Drilling unit's engines, mud tanks moved into pontoons to boost deckload

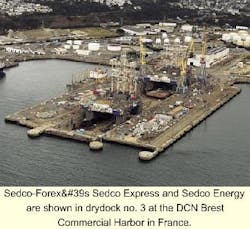

Sedco-Forex's Sedco Express and Sedco Energy are shown in drydock no. 3 at the DCN Brest Commercial Harbor in France.

With deepwater exploration working some 10 years in advance of development, today's newbuild semisubmersibles feature technical innovations intended to increase operator efficiency and improve vessel reliability. Importantly, these new semisubmersibles (semis) also are helping to reduce well construction costs. One such rig, the Sedco Express, due to be delivered at the end of this year, is rated for operation in 7,500 ft of water, with upgrades possible to 10,000 ft of water.

The fifth-generation semi is modular in design, with the 200-ft drilling rig derrick positioned at the stern of the deck. This design approach includes vertically racked pipe storage for improved pipe handling and increased deck space. The Sedco Express is dynamically positioned with the ABS class notation of XDPS3 - the highest rating possible, demonstrating full equipment redundancy for remaining on station while drilling.

Sister vessels Sedco Energy and Cajun Express, each due to be delivered in the first quarter 2000, also will be XDPS3 and will incorporate a mooring system, giving operators increased flexibility for stationkeeping. This option will allow operators to attend some shallow water locations where it is possible to avoid continuous use of thruster units or to moor the rig with a pre-laid mooring system, permitting long-term subsea developments.

Below-water mass

To improve deckload capacity while reducing total vessel weight, the Sedco-Forex semi is designed with most of it's mass below the water line. Strategic placement of the engine room and drilling mud tanks in the pontoons lowers the center of gravity and improves stability in rough waters.

The design innovation allows for a lighter deck structure for deepwater drilling and increased deck space for riser and drill pipe. The Sedco Express offers 30,000 sq ft of deck area and an operating deckload of 6,000 tons.

The design scheme calls for three 4.4-mW engines for each pontoon, presenting significant challenges for safe and efficient operations. ABS began working with Sedco-Forex during the preliminary design phase to assist the contractor in achieving safe, optimum performance. The endeavor proved challenging for resolving potential hazards within the context of the ABS rules and international regulations.

Pontoon trunks

Critical issues associated with explosions, fire protection, and water ingress have included effective ventilation and use of watertight fire dampers. Effective ventilation and engine exhaust removal from the pontoons is essential as the generator rooms and mud tanks represent a fire or explosion hazard. The diesel engines that drive these generators consume a large supply of air that needs to be fed to the generator room and then exhausted.

In terms of the configuration of equipment, Sedco-Forex located the ventilation and exhaust trunks within the inner "safe" area of the vessel columns, thus isolating them from areas exposed to potential waterline collisions.

At a diameter of 1.25 meters, the size of these ducts far exceeds the normal ventilation to pump rooms, which are usually the principal machinery located in the pontoons.

In addition to the ventilation ducts, engine exhaust, piping, electric power and control cables, access stairs, and a personnel elevator are fitted in the columns. To ensure personnel and equipment safety, the columns are built in a "double skin" arrangement so that the 11-meter by 11-meter trunk is not exposed to flooding in the event of a collision.

All ducts and pipes are designed, built and verified to prevent the possibility of progressive flooding. These precautions further ensure that if any watertight compartment in the rig is flooded, the water will be contained, avoiding a chain reaction that could ultimately lead to loss of the rig.

Among Sedco-Forex's several fire protection measures, watertight fire dampers were needed to isolate the sections of the exhaust trunking. In some locations, ABS approved ducting extended above the damage water line to eliminate the need for some fire dampers.

Structural design

With regard to the rig's structural design, two notable features included elastic supports for the quarters and a simplified cross bracing system. The quarters are mounted on resilient foundations, which reduces the loads passing through them and reduces the scantlings or use of steel.

The elastic or rubber supports, which will effectively quiet the transmission of noise from the drilling operations into the berthing areas, also facilitated fabrication of the quarters at a different location from the rest of the structure and allowed rapid assembly of the completed modules. With three separate yards in France working on the project, the modular approach proved efficient.

To provide improved access for support vessels, while reducing the risk of collision, Sedco-Forex opted to not use the more traditional vertical truss structure to connect the rig's structure. Instead, a simplified cross bracing system without vertical members extends between the rig's columns only below the operating water line, allowing supply boats to move in closer to the semi. The design approach also proved easier to build. ABS worked with Sedco-Forex to ensure that this system meets ABS' strength and fatigue requirements.

Construction of the Sedco Express and Sedco Energy is under way at DCN in Brest, France. The third unit, Cajun Express, is being built at the PPL yard in Singapore. Each has a long-term contract:

- Sedco Express is contracted to work for Elf off West Africa

- Sedco Energy is contracted to Texaco for work off Nigeria

- Cajun Express will work for Marathon in the Gulf of Mexico.

ABS is classing each of the semis, providing global support for design review and on-site technical assistance, along with surveys at the shipyards and vendor shops worldwide. Each of the semis will be classed XA1 Column Stabilized Drilling Unit XAMS XDPS3, ABS' highest class designation for a self-propelled semisubmersible drilling unit with unattended engine rooms and fully redundant dynamic positioning capability.

Author

Robert A. Major is a principal engineer with ABS Americas, responsible for proposals and project management of major classification projects, including Spars, tension leg platforms (TLP), and floating production storage and offloading (FPSO) systems. He has served as project manager for the Sedco Express, the Diana and King Spars, the Morpeth and Allegheny TLPs, and the Petrobras XXXIII and Petrobras XXXV FPSOs.

FRP grating further weight reduction measure

To further reduce weight on the Sedco Express semisubmersible, especially at the crucial upper level locations, fiberglass reinforced plastic (FRP) grating is used extensively. Weighing as little as one-fourth the weight of conventional steel grating, FRP grating offers equivalent strength characteristics, while giving the added benefits of being corrosion and chemical resistant, non-conductive/non-sparking, fire resistant, and having virtually no maintenance requirements.

Sedco-Forex designed the layout of the FRP grating in accordance with the latest industry standards. In areas with increased safety functions, including escape routes, firefighting stations, lifeboat stations, muster points, and others, the FRP grating design is tested to standards with increased fire resistance while maintaining sufficient load-carrying abilities. ABS reviewed the FRP grating arrangement, as submitted by the shipyard, to ensure consideration of all safety aspects.