channels while at the same time avoiding fine gravel pack and completion screen assembly plugging.

Monovalent salts, such as NaCl, KCl, NaBr, and Sodium Formate, can be incorporated to provide a wide density range from 8.33 to 12.5 lb/gal to minimize overbalance on the formation. It also is possible to use calcium chloride as a base brine to a density up to 10.8 ppg.

Shale and clays can be inhibited with the use of inhibitors employing cation exchange to control shale swelling. The chemistry of the system can be adjusted with salts or hydration suppressants to engineer a highly inhibitive fluid. The polymers, both a viscosifier and fluid loss control agent, work synergistically with these materials to impede the absorption of water by shales and / or formation clays.

The rheological properties can be created with various biopolymers. The rheological profile of this system exhibits an elevated low shear rate rheology while maintaining minimal high shear rate rheology, in particular minimal plastic viscosity. This type of rheological profile has demonstrated low pump pressures and excellent hole cleaning capabilities.

Due to its low solids and polymer nature, the system generally has a coefficient of friction of 0.2-0.25. This low coefficient of friction assists in rotary and oriented drilling operations. Lubricants have been found to further decrease the coefficient-of-friction to about 0.15.

The system is designed with a minimal number of additives that provide great latitude of flexibility. It is designed to be non-damaging by optimizing bridging, minimizing filtration, and maximizing flow of oil through filtercakes whether or not confined by gravel-packed completions without the need of a chemical breaker. Elevated low shear-rate viscosity (LSRV) alleviates drilling, hole cleaning, and wellbore stability concerns.

Depending on the make up brine, salt concentration, and desired LSRV, biopolymer viscosifier concentrations of 1.0-1.5 lb /bbl are used. Biopolymers can be added while drilling to maintain the LSRV.

As a water-base reservoir drill-in fluid, the system also minimizes the environmental concerns associated with its invert-emulsion counterparts. In addition, the flexibility of the system means it can be engineered with components that meet most environmental criteria worldwide.

Field results

One of the wide range of benefits of this system is its capacity to extract oil from reservoirs with limited productive capacity. The first opportunity to field test the system was in a horizontal open-hole gravel pack completion in California state waters. The lateral section was drilled with angles between 86° to 93° and was the first horizontal well to penetrate the G-5 sand. As the expected formation pressure was only 0.28 psi/ft or 6.7 ppg equivalent mud weight a low-density brine was required. The average permeability was conservatively calculated at 100 millidarcies with anticipated production of 90 b/d with 900 bbl of gross production.

Upon reaching total depth, the operator circulated the hole clean and pumped a viscous spacer with mutual solvent. This was followed by a pill comprising a solids-free version of the active filter cake system, which was left in the open-hole and 200 ft inside the casing. The operator displaced the well to a filtered 9.1/lb/gal KCL brine. Following this displacement, the operator ran a 3 1/2-in. wire-wrapped screen and 0.012-gauge liner in the hole before the well was gravel-packed with 20/40-mesh gravel.

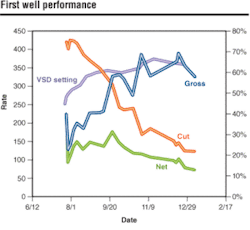

The system was first applied offshore California in a well that came on line with gross production higher than expected.

The operator put the well on stream without any external stimulation with chemical breakers. Initial test data revealed actual net oil production exceeded the 90 b/d target. However, the overall gross production initially was 250 b/d, which was below the 900 b/d expectation. Over a longer period, however, production exceeded the expected target. In addition, when compared to offset wells using conventional RDF systems it was determined the hydrophobic material in the filter cake likely had a lower permeability to water and a higher permeability to oil.

Upon analyzing the results of the initial well, the operator elected to again employ the active filter cake system in a vertical well in the same field. A low-density version of the system was displaced to the 6 1⁄2-in hole from the Ranger FO sand marker to the G5. The expected production was 65 b/d of net pay with gross production of 2100 b/d with a 98% cut.

A change in the surface equipment for this well allowed for more aggressive dilution. Samples taken at 100 ft intervals revealed that the highest concentration of drilled solids (2.51%) occurred as total depth was reached. Upon reaching TD, the same displacement procedures used on the first well were employed. Again, no chemical breakers were required when the well was put on line. Initial production test data showed net production of 147 b/d with gross production of 2136 b/d.

Production results from a third well off California and a well in the Gulf of Mexico were pending at this writing.•