Wayne Matlock, Lee Conn • M-I SWACO

A dry micronized weight material (MWM) designed to improve hydraulic pressure management while mitigating sag tendencies while drilling extended-reach wells has been developed and used successfully in recent Gulf of Mexico projects. The application of the MWM while drilling narrow hydraulic windows, typically observed in deepwater wells, has led to new breakthroughs in the ability to model and to manage the physio-chemical interactions of extremely small weighting agents with the chemicals and base fluids that constitute non-aqueous fluid (NAF) systems. These advances make it possible to design and apply weighted fluids that are ultra-thin and have significantly lower viscosity than fluids using traditional weighting materials.

Drilling grade barite

Of the 7.6 million tons of barite currently produced annually, approximately 6.7 million tons are used in drilling fluids. Since the early days, API drilling grade barite with the adopted density and particle size specifications has always been the preferred product for adjusting the weight of drilling fluids.

However, for the horizontal, small bore, extended long-reach, and other challenging drilling techniques employed routinely today, API specification barite can be troublesome. Other than the density requirements, API specification barite provides little value to a drilling fluid. Conversely, barite is prone to sag, and so requires viscosifiers and other gellants to keep it in suspension. In addition, drilled solids that incorporate into a drilling fluid quickly assume the particle size of API specification barite, resulting in reduced solids separation efficiency at the shakers and centrifuges.

Micronized barite

Conventional wisdom holds that micron-size particles are detrimental to drilling fluids because too many fines in the fluid increase rheology, a problem when drilling complex well geometries. However, extensive research and field experience has shown that reducing particle diameter by 100 reduces settling, or sag, by a factor of 10,000. With this development, barite is ground from an average of 75 to less than 5 um, with an average size of 1 to 3 um, or about one-eighth the size of a human blood cell. Consequently, the development of micronized barite for oil- and water-based drilling and completion fluids has opened the door for expanded applications of a material that has been the industry standard for nearly a century. Furthermore, breakthroughs in the ability to model and manage the physio-chemical interactions of extremely small weighting agents with the base oils comprising non-aqueous drilling fluids have challenged conventional wisdom on the rheology of weighted fluid systems.

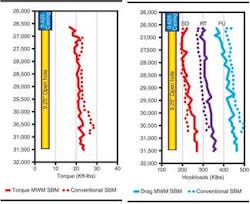

Torque and drag was reduced allowing the rotary to be increased from 90-100 rpm to 120-130 rpm.

These advancements in hydraulic modeling have cleared the way for the development of ultra-thin weighted fluids. In the field, these fluids have proven they can lower equivalent circulating densities (ECD), reduce surge and swab pressures, increase flow rates, and reduce pressure spikes, while possibly improving data transmission for downhole tools. Improving hole cleaning in highly deviated wells with higher rates of turbulent flow combined with their ability to bridge and plug fractures and permeable formations while reducing barite sag make these fluids suited for technically demanding applications. This would include but not be limited to the deepwater, ultra extended reach drilling (ERD) operations and the advancing development of mature reservoirs that exist in both cold and hot environments that create or destroy viscosity. This is a significant development in that approximately 45% of the world’s oil production comes from reservoirs that are passed peak production, thus generating increased interest in ERD, horizontal, through-tubing, and slim-hole drilling techniques to access reserves at the extremities of existing production zones.

ERD fluid challenges

Designing drilling and completion fluids for ERD and ultra ERD wells poses a host of technical challenges. Barite sag, fluid rheology/hole cleaning, hydraulics, management of equivalent circulating densities (ECD), wellbore stability, lubricity, and differential sticking are some of the considerations that must be taken into account.

Typically, invert emulsion drilling fluids are the systems of choice for the intermediate and lower intervals of a technically challenging ERD well.

Barite sag

While barite sag, or settlement, can occur in both invert emulsion and water-base drilling fluids, it generally is more severe in the former. Consequently, owing to invert emulsion fluids being the systems of choice for ERD and ultra-ERD applications, sag is one of the most prevailing problems that must be addressed in designing a fluid system for these operations.

Occurrences of barite sag have been observed over a relatively wide range of fluid densities from 11.7 to 20.0 ppg with weight variations as much as ±4.0 ppg exhibited in the flowline. Further, barite settling can occur under static or circulating conditions, or under both, and is affected by mud density, rheological properties, temperature, hole angle, size of suspended solids, and other factors.

Sag can be an offshoot of both unsuitable drilling fluid properties and improper drilling conditions and practices. Fluid properties affecting sag include rheology and the concentration and particle size distribution (PSD) of the solid particles dispersed in the fluid. Regardless of the cause and effects, the operational consequences of barite sag can include mud weight fluctuations, well-control problems, downhole mud losses, stuck pipe and/or casings, liners and packers, and possible wellbore instability. Field experience and lab research indicates that sag is most likely to occur in:

- 12 ¼-in and 8 ½-in. hole sections

- At angles greater than 30°, but is especially acute at 60° to 75°

- High temperature and/or high pressure downhole environments

- Mud weights in excess of 12 ppg

- ERD wells where ECD controls the maximum viscosity

- Casing designs with low annular velocities in deviated sections

- Lack of sufficient pipe rotation (greater than 90 rpm with 120-130 rpm preferred).

Another approach to minimizing sag in drilling fluids has been the use of weight materials with finer particle sizes. Stokes law established that the smaller a particle, the slower it is likely to settle. Owing to the shear increase in the number of particle-particle interactions, which cause an undesirable increase in the plastic viscosity, using fine materials for weighting drilling fluids tends to lead to high viscosity fluids.

