Study assesses feasibility of Australia-Singapore interconnector

With high insolation levels, favorable conditions for wind farms and immense availability of land, Australia offers an attractive environment for large utility-scale renewable developments.

Developers have proposed projects to leverage this renewable energy potential to generate and export clean electricity to Southeast Asia, and Singapore in particular, through a subsea High Voltage Direct Current (HVDC) interconnector. It is one of the few credible options to help move the region towards a net zero future and, in the meantime, strengthen its energy security. The tri-party power link model is currently being implemented by the EuroAsia interconnector project between Israel, Cyprus and Greece.

In a recent study, global energy consultancy Xodus demonstrated the technical feasibility and quantified the environmental benefits of connecting Australia to Singapore.

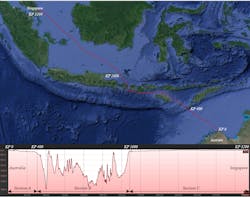

Interconnector marine route

The Aberdeen-headquartered company firstly identified a potentially suitable marine route estimated to be 3,200 km long with three main distinct sections. The first 400 km and last 1,600 km lie in relatively shallow waters, typically 100 m from external hazards, in addition to wave actions and sediment movements. At section B the water depth varies significantly with alternate deep and shallow sections and high gradients. The deepest section is at the Timor Trough where water depths reach 1,900 m and encounter high slopes.

The structure of the proposed cable will include a central conductor surrounded by insulation, armoring and an external sheath. By adopting current technology, the interconnector will most likely be configured in a bipolar mode to offer 2 to 3 GW power capacity, using two individual and identical HVDC underwater cables. In the event of one cable failure, the intact cable can be converted into monopolar mode with earth return over the repair duration, enabling half of the electricity capacity to be transmitted.

Typical linear weights of these subsea HVDC cables ranges from 40 kg/m to 60 kg/m with diameters in the order of 150 mm and a capacity exceeding 1 GW. It is estimated that the total cable weight of this interconnector would reach 300,000 to 400,000 tonnes.

Given the route length and variability, features could include different conductor materials, insulation technologies and armoring arrangements to account for constraints related to water depth, laying operations, seabed on-bottom stability, and protection against external damage.

Supply, transportation and installation

HVDC cable manufacturing requires specific know-how and capital-intensive power plants with facilities located in areas with well-established logistical infrastructures and marine access facilities.

Most long subsea HVDC interconnector projects executed to date were located within 500 to 1,000 km from the HVDC cable manufacturing facilities. This enabled the cable lay vessel (CLV) to act as the transport and installation vessel, transiting back and forth from the offshore cable route to the plant for reloading.

Typical CLV transit durations from Indonesia to Northern Europe, Southern Europe and Northeast Asia were estimated to be 37, 26 and 11 days, respectively (one way). Based on a CLV capacity of 10,000 tonnes (equivalent to approximately 200km of cable), a total of 32 vessel trips will be required to complete the entire interconnector offshore installation scope.

Depending on the number of simultaneous CLVs used for both transportation and installation (assuming one to three vessels) and the various plant locations, the overall cable installation campaign would last between two years (three CLVs and plants in Northeast Asia) to 11 years (one CLV and plants in Northern Europe), continuously.

It was concluded that an integrated approach combining CLVs and a fleet of heavy lift vessels fitted with high-capacity basket carousels will most likely be required to achieve an acceptable project delivery duration. In this situation, the CLVs would remain along the cable route vicinity during the entire installation campaign, while transport vessels journey back and forth from manufacturing plants to CLVs to ensure operational continuity and avoid excessive standby durations.

Carbon tax and emissions

To fairly estimate the actual net greenhouse gas (GHG) emissions of this type of project, a carbon lifecycle analysis of the embodied carbon of HVDC cables as well as the carbon emissions related to transportation, installation, operations and decommissioning, were undertaken.

Assuming an interconnector capacity of 2.4 GW associated with a 70% factor of charge (with adequate storage capacity, excluded from this assessment), approximately 15 TWh per annum of power generated by Singapore-based gas-fired plants can by replaced by clean Australian electricity, which corresponds to about 30% of Singapore’s annual electricity consumption.

The avoided emissions from Singapore’s gas-fired plants were estimated to reach 320 MteCO2e over 50 years – the typical design life of interconnectors. Conversely, a 10 GW solar plant coupled with an interconnector will generate 40 MteCO2e resulting in a net emission saving of approximately 280 MteCO2e over the project service life.

The cost of utility PV solar has decreased significantly over the past decade and this trend is expected to continue in the short and medium terms. As of today, the capital expenditure of a 10 GW solar farm with an intercontinental power link is estimated at $20 billion, with one third of the cost allocated to the subsea interconnector.

It is difficult to predict carbon tax over the next 50 years and a more refined cost model would be required to estimate the present value of this complex development. However, if the carbon tax in Singapore, currently set at approximately $4 per tonne of CO2e, reaches $10-20 per tonne of CO2e by 2030, this could result in $3-6 billion savings if 280 MteCO2e are not emitted from gas-fired plants. This simplistic calculation illustrates that carbon tax savings could, at least partially if not entirely, offset the cost of an intercontinental power link over its design life.

Conclusion

The Xodus study revealed that the Australia-Singapore interconnector project is technically feasible and can potentially offer valuable benefits, not only to both exporting and receiving countries, but also on the long-term to the entire region.

Most notably, over its 50-year design life, the link can reduce the carbon footprint of a country’s power generation system, traditionally dominated by fossil fuel, by a few hundred million tonnes of CO2. Further, projects of this nature will foster renewable energy integration at a continental level and enhance energy security. Ultimately, increasing climate concerns and carbon tax are likely to create credible business cases for intercontinental power links of this kind.