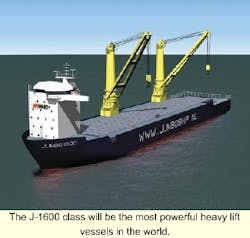

The J-1600 class will be the most powerful heavy lift vessels in the world.

With the growing lift and transportation needs of the oil and gas market in mind, Jumbo - the Dutch heavy transport specialist - has ordered two super heavy-lift vessels from Damen Shipyards of the Netherlands. The 11,000 dwt J-1600 class vessels, scheduled for delivery in 2003, will be the most powerful vessels of their type in the world, the company claims. Designed to meet the future requirements of a rapidly evolving industry, the vessels' equipment outfit takes into account the market's need for greater lift capacity and outreach.

The J-1600 class orders are in addition to the two H-800 class newbuilds ordered by Jumbo from the Madenci Gemi yard, based in Turkey. Work began on the first of the H-800 class newbuildings, Jumbo Vision, in February of this year. The 7,300 dwt vessel has a lift capacity of 800 tons. The sister vessel, Fairlane, will enter into service early next year.

The J-1600 class features two state-of-the-art rotating mast cranes with a combined lift capacity of 1,600 tons and a maximum outreach of 35 meters. For high-efficiency general cargo handling, the main hoists are supplemented with a range of other handling systems. With a shallow draft of just 6.5 meters, these newbuilds retain a flexible, small port operational capability.

Small port capability

Small ports have always played a key role in Jumbo's strategy, as many onshore rigs worldwide are constructed some distance away from main ports. Jumbo's Marketing and Communication Manager, Bert de Wolff, said that a "shallow draft vessel enables cargo discharge closer to the final destination and so reduces transportation costs. Where there are no port facilities and the solution is appropriate, Jumbo's draft flexibility enables our vessels to closely approach the shore and carry out a beach landing using barges."

In order to increase the J-1600 class vessels' operational versatility, the deckhouse and bridge are placed forward and only extend across half the deck width. This solution maximizes the vessel's longitudinal deck space, allowing for the comfortable accommodation of reactor columns, which can exceed 150 meters in length.

With an overall length of 143 meters, the main deck is completely flush, with a width of 26.5 meters. The deck can also accommodate wide modules; its width can be extended to 39.3 meters using "fly-decks." For an optimum underdeck stowage configuration, each tweendeck pontoon is variable in height, and standard underdeck height can be extended from 12.5 meters to 15 meters. Two main engines, rated at 4.320 KW, provide for speeds up to 17.5 knots.

Larger but modular

Bert de Wolff says: "Demand for greater capacity will continue to increase. Our market research shows a general trend to build larger and heavier modular components. This trend is the result of advancements in technology, the obvious drawbacks of on-site assembly, and safety-driven policies. The J-1600 series will provide the oil and gas industries with a safe, fast, and cost-effective means of transportation.

"We are optimistic about heavy lift prospects in the offshore market. We predict strong growth in demand for transportation services, as oil companies are expanding their exploration and production activities following a period of consolidation and relative stability in oil prices. In the floating production sector, for example, we expect a notable increase in the fabrication of process modules and turret and buoy systems, following firm growth in West Africa and Brazil and the future prospects in the Gulf of Mexico. Subsequently, the long-haul transportation market will be boosted by global sourcing."

Jumbo, a private company, was established over 30 years ago by the Dutch and British shipping families Kahn and Borchard. It operates a fleet of 10 dedicated heavy lift ships, including the new H-800 class Jumbo Vision. The ships range from the small B-type Stellamare, 88 meters in length, to the two D-type ships Jumbo Challenger and Fairmast, each capable of lifting 1,000 tons.

The fleet also includes three E-type vessels: Daniella, Stellaprima, and Fairlift - each with up to 650 tons lift capacity - and three handy-sized G-type class ships: Jumbo Spirit, Fairload, and Stellanova, all with 500 tons lift capacity. The four newbuilds coming on line over the next three years will double fleet capacity.

Recently, Fairmast transported subsea equipment for the 343,000 dwt Girassol - the world's largest floating producer. The contract, awarded by Alto Mar Girassol of France, involved the delivery of three riser towers from St Nazaire to offshore Angola. Each tower weighed 450 tons, with a length of 40.1 meters and a diameter of 9.73 meters.

The towers were loaded from trailers onto the Fairmast, using both vessel cranes. One tower was stowed on the tanktop, and the others were loaded on the main deck. Loading and seafastening operations were completed within three days. Following a 17-day voyage, Fairmast arrived and discharged the towers. Each tower was ballasted with 50 tons of fresh water - carried in one of the Fairmast's tanks - a requirement for the subsea installation of the towers.

Jumbo has also been contracted to provide heavy transport services for the Petronas Malaysia LNG project. This assignment requires two voyages, carrying components from Yatsushiro, Japan, to Bintulu, Malaysia. Both shipments, totaling some 15,000 cubic meters of cargo, include a 734-ton feed gas absorber with a length of 63.45 meters.

The first shipment was delivered in early March, and the second was scheduled to arrive in April. Later this year, Jumbo will transport two APCI-built heat exchangers, each 324 tons in weight and 54 meters long, for the same project.