Rapid and efficient communications can be achieved with mobile personnel on offshore installations, using Ascom's wireless products. These facilitate swift response to events such as production breakdowns and accidents to personnel. The company's systems are in service on 90% of platforms in the Norwegian sector, according to Stefan Brämberg, vice president technology for Ascom Wireless Solutions.

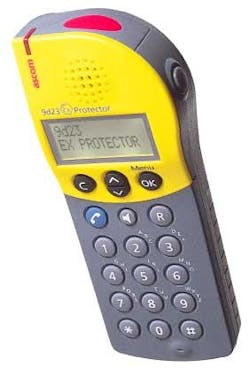

Ascom offers a complete range of mobile communications products including location devices, message receivers, and transmitters, alarm transmitters, and cordless and wireless telephones, including phones for use in hazardous areas, which now conform to the new Atex regulations.

The products can be customized to suit the environment in which they are used. A user moving around in a noisy environment such as the production plant on an offshore platform may be alerted to an incoming call or message by vibration rather than sound. The products can also be integrated with the customer's other systems.

Ascom has been developing on-site communications systems since the 1950s, and currently supplies 80% of the European market for paging systems. Its equipment operates with protected frequencies on the DECT – digital enhanced cordless telephony – platform for on-site communications.

The products have so many functions that the company should be seen as providing the pieces of a Lego system which can be put together in many different ways, according to the customer's needs – what Brämberg calls `smart integration'.

Central control is able to keep in close touch with all personnel dispersed around a work-site. If required, positioning systems are available which pinpoint the location of all users together with their identity. If an emergency arises requiring rapid on-site response, the nearest person can be identified and alerted. Messages can be sent from central control to an individual, a group or to all personnel.

The system can be set to operate on an escalating scale of alerts, so that if the first user does not respond, a second set of users is alerted. Once a user responds, the alerts cease.

Rapid mobilization of personnel to an event such as a production breakdown can lead to great savings for the customer compared with a delayed response due to inefficient communications, Brämberg says.

The equipment can be linked to the users' Internet provider, so that when they are out and about on the work-site they can be alerted to incoming emails, with brief details, if they are expecting an important message.

If something unexpected happens – an individual suffering a heart attack, for example, and therefore making no movement for a pre-set period of time – an alarm can be automatically sent to the central control.

One of Ascom's most established customers is Statoil, which uses its products on 12 of its offshore platforms in the Norwegian sector and at four onshore centers. It has also ordered products for use on the new Kristin platform. Seven of Norsk Hydro's installations also deploy the company's products, including Grane. Another customer is ConocoPhillips' Ekofisk complex.

For more information contact Stefan Brämberg, Ascom Wireless Solutions. Tel: +46 3155 9322, fax +46 3155 8313. [email protected], www.ascom.com/ws