All of these considerations plus the following must be taken into account when engineering a fluid for ERD applications:

- Poor hole cleaning can lead to development of cuttings beds, resulting in hole problems if correct drilling and tripping procedures are not followed

- The correct drilling fluid selection allows predictable fluid behavior and stable rheological properties under a variety of downhole conditions

- It is imperative that the long, high-angle sections indicative of many ERD wells are structurally stable and properly inhibited to prevent wellbore problems

- The increased step out of a typical ERD well requires a fit-for-purpose drilling fluid to impart the required weight and hydraulic pressure to the bit, plus a fluid possessing a low coefficient of friction (COF) while simultaneously assisting in directional operations

- Differential sticking can occur in the presence of a number of variables, including drilling into a permeable formation, fluid density in excess of formation pore pressure, pipe coming into contact with the formation, and the growth of a filter cake.

Ultra thin SBM

The ultra thin fluid employing micronized barite technology was developed as a high performing and cost effective alternative to the conventional SBM used in an ongoing deepwater GoM ERD program. The system would be used in the 9¼ in. (23.5 cm) production interval of its next ERD project, which was a 31,500 ft (9,600 m) MD well with 25,000 ft (7,620 m) of horizontal displacement.

In defiance of conventional wisdom on weighted-fluid rheology, the objective of the project-specific development program was to exploit breakthroughs in modeling and managing the physio-chemical interactions of extremely small weighting agents with the chemicals and base oils that constitute SBM systems. It was believed that these advances would make it possible to design an ultra thin weighted fluid that, for an appropriate project, can significantly lower ECD, reduce surge/swab pressures, increase flow rate, reduce SPP, reduce pressure spikes (surge/swab/initiate circulation), and possibly improve data transmission from downhole tools. All this while adequately cleaning the hole, bridging and plugging permeable formations and fractures, and preventing sag.

The successful development program would result in a fluid that could be used in any well where the combination of section length, drill pipe, and casing designed would create a negative hydraulic impact with conventional fluids. It was envisioned the system also could be used where sag may contribute to well control or issues surrounding the tripping/setting of drill pipe, casing, or liners. Overall, the aim was to design a SBM that would deliver a successful well, which otherwise would be unachievable.

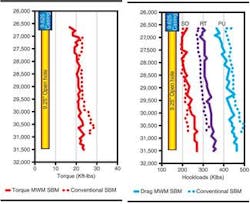

Field trial

The ultra thin SBM displaced a conventional synthetic-base fluid system to drill the final 4,000 ft (1,219 m) of a 9 1/4-in. (23.5-cm) production interval. Design challenges included hole cleaning issues on this 25,000 ft (7,620 m) horizontal displacement well complicated by the big bore 13 3/8-in. (34-cm) casing set at 80° and 18,000 ft of 9 5/8-in. (24.4-cm) liner. The success of the system would be measured as a comparison of the performance to a conventional SBM used in a similar offset well.

A number of criteria were earmarked as critical to success, with focus on the following:

- ECD – 0.3 ppg less than the offset at total depth

- Sag – Maximum of 0.3 ppg observed at the flowline

- GPM vs. SPP – 20% increase

- Reduction in downhole and surface losses

- Confirm accuracy of modeling software.

The strategy to reduce ECD focused on maintaining low shear viscosities at minimum values (6/3 rpm values of 2-4). Higher flow would be realized if high shear rates were minimized. Hole cleaning viscosity was replaced with higher annular velocity and rotary rpms. The drilling procedure included techniques to ensure the new hole drilled and casings would be cleaned. To accomplish this, a constant ROP and adequate circulation time between connections were maintained to ensure the “conveyor belt” of cuttings would be in balance, minimizing ECD fluctuations due to cuttings loading and chances for pack-offs. With the “conveyor belt” functioning properly, ROP was optimized using PWD real-time data and forward modeling with hydraulics software. To ensure the hole and casings were clean, a cleanup cycle was performed to include high pipe rotation and a minimum of four bottoms-up cycles.

Lessons learned

ECD, sag, and flow-rate/SPP targeted metrics were met or exceeded. Software modeling proved reliable and accurate providing results within + 0.1 ppg of PWD. Downhole and surface losses exceeded expectations but were attributed to an unforeseeable geologic event. The lower ECD MWM system was credited with minimizing losses. Hole cleaning was improved as indicated by cuttings lag time to the surface being reduced from 4 hours with the conventional fluid to 3.5 hours with the MWM system.

Since pilot program completion, the system has been used successfully in six Gulf of Mexico wells.

Cuttings appeared to be slightly larger with sharper edges, indicating less time spent between casing and drill pipe. Torque and drag was reduced allowing the rotary to be increased from 90-100 rpm to 120-130 rpm, further enhancing hole cleaning. Additional confirmation of torque and drag reduction was confirmed by the ability to rotate and work the liner to bottom through troublesome event encountered earlier.

The knowledge gain in the field trial concluded that it:

- Eliminates or greatly reduces sag and its associated problems

- Reduces ECD

- Enhances hole cleaning in high angle wells with higher AV and turbulent flow more likely

- Can be used successfully at higher flow rate at same SPP of 12-25%

- Lowers the pressure required to break circulation, which is particularly critical for enhancing MPD operations

- Is easy to maintain

- Lowers torque/drag

- Improves MWD transmission rate and quality

- Improves cementing

- Exhibits no settling even after extended static periods.

Acknowledgement

The authors thank the management of M-I SWACO for permission to present this paper.